Flexible rare-earth transparent light-emitting film and preparation method thereof

A luminescent film and rare earth luminescent technology, which is applied in the preparation of flexible rare earth transparent luminescent film, high-efficiency, transparent luminescent film field, can solve the problems of long reaction cycle, cumbersome synthesis and purification steps, high synthesis cost, etc., achieve simple method, improve dissolution High concentration and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Take 1g of laponite LAPONITE RD in a 100ml flask, add 15ml of double-distilled water to dissolve, ultrasonicate, and stir with a glass rod until it is in a transparent gel state (about 30min), then add 10ml of 0.1mol / L EuCl to it 3 ·6H 2 O ethanol solution, refluxed in an oil bath at 80°C for 24h. After centrifugation and drying, the ion-exchanged water-soluble gel-state nanoclay is obtained, which is designated as LA-Eu.

[0043] (2) Take 0.29g (1.308mmol,) α-thienoyltrifluoroacetone (TTA) in a 100ml flask (the molar number of Ln ions is excessive relative to TTA), add 10ml of absolute ethanol to dissolve, and then dissolve the condensate obtained in the previous step LA-Eu in the gel state was added to the flask, ultrasonicated, and then 6ml of absolute ethanol was added, reacted for 5 hours, centrifuged, and dried to obtain a water-soluble gel-state nanoclay containing luminescent rare earth organic ligands, which was designated as LA-EuTTA.

[0044] (3) Take t...

Embodiment 2

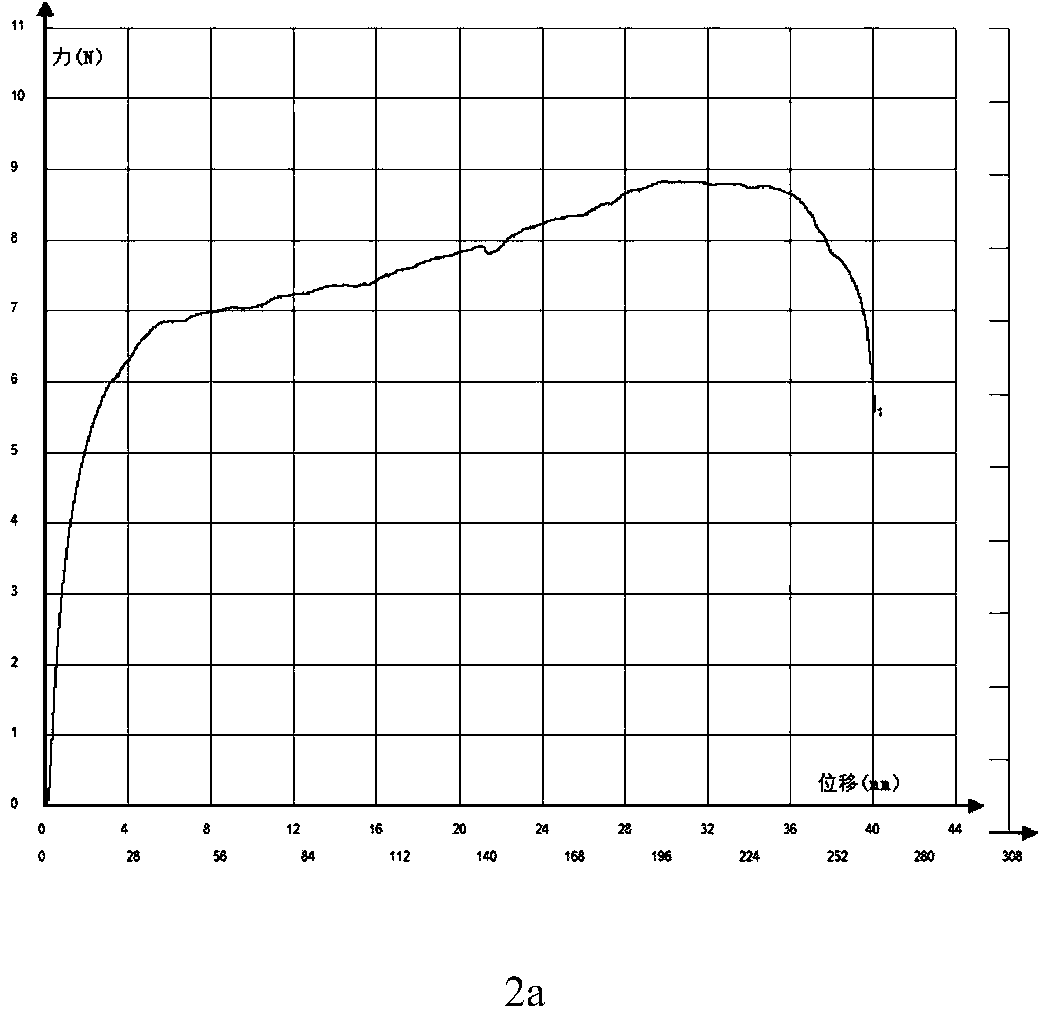

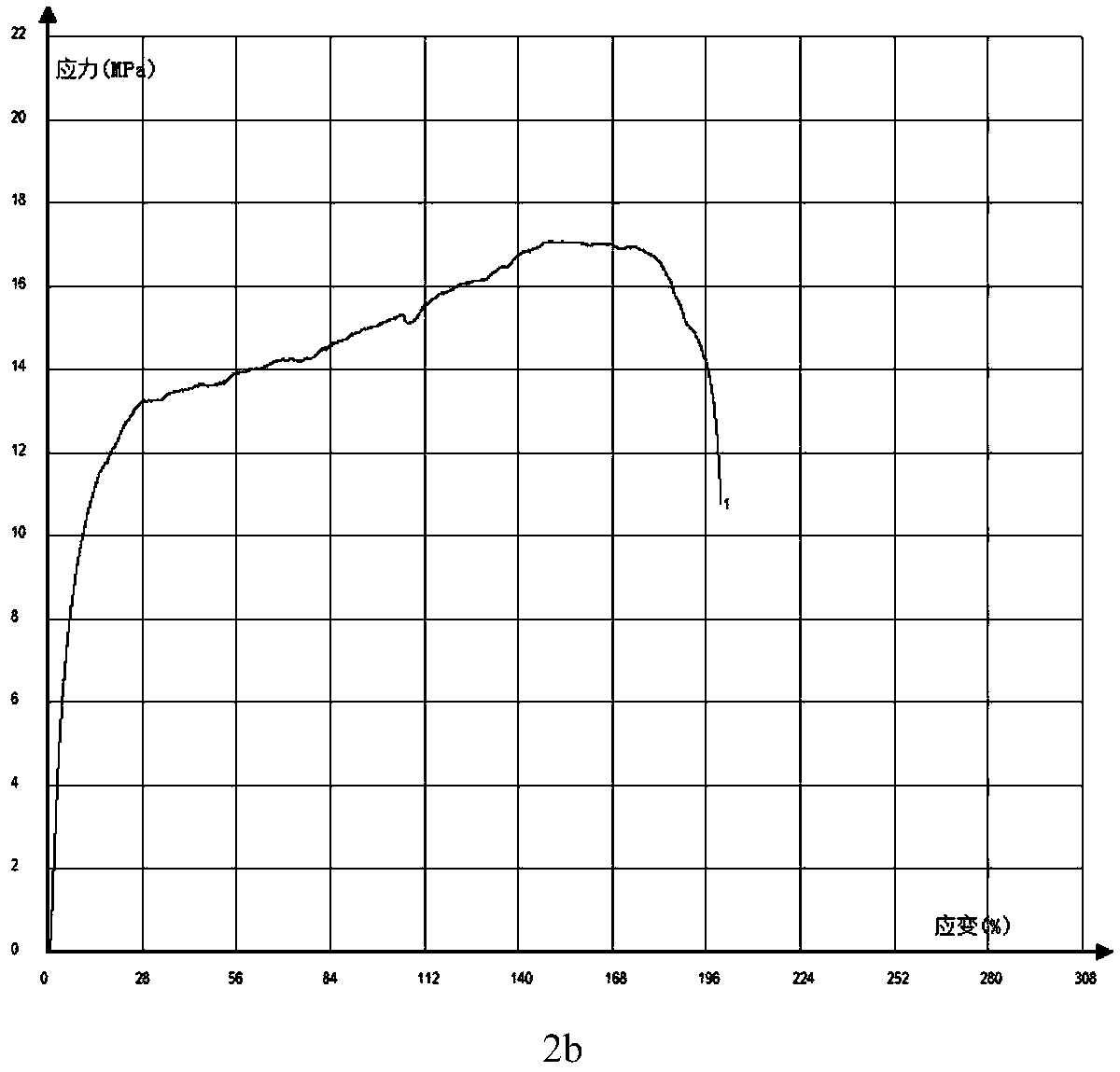

[0048] Steps (1) and (2) are the same as in Example 1, but the silanized ionic liquid II in steps (3) and (4) is changed to N-acetonyl pyridinium chloride, and other conditions remain unchanged, and finally a transparent luminescent film LA is obtained. -EuTTA-VIII-PVA. The film also has light, thin, uniform and transparent properties as in Example 1, and has good tensile properties. Image 6 It is the mechanical performance test of the flexible transparent light-emitting film in Example 1. Among them, a is the force and displacement diagram of the tensile test, and it can be seen from the figure that the tensile displacement can exceed 44mm. Where b is the stress-strain diagram of the tensile test, from which it can be seen that the elongation at break can reach 264.56%, and the maximum stress can reach 10MPa. Figure 7 It is the excitation spectrum figure of the flexible transparent luminescent film in embodiment 2, Figure 8 The emission spectrum of the flexible transpar...

Embodiment 3

[0050] Steps (1) and (2) are the same as in Example 1, but the silanized ionic liquid II in steps (3) and (4) is changed to a hydroxyl ionic liquid, and other conditions remain unchanged, and finally a transparent luminescent film LA-EuTTA-VII is obtained -PVA. The film also has light, thin, uniform and transparent properties as in Example 1, and has good tensile properties. Under the ultraviolet light, the luminescent material also exhibits obvious bright red. The maximum emission wavelength of the film is located at 612nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Maximum stress | aaaaa | aaaaa |

| Maximum emission wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com