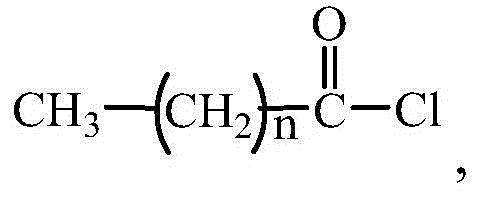

Preparation method of amphipathic comb-shaped polymer phase change energy storage material

A phase change energy storage material, comb polymer technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems affecting the properties of finished polymers, amphiphilic structure and difficult control of properties, etc. High efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

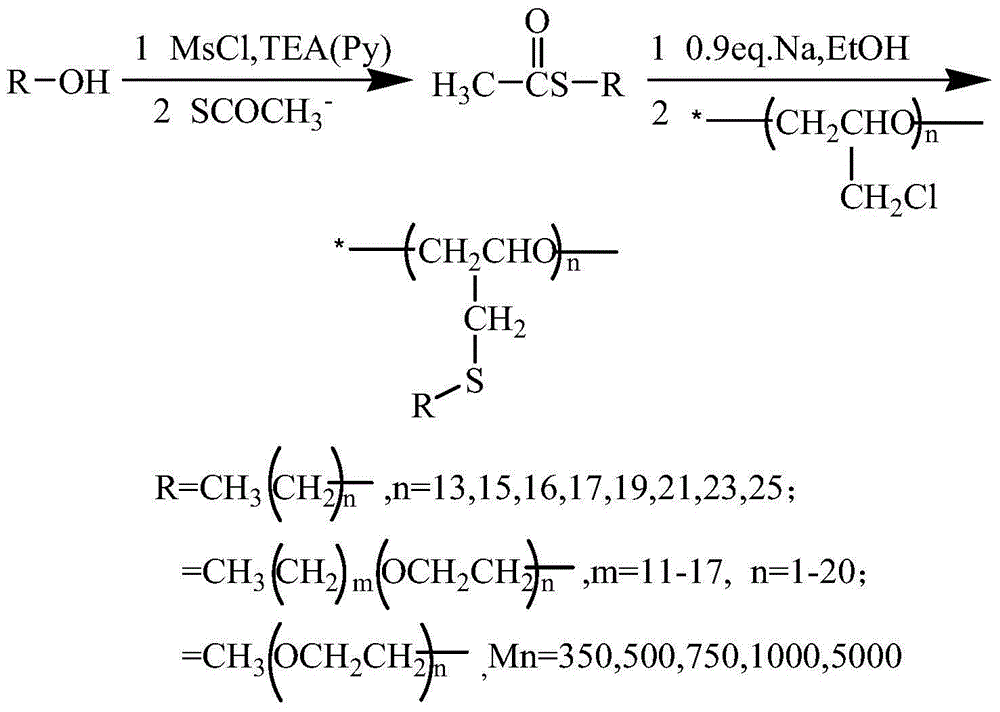

Method used

Image

Examples

Embodiment 1

[0039] 1) Dissolve poly(oxyethylene) stearyl ether (the degree of polymerization of ethylene oxide is 10) (i.e. B76) in dichloromethane (MC), and add the acid-binding acid dropwise in an ice-water bath at 0°C Catalyst triethylamine (TEA) and methanesulfonyl chloride (MsCl); The molar mass of described triethylamine is 3 times of B76, and the molar mass of methanesulfonyl chloride is 1.5 times of B76; 2 Under protection, mechanical stirring was reacted for 8 hours; after the reaction was completed, 0.5mol / L hydrochloric acid was added to the reaction product until a homogeneous solution was formed and bubbles were no longer produced, (removing unreacted TEA and MsCl), and the solution was divided into Layer, separate liquid to collect the lower layer solution, carry out rotary evaporation to the lower layer solution at room temperature, remove MC, obtain the compound with acyl active group;

[0040] 2) The compound with the acyl active group is dissolved in ethanol, and then po...

Embodiment 2

[0045] The molar ratio between B76 and MsCl in step 1) of Example 1 was adjusted to 0.5:1, and the rest was the same as in Example 1 to obtain an amphiphilic comb polymer phase-change energy storage material. The obtained amphiphilic comb polymer phase change energy storage material has an endothermic temperature of 35.6°C, a melting enthalpy of 57.9J / g, an exothermic temperature of 33.1°C, a heat-resistant temperature of 255°C, and a yield of 85%.

Embodiment 3

[0047] Adjust the molar ratio between B76 and MsCl in step 1) of Example 1 to be 1:1, and the rest are the same as in Example 1 to obtain an amphiphilic comb polymer phase-change energy storage material. The obtained amphiphilic comb polymer phase change energy storage material has an endothermic temperature of 37.0°C, a melting enthalpy of 64.2J / g, an exothermic temperature of 34.3°C, a heat-resistant temperature of 262°C, and a yield of 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| endothermic temperature | aaaaa | aaaaa |

| exothermic temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com