Method and device for treating residues of aluminum phosphide tablet fumigation agent

A treatment method and treatment device technology, applied in the direction of aluminum chloride, aluminum halide, phosphate, etc., to achieve stable treatment effects, reduce waste liquid discharge, and avoid spontaneous combustion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

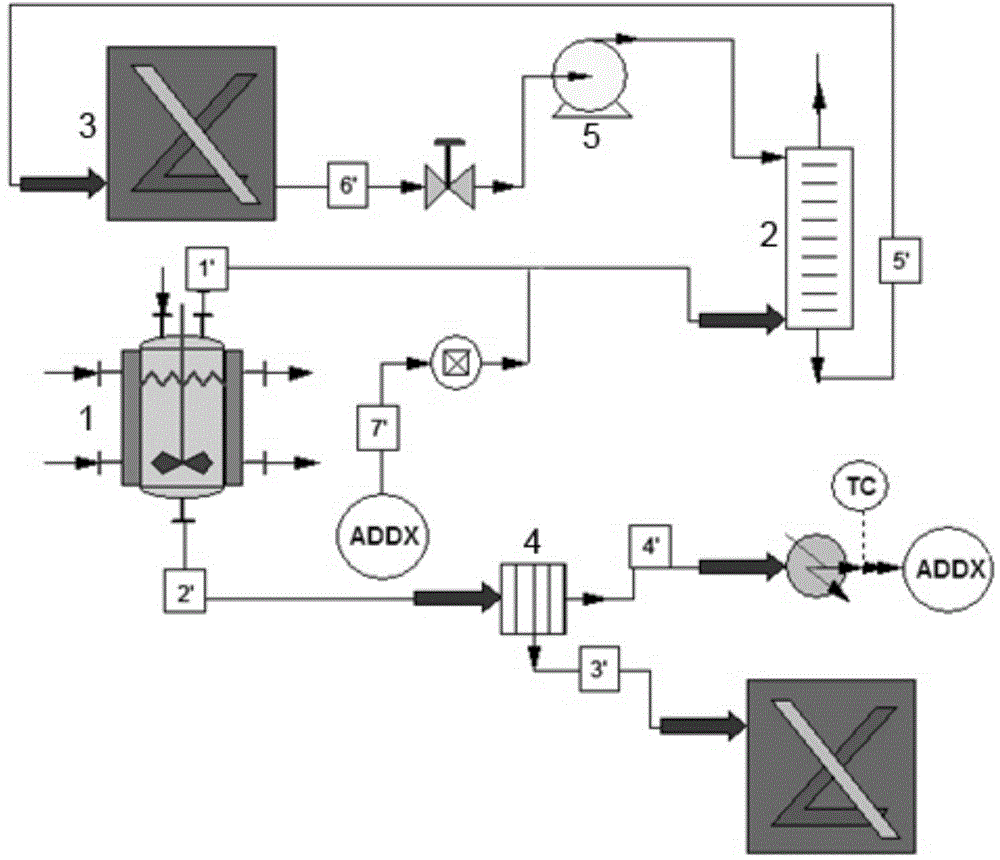

[0035] Add 1kg aluminum phosphide tablet fumigant residue to polymerization reactor 1, turn on ADDX nitrogen source (gauge pressure 1 atm or more), pass through pipeline 7', replace the air in polymerization reactor 1 three times, and purge pipeline 1' and absorption tower with nitrogen 2. Turn off the nitrogen source. In storage tank 3, be 25% sodium chlorite solution (being made up of by 25g sodium chlorite, 100ml water) 100kg, setting absorption liquid input volume is 120ml / s-1200ml / s, by metering pump 5, The sodium chlorite solution is sent to the top of the absorption tower 2 through the pipeline 6', sprayed and absorbed, and returned to the storage tank 3 through the pipeline 5' for recycling. Under the condition of airtight air, add 2000ml of water to the polymerization reactor 1 in 5 times, open the nitrogen source at the same time, the flow rate is 50ml / s, and use nitrogen as the carrier gas to carry the phosphine gas generated in the polymerization reactor 1 through ...

Embodiment 2

[0038]1kg aluminum phosphide tablet fumigant residue is added to polymerization reactor 1, open ADDX argon gas source (gauge pressure is more than 1 atm), through pipeline 7 ', replace the air in polymerization reactor 1 three times, and purge pipeline 1 ' and with argon gas Absorption tower 2, shut off the argon gas source. In storage tank 3, be 60% sodium chlorite solution (being made up of 60g sodium chlorite, 100ml water) 100kg, set absorption liquid input volume to be 120ml / s-1200ml / s, by metering pump 5, The sodium chlorite solution is sent to the top of the absorption tower 2 through the pipeline 6', sprayed and absorbed, and returned to the storage tank 3 through the pipeline 5' for recycling. Under the condition of airtight air, add 2000ml of hydrochloric acid into the polymerization reactor 1 in 5 times, open the source of argon gas at the same time, the flow rate is 50ml / s, and use argon as the carrier gas to carry the phosphine gas generated in the polymerization r...

Embodiment 3

[0041] 1kg aluminum phosphide tablet fumigant residue is added to polymerization reactor 1, open ADDX helium source (gauge pressure 1atm above), through pipeline 7 ', replace the air in polymerization reactor 1 three times, and use helium purge pipeline 1 ' and Absorption tower 2, shut off the helium source. In storage tank 3, be 75% sodium chlorite solution (promptly by the sodium chlorite of 75g, 100ml water is mixed with) 100kg, set absorption liquid input volume to be 120ml / s-1200ml / s, by metering pump 5, The sodium chlorite solution is sent to the top of the absorption tower 2 through the pipeline 6', sprayed and absorbed, and returned to the storage tank 3 through the pipeline 5' for recycling. Under the condition of airtight air, add 2000ml of water into the polymerization reactor 1 in 5 times, open the helium source at the same time, the flow rate is 50ml / s, and use helium as the carrier gas to carry the phosphine gas generated in the polymerization reactor 1 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com