Transformer oil-paper insulation electricity-heating unite ageing test device

A technology for transformer oil and aging experiments, applied in the field of transformers, can solve the problems of inconvenient operation and low reliability, and achieve the effects of simple operation, accelerated aging process, and enhanced circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

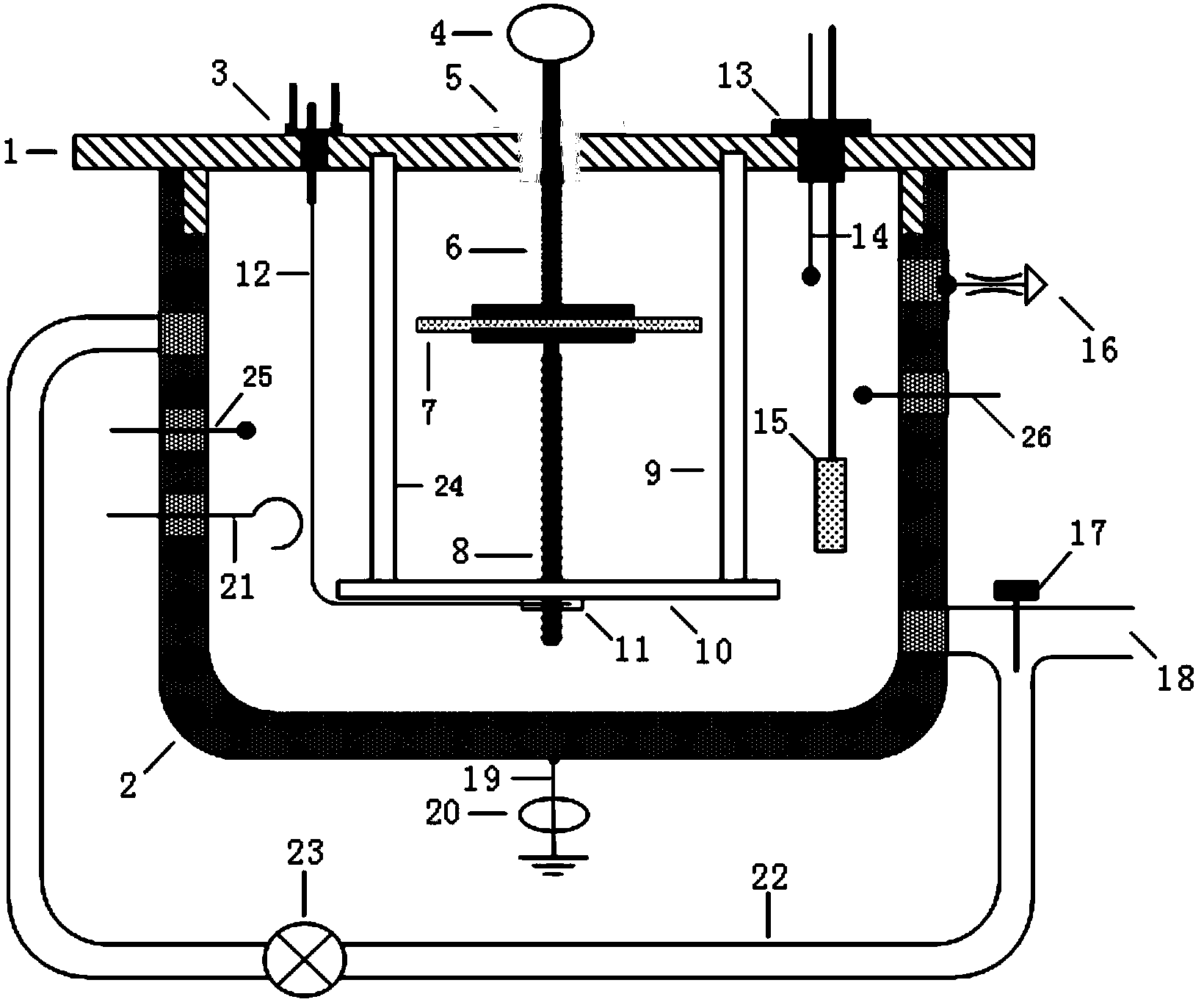

[0042] like figure 1 As shown, the experimental device of the present invention includes a sealed cavity, a test device, a heating device, a partial discharge detection device, an oil inlet and an air inlet.

[0043] The sealed cavity includes a metal upper cover plate 1 and a metal lower shielding shell 2, the metal lower shielding shell 2 is an open box structure, the metal upper cover plate 1 is installed at the opening of the metal lower shielding shell, the metal upper cover plate 1 and the metal lower shielding shell The interface of the metal lower shielding shell 2 is provided with positioning grooves that cooperate with each other to prevent sliding. The metal upper cover plate 1 is equipped with a BNC connector 3 for leading out the low-voltage electrode 8 , a high-voltage flange 5 for leading out the high-voltage electrode 6 , and a heating penetrating piece 13 for fixing the heating device.

[0044] The test device is located in the sealed cavity and fixed with th...

Embodiment 2

[0050] This embodiment is provided with an oil delivery pipeline 22 and an electric pump 23 on the basis of the first embodiment, the electric pump 23 is arranged on the oil delivery pipeline 22, and the oil inlet 18 is a pipeline arranged on the metal lower shielding shell 2 port, the oil intake port 18 communicates with the metal lower shielding shell 2 through the pipeline where it is located, one end of the oil delivery pipeline 22 communicates with the metal lower shielding shell 2, and the other end of the oil delivery pipeline 22 is arranged at the place where the oil intake port is located. On the pipeline, it is connected with the oil intake port 18 and the metal lower shielding shell 2. An oil intake control valve 17 is arranged on the pipeline where the oil intake port 18 is located. The oil intake control valve 17 is a three-way valve. Through the oil intake control valve 17 Control the passage of the oil pipeline 22 .

[0051] At the beginning of the experiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com