A kind of polypropylene modified polyurethane sponge and its preparation method and application

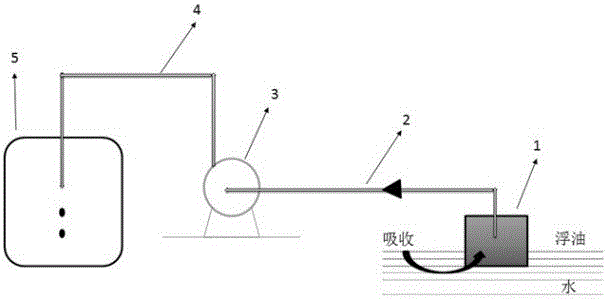

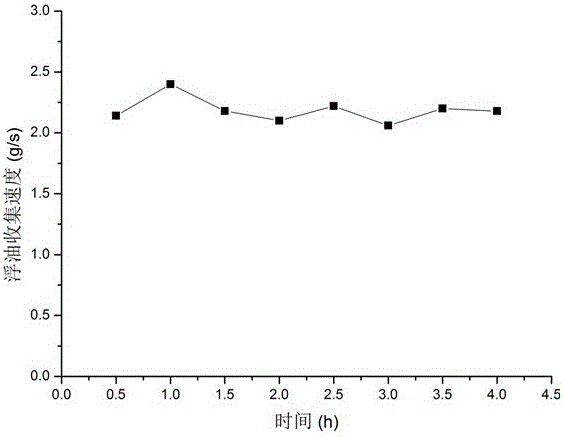

A polyurethane sponge, polypropylene technology, applied in separation methods, grease/oily substance/float removal devices, liquid separation and other directions, can solve problems such as easy imbalance, secondary pollution, inflexible oil absorption devices, etc. Install simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention adopts dipping coating method to modify polyurethane sponge to obtain polypropylene modified polyurethane sponge, which specifically includes the following steps: dissolving polypropylene particles (melt index: 12g / 10min) in two In toluene, a polypropylene-p-xylene solution was obtained, wherein the mass ratio of polypropylene to p-xylene was 1:500; after the polyurethane sponge was ultrasonically washed with acetone for 5 minutes, it was taken out and dried and immersed in the polypropylene-p-xylene Put in the xylene solution for 5 seconds, take out the polyurethane sponge and dry it in an oven at 120° C. to obtain the above-mentioned polypropylene-modified polyurethane sponge.

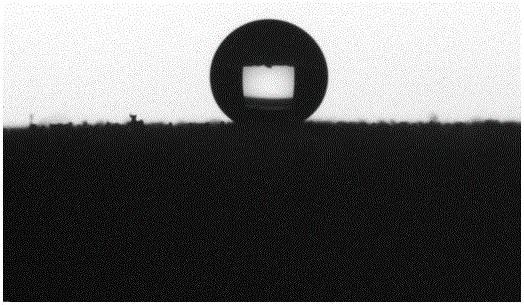

[0026] The water drop contact angle of the polypropylene-modified polyurethane sponge was measured using a contact angle measuring instrument DSA 100 (KRŰSS, Germany). First, the polypropylene-modified polyurethane sponge was placed horizontally on the contact angle measur...

Embodiment 2

[0028] Dissolve polypropylene particles (melt index: 12g / 10min) in p-xylene in an oil bath at 125°C to obtain a polypropylene-p-xylene solution, wherein the mass ratio of polypropylene to p-xylene is 1:100; After the polyurethane sponge was ultrasonically washed with acetone for 8 min, it was taken out and dried and immersed in the polypropylene-p-xylene solution for 10 s. After the polyurethane sponge was taken out, it was dried in an oven at 115°C to obtain the above polypropylene-modified Polyurethane sponge.

Embodiment 3

[0030] Under an oil bath at 127°C, dissolve polypropylene particles (melt index: 12g / 10min) in p-xylene to obtain a polypropylene-p-xylene solution, wherein the mass ratio of polypropylene to p-xylene is 1:300; After the polyurethane sponge was ultrasonically washed with acetone for 10 minutes, it was taken out and dried and immersed in the polypropylene-p-xylene solution for 15 seconds. After the polyurethane sponge was taken out, it was dried in an oven at 125°C to obtain the above-mentioned polypropylene-modified polyurethane sponge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com