High-power kick type temperature controller and assembly method thereof

A jump-type temperature controller and assembly method technology, applied in the direction of electrical components, electrical switches, circuits, etc., can solve the problems of small conductive cross-sectional area, poor contact, etc., achieve reliable operation, increase service life, and improve reliable electrical connection sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

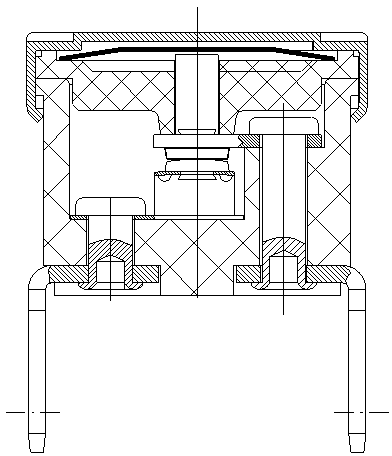

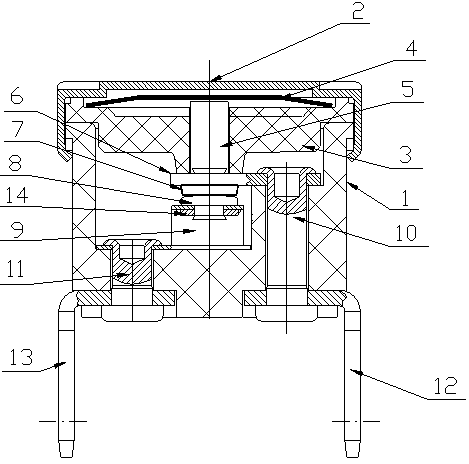

[0022] Such as image 3 , 4 , 5, the jump-type thermostat of this embodiment includes a housing 1, a cover 2, a guide frame 3, a bimetal disc 4, an action rod 5, a fixed plate 6, and a static contact 7. The static contact piece, the movable contact assembly composed of the movable contact 8 and the shrapnel 9, the first rivet 10, the second rivet 11, the first terminal 12, the second terminal 13, the action rod 5 is installed on the guide frame 3, the end of the action rod 5 faces the shrapnel 9; the bimetal disc 4 is located between the cover 2 and the action rod 5; On the inner and outer sides of the housing 1 , the elastic piece 9 and the second connection terminal 13 in the movable contact assembly are pressed against the inner and outer sides of the housing 1 by the second rivets 11 .

[0023] The above-mentioned assembly method of the jump-type thermostat includes the steps of assembling the movable contact assembly, installing the static contact piece and the first te...

Embodiment 2

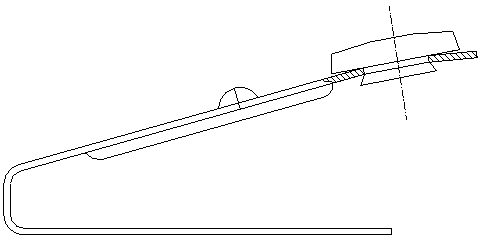

[0028] Such as Image 6 As shown, the shrapnel 9 in this embodiment is provided with a nail hole, the handle of the movable contact 8 is a hollow handle, and the handle of the movable contact 8 is riveted with the shrapnel 9 after passing through the nail hole. The shank of 8 forms an annular pressing surface that is pressed against the shrapnel 9 .

[0029] The above steps of assembling the moving contact assembly are as follows: use the moving contact 8 with a hollow handle, pass the handle of the moving contact 8 through the nail hole and rivet it with the shrapnel 9, so that the handle of the moving contact 8 expands and flangs, and then connects with the The nail hole of the elastic piece 9 is interference fit, and makes the handle of the movable contact 8 form an annular pressing surface pressed against the elastic piece 9 .

[0030] Other structures and assembly methods of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0031] ...

Embodiment 3

[0033] Such as Figure 7 As shown, the shrapnel 9 in this embodiment is provided with a nail hole, and the handle of the movable contact 8 is provided with an axial groove, and the handle of the movable contact 8 passes through the nail hole and is riveted with the shrapnel 9. The flanging of the handle of the contact 8 forms a pressing surface that is pressed against the elastic piece 9 .

[0034] The above steps of assembling the moving contact assembly are as follows: use the moving contact 8 with an axial groove on the handle, pass the handle of the moving contact 8 through the nail hole and rivet it with the shrapnel 9, so that the handle of the moving contact 8 expands Afterwards, the two sides are separated, and are interference-fitted with the nail holes of the elastic piece 9 , and the handle of the movable contact 8 forms a pressing surface pressed against the elastic piece 9 .

[0035] Other structures and assembly methods of this embodiment are the same as those o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com