A kind of manufacturing method of multifunctional industrial cloth

A manufacturing method and industrial technology, applied in the field of textile weaving, to achieve the effect of strong practicability and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

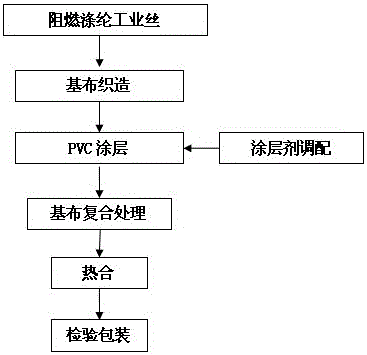

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the production method of cloth for double-layer composite tent

[0038] (1), base cloth parameters:

[0039] Use 1000d and 3000d flame-retardant polyester industrial yarns as warp and weft respectively for weaving, using rapier looms for weaving; base cloth weight obtained by weaving: 300g / m 2 .

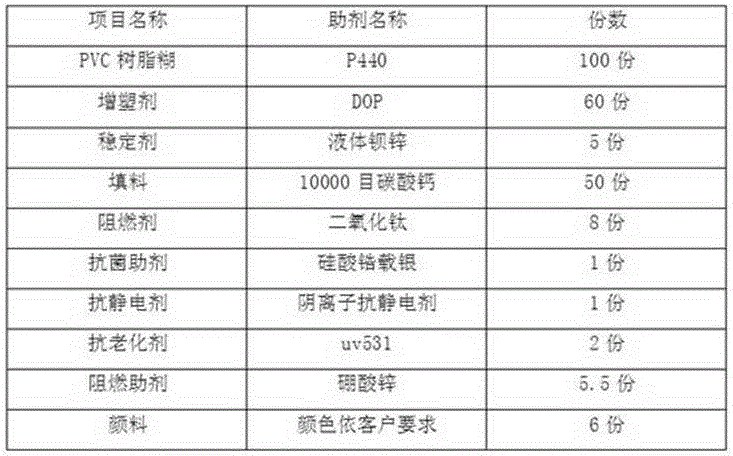

[0040] (2), coating processing:

[0041] The woven base fabric is sent to the coating system for coating processing, and the coating thickness is 310g / m 2 : Pass the 1000d×3000d polyester woven fabric with a density of 18×12 strands / cm through the coating machine at a uniform speed, add 1.6kg of cross-linking agent to every 100kg of coating agent, and evenly coat the coating agent mixture on the machine On the woven fabric; after drying in an oven at a drying temperature of 140°C, and then plasticized in an oven at a plasticizing temperature of 195°C, the product is obtained after surface treatment. Wherein, the surface treatment agent is acrylate.

[0042] ...

Embodiment 2

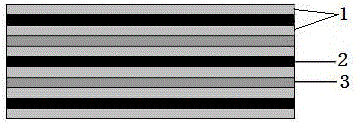

[0062] Embodiment 2: the production method of cloth for three-layer tent

[0063] (1), base cloth parameters:

[0064] 157g / m 2 , Weaving with 1000d and 1000d flame-retardant polyester industrial yarn. Weaving uses rapier looms.

[0065] (2), coating processing:

[0066] The finished base fabric is sent to the coating system for coating processing, and the coating thickness is 260g / m 2 : Pass the 1000d×1000d polyester woven fabric with a density of 14×12 strands / cm through the coating machine at a uniform speed, add 1.5kg of cross-linking agent to every 100kg of coating agent, and evenly coat the coating agent mixture on the machine on the fabric. It is dried in an oven at a drying temperature of 145°C, then plasticized in an oven at a plasticizing temperature of 200°C, and the product is obtained after surface treatment. Its surface treatment agent is acrylate.

[0067] Coating method: scraper

[0068] Coating drying temperature: 145°C

[0069] Plasticizing temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com