Method for preparing hydroxymethylated stalk ethanol byproduct and composite wood adhesive

A wood adhesive and methylolation technology, applied in the direction of aldehyde/ketone condensation polymer adhesive, adhesive, adhesive type, etc., can solve the problems of poor water resistance, complex composition and low activity of urea-formaldehyde resin, Achieve good preloading and curing performance, save oil resources, and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Preparation of hydroxymethylated straw ethanol by-products

[0024] 1) Add 128.5g of water, 210.4g of straw ethanol by-products, and 27.7g of 36.8wt.% formaldehyde solution into a 500mL reactor, adjust the pH value to 7.0 with ammonia water, and stir for 10 minutes;

[0025] 2) Adjust the pH value of the mixing system in the reactor to 7.0 with ammonia water, then raise the temperature to 70°C, and react for 2 hours;

[0026] 3) After adjusting the pH value of the mixing system in the reactor to 6.6 with ammonia water, cool down to 50°C, add 4.5g of urea, react for 10min, cool to room temperature and discharge; test their properties respectively, and the results are listed in Attached Table 2.

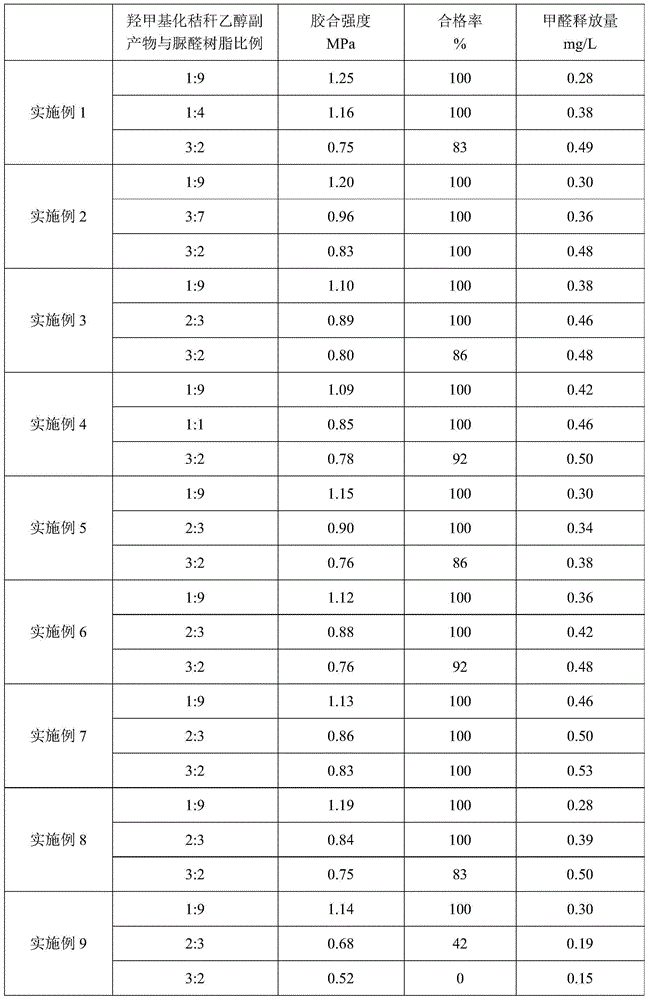

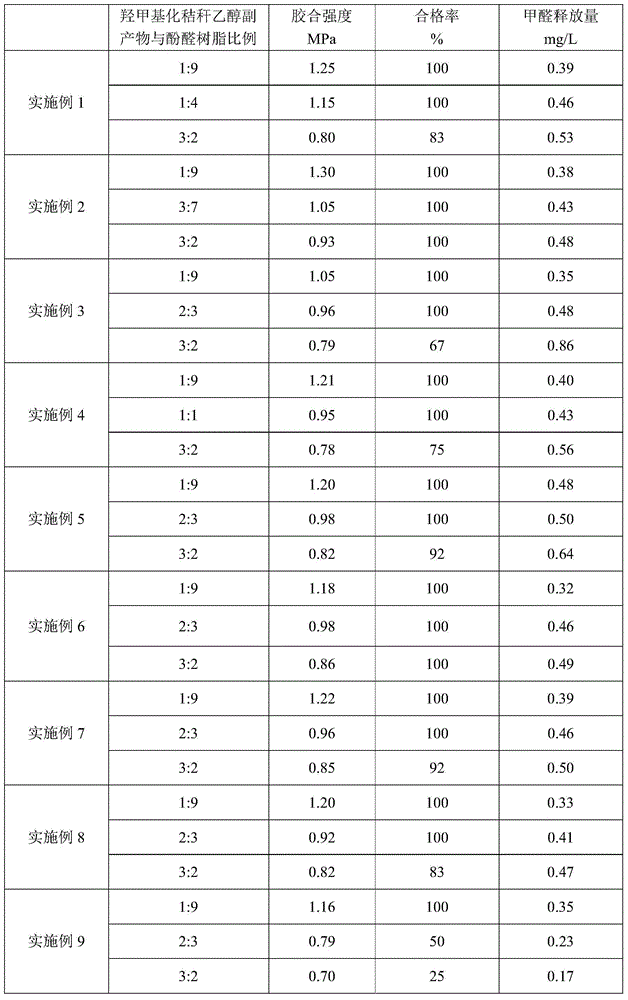

[0027] Preparation of straw ethanol by-product-urea-formaldehyde resin composite adhesive: the hydroxymethylated straw ethanol by-product and urea-formaldehyde resin prepared in the first step were mixed at room temperature at a mass ratio of 1:9, 2:3, 3 : 2 mixing, and...

Embodiment 2

[0030] Step 1: Preparation of hydroxymethylated straw ethanol by-products

[0031] 1) Add 151.0g of water, 209.8g of straw ethanol by-products, 27.7g of 36.8wt.% formaldehyde solution into a 500mL reactor, adjust the pH value to 7.4 with 25wt.% hexamethylenetetramine solution, and stir for 30min;

[0032] 2) After adjusting the pH value of the mixing system in the reactor to 7.4 with 25wt.% hexamethylenetetramine solution, the temperature was raised to 75°C and reacted for 2 hours;

[0033] 3) Use 25wt.% hexamethylenetetramine solution to adjust the pH value of the mixing system in the reactor to 7.6, then cool down to 60°C, add 6.3g of melamine, react for 10min, cool to room temperature and discharge; test their properties respectively, The results are listed in Appendix Table 2.

[0034] Preparation of straw ethanol by-product-urea-formaldehyde resin composite adhesive: the hydroxymethylated straw ethanol by-product and urea-formaldehyde resin prepared in the first step wer...

Embodiment 3

[0037] Step 1: Preparation of hydroxymethylated straw ethanol by-products

[0038] 1) Add 168.8g of water, 208.6g of straw ethanol by-products, 27.7g of 36.8wt.% formaldehyde solution into a 500mL reactor, adjust the pH value to 8.1 with 30wt.% NaOH solution, and stir for 50min;

[0039] 2) After adjusting the pH value of the mixing system in the reactor to 8.2 with 30wt.% NaOH solution, the temperature was raised to 80°C and reacted for 2.5h;

[0040] 3) Use 30wt.% NaOH solution to adjust the pH value of the mixing system in the reactor to 8.2, then cool down to 70°C, add 4.5g of urea, react for 10min, cool to room temperature and discharge; test their properties respectively, and the results are listed in the attached table 2.

[0041] Preparation of straw ethanol by-product-urea-formaldehyde resin composite adhesive: the hydroxymethylated straw ethanol by-product and urea-formaldehyde resin prepared in the first step were mixed at room temperature at a mass ratio of 3:7, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com