Preparation method of diffusion dialysis cation exchange membrane

A cation exchange membrane and diffusion dialysis technology, applied in the field of ion exchange membrane preparation, can solve problems such as low swelling, achieve good film-forming performance, improve stability, and promote transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, the diffusion dialysis cation exchange membrane is prepared through the following steps:

[0043] 1. Recrystallize and purify the purchased sodium styrene sulfonate (SSNa) with ethanol / water (the volume ratio of ethanol and water is 9:1). Add 30ml of methanol-water solution (volume ratio 1:1) into the polymerization tube. Continue to add 0.430ml α-ethyl bromoisobutyrate (EBiB), 0.0034g copper bromide (CuBr 2 ), 0.156mlN,N,N',N',N″-pentamethyldiethylenetriamine (PMDETA), 2gSSNa, the molar ratio of the above four substances is 20:1:50:700, mix until the solid is completely Dissolved and the liquid was clarified and homogeneous, nitrogen gas was introduced for 1 h, and oxygen was removed by bubbling.

[0044] The polymerization tube was frozen with liquid nitrogen at -198°C until all the reactants in the tube changed from liquid to solid, and then vacuumed with a vacuum pump until the vacuum degree was 0.06 Pa and kept for 3 min. Infuse nitrogen agai...

Embodiment 2

[0059]The preparation method of the cation exchange membrane of this embodiment is the same as that of Example 1, except that 1gPSSNa is mixed with 20ml 5% PVA aqueous solution, that is, the mass ratio of PSSNa and PVA is 1:1; 1.0608g (3-aminopropyl ) Triethoxysilane (A-1100) was used as a silane coupling agent instead of 1.0g TEOS to cross-link with a homogeneous solution of polyelectrolyte and PVA; the cross-linking reaction time was shortened to 2h to obtain a cation exchange membrane.

[0060] For the convenience of comparison, a similar process was adopted, but formaldehyde crosslinking was used instead of silane coupling agent crosslinking to obtain reference film 2. Wherein, the formaldehyde crosslinking process is similar to the corresponding process of the reference film 1 in Example 1.

[0061] Water content and hot water swelling performance tests were carried out on the cation exchange membrane obtained in this example. The water content test showed that the water...

Embodiment 3

[0064] The preparation method of this example is the same as that of Example 1, except that 1.1345g of γ-(2,3-glycidyloxy)propyltrimethoxysilane (KH560) is used instead of 1g of TEOS as the silane coupling agent; the crosslinking time is shortened to 20min to obtain a cation exchange membrane. The membranes were subjected to infrared, water content, thermal analysis, ion exchange capacity and DD tests.

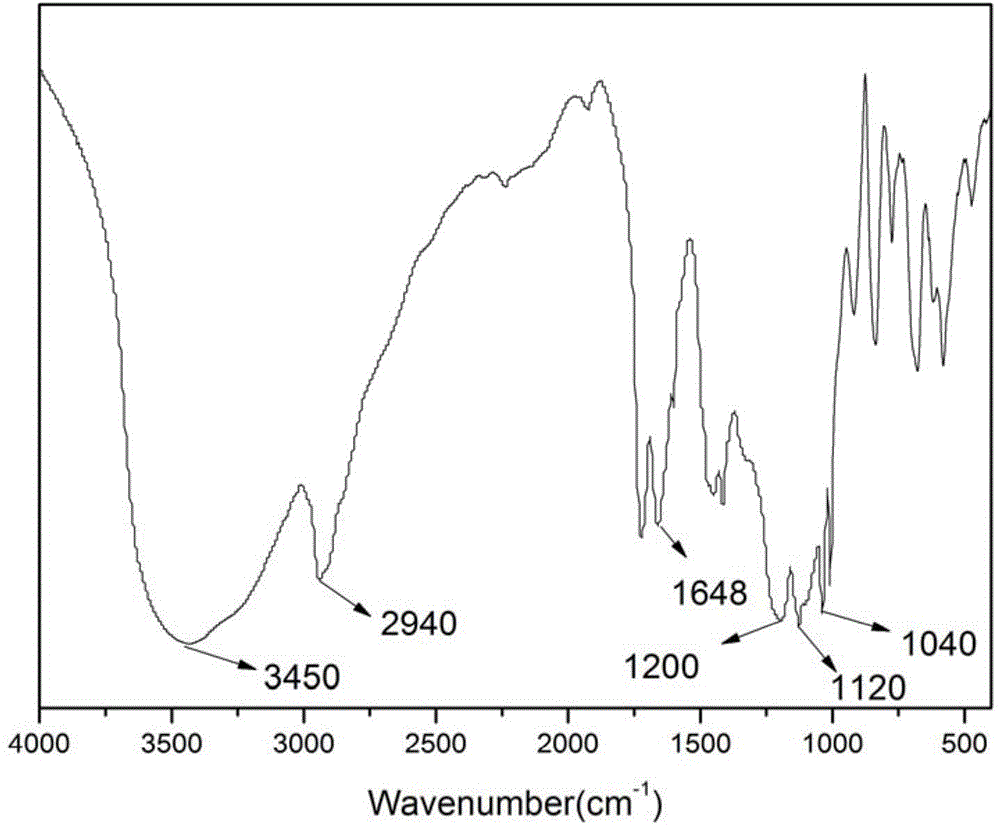

[0065] Figure 4 The infrared spectrogram of the cation-exchange membrane prepared for this embodiment, among the figure, ~3450cm -1 It is the characteristic vibration peak of -OH on PVA or -Si-OH, ~2940cm -1 for -CH 2 Absorption peak, ~1650cm -1 is-CH 3 ,-CH 2 -, = stretching vibration peak of CH- group, ~1120cm -1 It is the stretching vibration peak of -Si-O-Si-. ~1040cm -1 And ~ 1201cm -1 yes-so 3 The stretching vibration peak of Na. This indicates that PVA was successfully blended with PSSNa, and silane KH560 also played an effective cross-linking role.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com