Magneto-rheological finishing method of easy-deliquescence crystals

A magnetorheological polishing and deliquescent technology, which is applied in the field of magnetorheological polishing, can solve the problems of carbonyl iron powder easily embedded in the crystal surface, surface quality damage, crystal atomization, etc., to achieve easy processing and operation, low zero magnetic field viscosity, The effect of less hysteresis loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

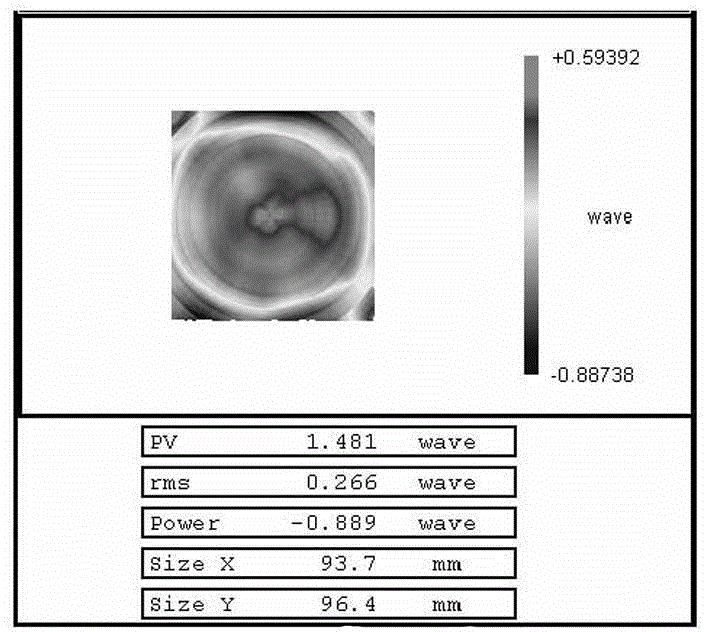

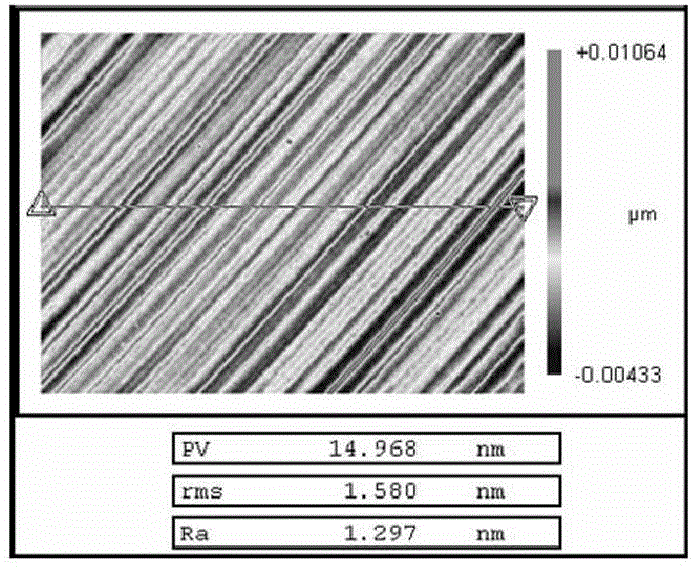

[0040] A magnetic flow of the Yichang crystal of the present invention. The processing object is a square KDP crystal with a 47mm × 47mm.λ = 632.8nm), no scratches on the surface, and the surface roughness is 1.58nm (RMS).This magnetic flowing method includes the following steps:

[0041] (1) Preparation of non -water -based magnetic flow polishing fluid, according to the quality score, the non -water -based magnetic flow polishing fluid includes 31%diurol monoclonetl ether (477g, 500ml), 59%cymbal iron powder(900g), 5%surfactant (75g), and 5%de -ion water (75g, 75ml).Among them, the viscosity of diol -diol monoclonettharson ether at 20 ° C is 6.49MPa · S; the particle size of the cymbal iron powder is mainly in the range of 1 μm to 10 μm, the average particle size is 5 μm, the net degree of Feine is greater than 97%, and the relative quality factors are greater than the quality factors greater than the factors.1.75, the effective magnetic guidance rate is greater than 3, the pyri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com