High flaming retarding MPP power protecting tube

A power protection and high flame retardant technology, applied in the field of high flame retardant MPP power protection tubes, can solve the problems of high elasticity of melt extrusion and large flexibility of PP molecular chains, so as to improve the degree of crystallization, rigidity and lubricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

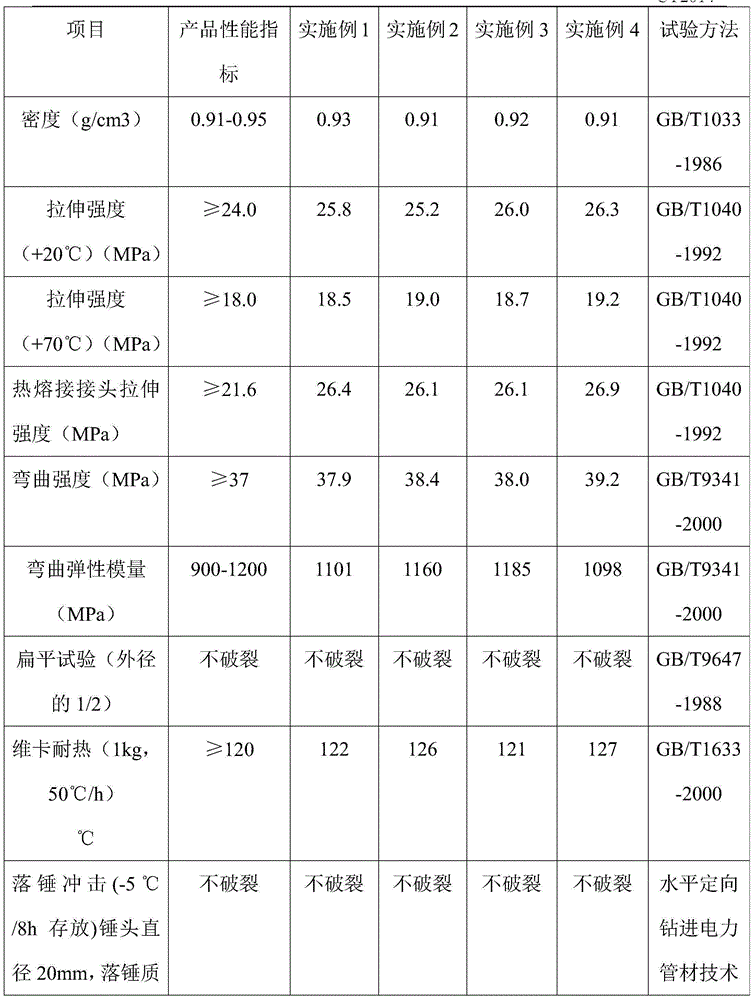

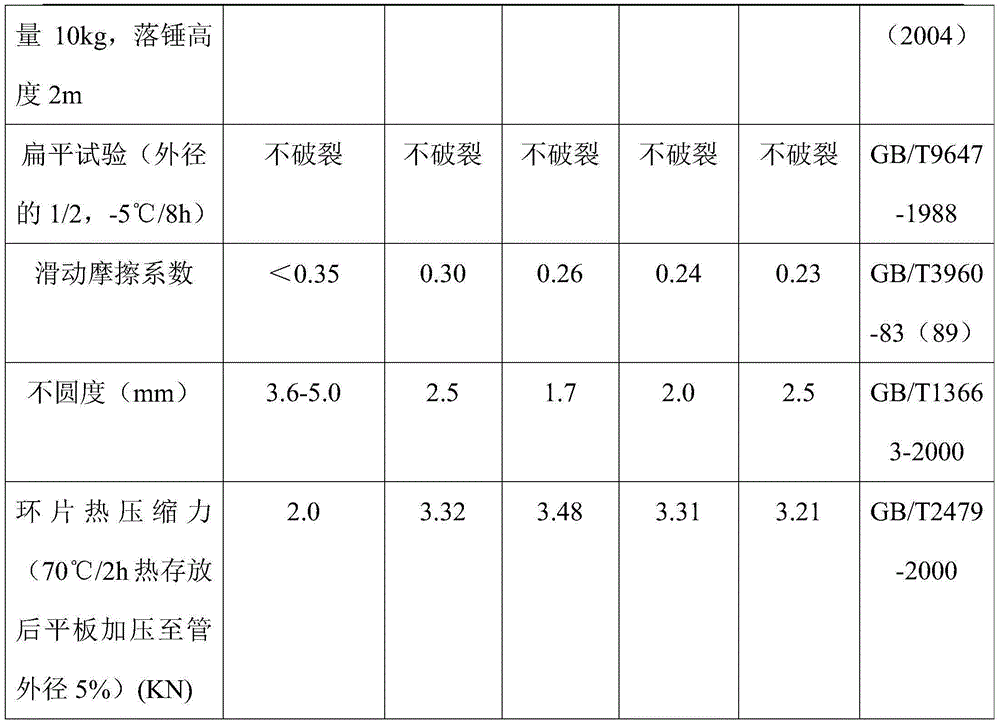

Embodiment 1

[0025] The high flame-retardant MPP power protection pipe of the present invention has a raw material composition as shown in Example 1 in Table 1, and the modified whisker is a surfactant-modified basic magnesium sulfate whisker, and is prepared by the following process: Add 13 parts of basic magnesium sulfate whiskers and 166ml of deionized water in the three-necked flask while stirring, then add 0.5 parts of calcium dodecylbenzenesulfonate and 1 part of dimethyl azobisisobutyrate, and heat to 70 °C, add 19 parts of methacrylate within 1 hour, then suction filter, wash and dry to obtain modified whiskers;

[0026]According to the ratio of raw materials in Example 1 in Table 1, the high flame-retardant MPP power protection pipe is prepared according to the following preparation process: each raw material is added to a high-speed mixer at the same time and mixed for 10 minutes to obtain a mixture; The temperature of the front roll of the mill is 50°C, the temperature of the re...

Embodiment 2

[0028] The high flame-retardant MPP power protection pipe of the present invention has a raw material composition as shown in Example 2 in Table 1, wherein the modified micro-silica powder modifier adopts KH-550; the particle diameter of the nano-mica adopts 56nm; The modifying agent of the modified shell powder adopts furfural;

[0029] The modified whiskers are surfactant-modified basic magnesium sulfate whiskers, and are prepared by the following process: 10 parts of basic magnesium sulfate whiskers and 150 ml of deionized water are added in a three-necked flask while stirring, and then 0.3 Part of sodium dodecylbenzene sulfonate, 0.2 part of dialkylbenzene sodium sulfonate and 0.5 part of benzoyl peroxide, heated to 90°C, adding 16 parts of methacrylate within 1.1h, suction filtration, washing, drying to obtain modified whiskers;

[0030] According to the ratio of raw materials in Example 2 in Table 1, the high flame-retardant MPP electric power protection pipe is prepare...

Embodiment 3

[0032] The high flame-retardant MPP power protection pipe of the present invention has a raw material composition as shown in Example 3 in Table 1, wherein the modified micro-silica powder modifiers are KH-151 and KH-171; the nano-mica The particle diameter is 68nm; The modifying agent of described modified shell powder is pimelic acid and glutaric acid;

[0033] The modified whiskers are surfactant-modified basic magnesium sulfate whiskers, and are prepared by the following process: 15 parts of basic magnesium sulfate whiskers and 250 ml of deionized water are added in a three-necked flask while stirring, and then 0.8 1 part of sodium dialkylbenzenesulfonate, 0.5 part of sodium persulfate and 0.4 part of ammonium persulfate, heated to 72°C, adding 20 parts of methacrylate within 1.5 hours, then suction filtered, washed and dried to obtain modified whiskers ;

[0034] According to the ratio of raw materials in Example 3 in Table 1, the high flame-retardant MPP electric power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com