Method for extracting volatile components from Pandanus amaryllifolius Roxb leaves

A technology for volatile components and pandanus, applied in the field of extracting volatile components of pandanus, can solve the problems of low extraction efficiency, easy decomposition of heat-sensitive substances, poor selectivity, etc., and achieve the effect of excellent extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

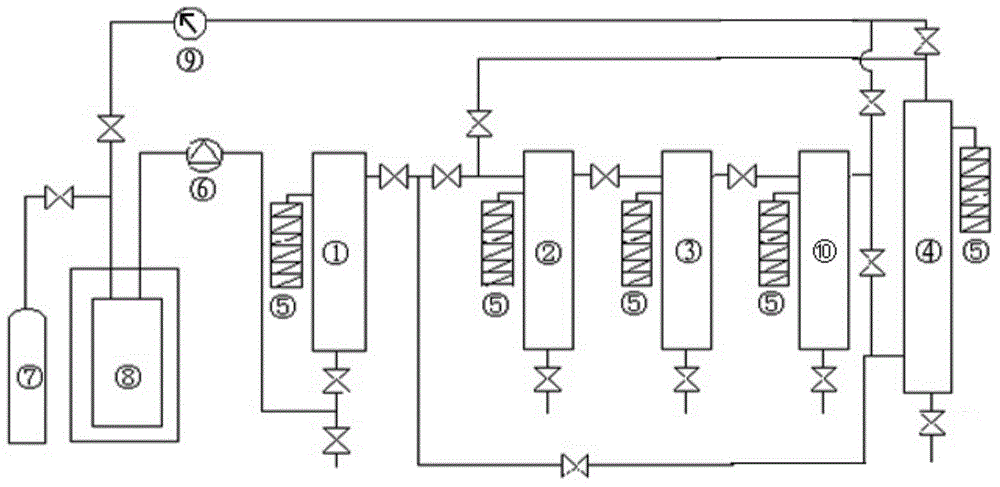

Image

Examples

Embodiment 1

[0030] (1) Grind the dried leaves of Pandanus to 20 mesh, and set aside;

[0031] (2) put step (1) pulverized Cyclopedia folium into supercritical CO 2 In the extraction kettle of the extraction device;

[0032] (3) Tighten the lid of the extraction kettle, and check whether the lid of the separation kettle and the valve are closed;

[0033] (4) Start the power supply, connect the cooling water, start the refrigerator switch, and turn on the heating switches of the extraction kettle, the separation kettle Ⅰ, the separation kettle Ⅱ and the separation kettle Ⅲ, and set the temperature of the extraction kettle to 35°C, and the separation kettle Ⅰ The temperature is 35°C, the temperature of the separation tank II is 30°C, and the temperature of the separation tank III is 30°C;

[0034] (5) When the temperature of the refrigerator drops to 5°C, and the temperature of the extraction kettle and the separation kettle at all levels reaches the set temperature and is stable, open the...

Embodiment 2

[0038] (1) Grind the dried leaves of Pandanus to 100 mesh and set aside;

[0039] (2) put step (1) pulverized Cyclopedia folium into supercritical CO 2 In the extraction kettle of the extraction device;

[0040] (3) Tighten the lid of the extraction kettle, and check whether the lid of the separation kettle and the valve are closed;

[0041] (4) Start the power supply, connect the cooling water, start the refrigerator switch, and turn on the heating switches of the extraction kettle, the separation kettle Ⅰ, the separation kettle Ⅱ and the separation kettle Ⅲ, and set the temperature of the extraction kettle to 55°C, and the separation kettle Ⅰ The temperature is 50°C, the temperature of the separation tank II is 50°C, and the temperature of the separation tank III is 50°C;

[0042] (5) When the temperature of the extraction kettle and the separation kettles at all levels reaches the set temperature and is stable, open the gas cylinder and the air source inlet valve, and fir...

Embodiment 3

[0046] (1) Grind the fresh and dried leaves of Pandanus to 60 mesh, set aside;

[0047] (2) put step (1) pulverized Cyclopedia folium into supercritical CO 2 In the extraction kettle of the extraction device;

[0048] (3) Tighten the lid of the extraction kettle, and check whether the lid of the separation kettle and the valve are closed;

[0049] (4) Start the power supply, connect the cooling water, start the refrigerator switch, and turn on the heating switches of the extraction kettle, the separation kettle Ⅰ, the separation kettle Ⅱ and the separation kettle Ⅲ, and set the temperature of the extraction kettle to 45°C, and the separation kettle Ⅰ The temperature is 45°C, the temperature of the separation kettle II is 40°C, and the temperature of the separation kettle III is 40°C;

[0050] (5) When the temperature of the extraction kettle and the separation kettles at all levels reaches the set temperature and is stable, open the gas cylinder and the air source inlet valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com