A kind of preparation method and application of polymer electrolyte material for lithium battery

A technology of electrolyte materials and polymers, applied in the direction of lithium batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve problems such as electrical conductivity and mechanical properties that cannot be taken into account, safety hazards, etc., to achieve improved safety performance, high safety performance, The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First, polyethylene glycol (MW=300) is added to a four-necked bottle with a thermometer, a stirrer, a feeding tube, and a condensing tube, and 2 drops of catalyst are added dropwise, and IPDI is added dropwise, wherein NCO:OH (molar ratio) is 1.25:1. After reacting at 25°C for 4 hours, add ethylene glycol monoallyl ether, wherein the remaining NCO:OH (molar ratio) is 1:1.2, and the temperature is controlled at 65°C. During the reaction process, DEC was continuously added to adjust the temperature of the system, and the conversion rate of NCO was measured. When the conversion rate reached 99%, the reaction was stopped to obtain a prepolymer. The molecular weight of the prepolymer is 580,000, and the dispersion coefficient is 1.02.

[0033] Accurately weigh a certain amount of prepolymer and place it in a sample bottle, add 20% by weight of active monomer PETA, add 0.1% by weight of photoinitiator 4265, stir well, apply it on a release paper, and place it in a UV curing d...

Embodiment 2

[0035] Polyethylene glycol (M W =2000) into a four-neck flask equipped with a thermometer, agitator, feeding tube, and condenser, dropwise add 2 drops of catalyst, and dropwise add IPDI, wherein NCO:OH (molar ratio) is 3:1. React at 50°C for 4h Finally, add ethylene glycol monoallyl ether, wherein the remaining NCO:OH (molar ratio) is 1:1.2, and the temperature is controlled at 85°C. During the reaction process, DMC was continuously added to adjust the temperature of the system, and the conversion rate of NCO was measured. When the conversion rate reached 99%, the reaction was stopped to obtain a prepolymer. The molecular weight of the prepolymer is 30,000, and the dispersion coefficient is 1.33.

[0036] Accurately weigh a certain amount of prepolymer and place it in a sample bottle, add 0.5% by weight of active monomer PETA, add 12% by weight of initiator 4265, stir well, apply it on a release paper, and place it under a UV curing device Irradiate for 90 seconds. After be...

Embodiment 3

[0038] Polyethylene glycol (MW=2000), amino-terminated polysiloxane (M W About 1700) into a four-neck flask with a thermometer, agitator, feeding tube, and condenser, drop 2 drops of catalyst, drop IPDI, where NCO:OH (molar ratio) is 3:1. 50 ° C reaction After 4h, add ethylene glycol monoallyl ether, wherein the remaining NCO:OH (molar ratio) is 1:1.2, and the temperature is controlled at 75°C. During the reaction process, the mixed solvent (DMC:DEC:EC=1:1:1) was continuously added to adjust the temperature of the system, and the conversion rate of NCO was measured. When the conversion rate reached 99%, the reaction was stopped to obtain a prepolymer. The molecular weight of the prepolymer is 30,000, and the dispersion coefficient is 1.33.

[0039] Accurately weigh a certain amount of prepolymer and place it in a sample bottle, add 20% by weight of active monomer PETA, 12% by weight of initiator 4265 and 0.5% by weight of hexafluorobutyl acrylate, stir well, and apply on rele...

PUM

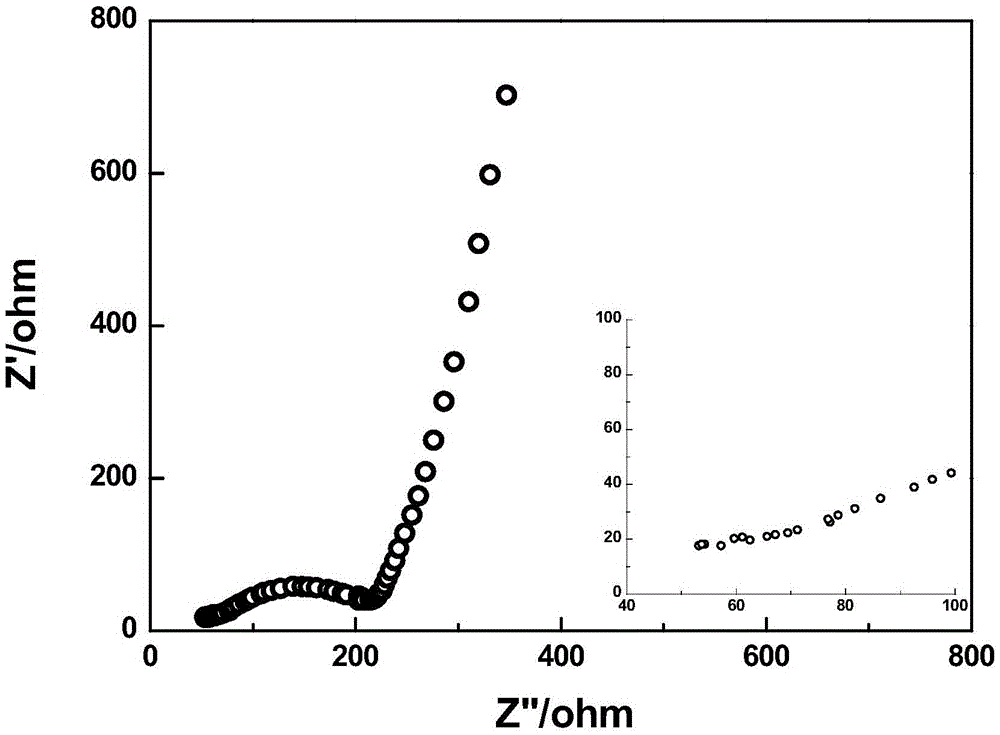

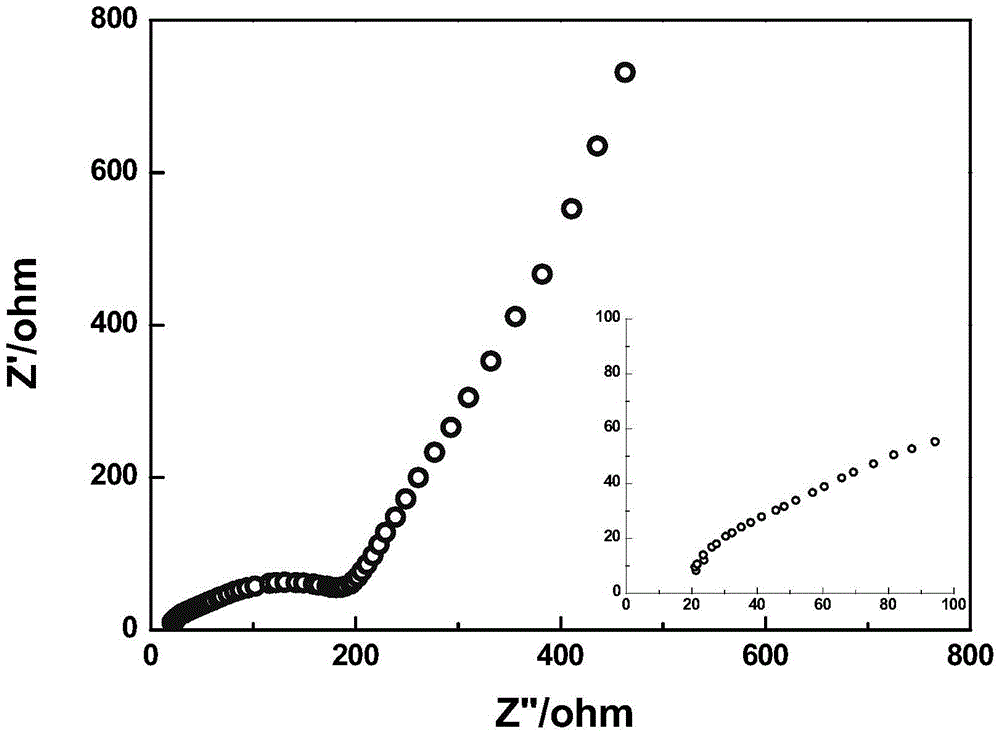

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com