Method and device for in-situ simultaneous testing of fracture toughness and residual stress of brittle materials

A technology of residual stress and fracture toughness, which is applied in the direction of testing the hardness of materials and testing the strength of materials by applying stable tension/pressure, which can solve the problems of low accuracy of experimental testing, cumbersome analysis, and lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

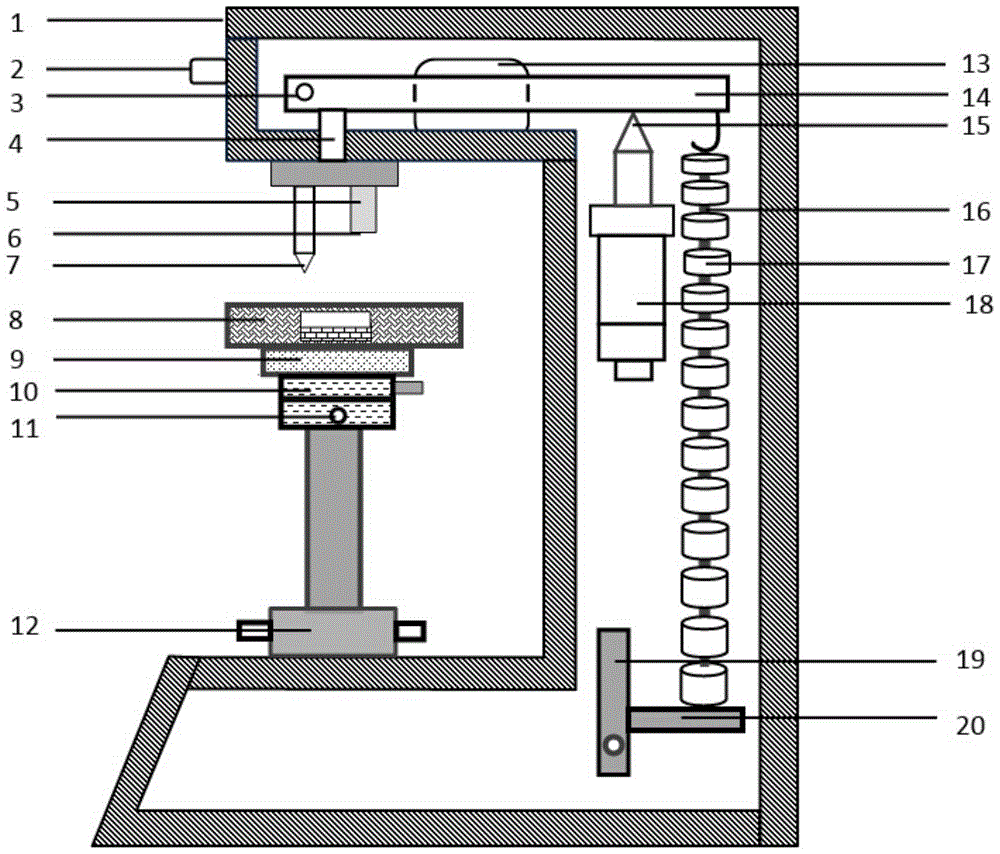

Image

Examples

Embodiment 1

[0093] Using the existing indentation method and the method of the present invention to test the interface fracture toughness and residual stress of the plasma sprayed thermal barrier coating sample at room temperature, the steps of the specific examples are as follows:

[0094] The first step is to prepare the sample. The thermal barrier coating ceramic material is sprayed on the high-temperature nickel alloy substrate by using the plasma spraying process. The composition of the coating system of the sample is: the transition layer material is NiCrAlY alloy, and its thickness is about 150 μm; the ceramic powder material is 8wt% Y 2 o 3 -ZrO 2 , The thickness of the sprayed ceramic layer is about 350 μm. Perform fine metallographic treatment on the sample, including rough grinding, fine grinding, polishing, removal of work hardening, ultrasonic cleaning and other procedures, so that the surface of the tested sample is as smooth as possible without scratches and meets the te...

Embodiment 2

[0106] Using the device of the present invention to test the interface fracture toughness and residual stress of the plasma sprayed thermal barrier coating sample at 1000°C, the steps of the specific examples are as follows:

[0107] The first step is to prepare the sample. The thermal barrier coating ceramic material is sprayed on the high-temperature nickel alloy substrate by using the plasma spraying process. The composition of the coating system of the sample is: the transition layer material is NiCrAlY alloy, and its thickness is about 150 μm; the ceramic powder material is 8wt% Y 2 o 3 -ZrO 2 , The thickness of the sprayed ceramic layer is about 350 μm. Perform fine metallographic treatment on the sample, including rough grinding, fine grinding, polishing, removal of work hardening, ultrasonic cleaning and other procedures, so that the surface of the tested sample is as smooth as possible without scratches and meets the test requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com