A method and device for preparing composite metal materials by spraying and spraying

A technology of composite metal materials and spraying method, which is applied in the field of materials, can solve the problems of difficulty in ensuring safety, low radiation heating efficiency, and affecting heating effects, etc., and achieve the effects of safety assurance, simple equipment, and enhanced bonding effect and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

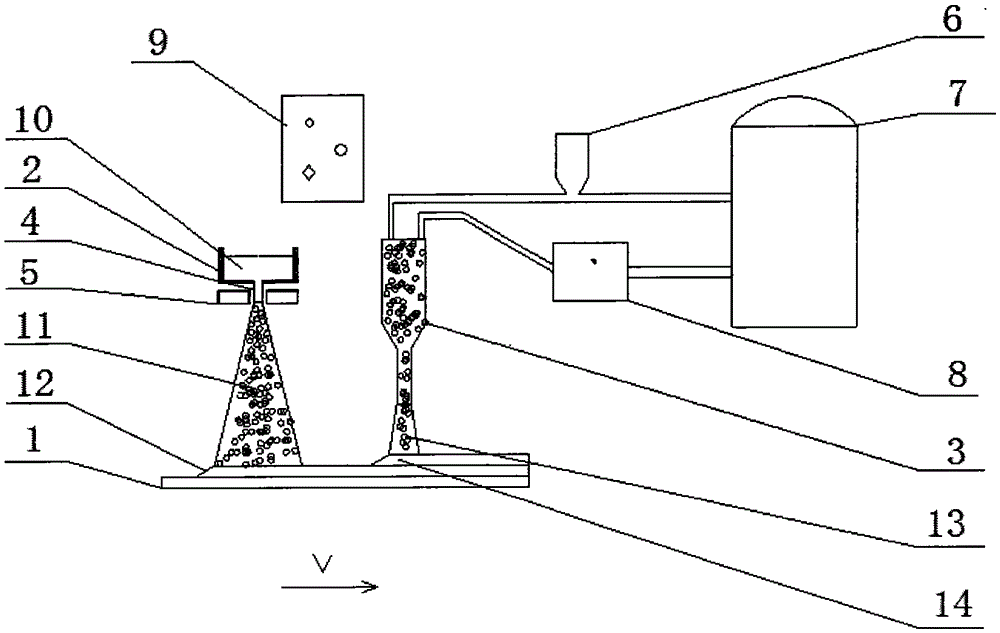

[0023] Example 1. A crucible and spray gun are arranged above the deposition substrate. At first, the deposition substrate moves from right to left at a speed of 10mm / s, the spray atomized metal is plain carbon steel, the metal atomization temperature is 1600°C, the thickness of the metal deposition layer formed by atomization spray is 12mm, and the metal atomization pressure is 1.5 MPa. After the metal deposition layer is formed, the deposition substrate moves to the bottom of the spray gun. The composite metal is low-carbon steel. The average particle size of the composite metal particles is 50 μm. The temperature of the metal deposition layer before spraying is about 900 ° C. The pressure of the high-pressure compressed gas in the spray gun At 2.0MPa, the thickness of the composite bonding layer is 3mm.

Embodiment 2

[0024]Example 2. Arrange the crucible and spray gun above the deposition substrate. At first, the deposition substrate moves from right to left at a speed of 12mm / s. The atomized metal is ordinary carbon steel. The metal atomization temperature is 1590°C. is 10mm, and the metal atomization pressure is 1.2MPa. After the metal deposition layer is formed, the deposition substrate moves to the bottom of the spray gun. The composite metal is low-carbon steel. The average particle size of the composite metal particles is 60 μm. The temperature of the metal deposition layer before spraying is about 1000°C. At 1.8MPa, the thickness of the composite bonding layer is 2mm.

Embodiment 3

[0025] Example 3. A crucible and spray gun are arranged above the deposition substrate. At first, the deposition substrate moves from right to left at a speed of 13mm / s, the spray atomized metal is plain carbon steel, the metal atomization temperature is 1620°C, the thickness of the metal deposition layer formed by atomization spray is 15mm, and the metal atomization pressure is 1.0 MPa. After the metal deposition layer is formed, the deposition substrate moves to the bottom of the spray gun. The composite metal is low-carbon steel. The average particle size of the composite metal particles is 70 μm. The metal temperature of the metal deposition layer before spraying is about 950 ° C. The pressure of the high-pressure compressed gas in the spray gun Controlled at 1.5MPa, the thickness of the composite bonding layer is 1.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com