Preparation method of cubic silicon carbide film

A cubic silicon carbide and thin film technology, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve problems that cannot be eliminated and affect the promotion of silicon carbide thin films and related devices, so as to reduce energy consumption, The effect of reducing crystal defects and increasing the deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

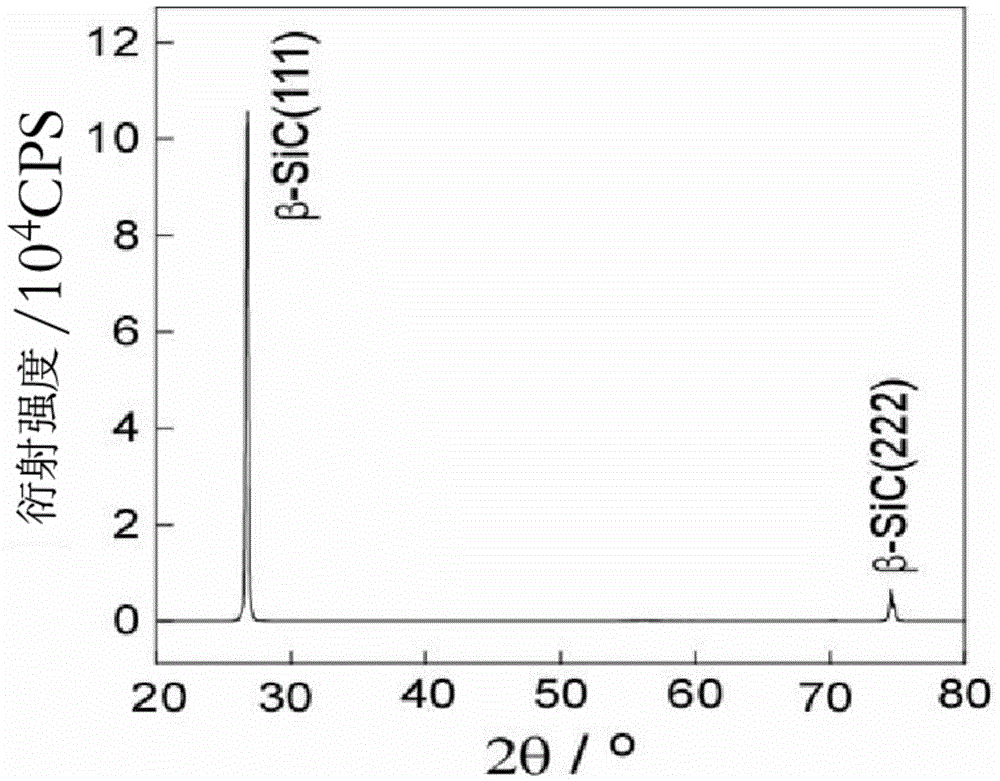

Image

Examples

Embodiment 1

[0026] A method for preparing a cubic silicon carbide film, comprising the steps of:

[0027] (1) Put the monocrystalline silicon substrate on the substrate seat of the cold-wall laser chemical vapor deposition reactor, adjust the vacuum degree to below 10Pa, and set the heating system in the reactor to raise the temperature of the substrate seat to 300°C ;

[0028] (2) The carrier gas Ar gas containing hexamethyldisilane (HMDS) is passed into the reactor, the flow rate of HMDS is 3 sccm, and the vacuum degree in the reactor is 10000Pa by adjusting the vacuum pump exhaust valve;

[0029] (3) load a continuous laser to irradiate the surface of the silicon substrate, the wavelength is 808 nanometers, the laser power is adjusted to 80W, and the laser loading time is 10 minutes;

[0030] (4) Stop feeding the Ar gas containing HMDS, turn off the laser and the heating system in the reactor, evacuate, adjust the vacuum in the reactor to below 10Pa, and naturally cool to room tempera...

Embodiment 2

[0036] A method for preparing a cubic silicon carbide film, comprising the steps of:

[0037] (1) Put the monocrystalline silicon substrate on the substrate seat of the cold-wall laser chemical vapor deposition reactor, adjust the vacuum degree to below 10Pa, and set the heating system in the reactor to raise the temperature of the substrate seat to 600°C ;

[0038] (2) The carrier gas Ar gas containing hexamethyldisilane (HMDS) is passed into the reactor, the flow rate of HMDS is 10 sccm, and the vacuum degree in the adjustment reactor is 1000Pa;

[0039](3) load a continuous laser to irradiate the surface of the silicon substrate, the wavelength is 1080 nanometers, the laser power is adjusted to 20W, and the laser loading time is 3 minutes;

[0040] (4) Stop feeding the H containing HMDS 2 , turn off the laser and the heating system in the reactor, evacuate, adjust the vacuum in the reactor to below 10Pa, and cool naturally to room temperature to obtain a cubic silicon car...

Embodiment 3

[0043] A method for preparing a cubic silicon carbide film, comprising the steps of:

[0044] (1) Put the monocrystalline silicon substrate on the substrate seat of the cold-wall laser chemical vapor deposition reactor, adjust the vacuum degree to below 10Pa, and set the heating system in the reactor to raise the temperature of the substrate seat to 900°C ;

[0045] (2) The carrier gas H containing hexamethyldisilane (HMDS) 2 Pass in the reactor, the flow rate of HMDS is 18sccm, and the vacuum degree in the adjustment reactor is 100Pa;

[0046] (3) Loading a continuous laser to irradiate the surface of the silicon substrate, the laser wavelength is 1080 nanometers, the laser power is adjusted to 150W, and the laser loading time is 1 minute;

[0047] (4) Stop feeding the carrier gas H containing HMDS 2 , turn off the laser and the heating system in the reactor, evacuate, adjust the vacuum in the reactor to below 10Pa, and cool naturally to room temperature to obtain a cubic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com