High-strength bainite steel rail and production method thereof

A production method and bainite technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as cracks, wear to the limit, peeling off blocks, etc., and achieve excellent mechanical properties, good strength and toughness matching, and low alloy content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the following, a high-strength bainitic steel rail and its production method in the present invention will be described in detail with reference to examples.

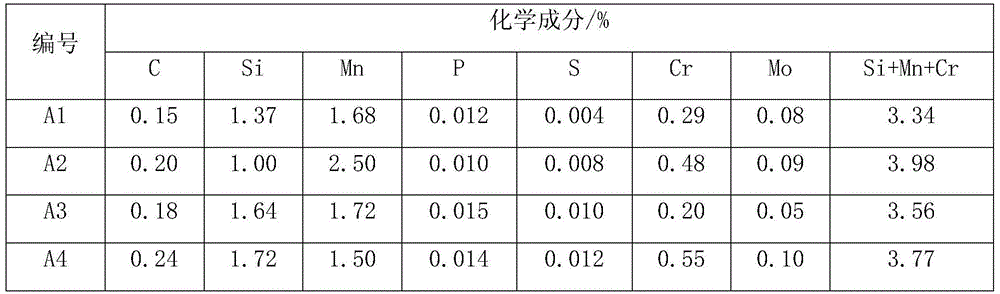

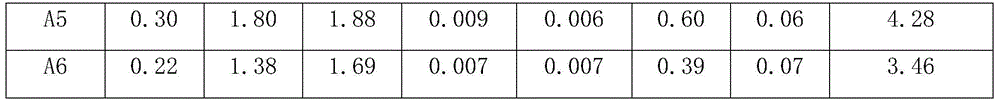

[0027] The embodiment and comparative example of the present invention select the chemical composition of six groups of bainite rails in Table 1 and Table 2 respectively. Wherein, the comparative example is the chemical composition of the bainite rail in the prior art.

[0028] Table 1 Chemical composition of six groups of examples

[0029]

[0030] Continued Table 1

[0031]

[0032] Table 2 Chemical composition of comparative examples

[0033]

[0034] The steel slabs containing the components described in the examples and comparative examples were all rolled into 60kg / m rails, and the corresponding serial numbers adopted the same accelerated cooling start and finish cooling temperatures within the error range as shown in Table 3.

[0035] Six groups of embodiments and comparative examples proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com