Method for determining content of Ir in gold jewelry by microwave digestion ICP-AES (Inductively Coupled Plasma-Atomic Emission Spectrometry)

An ICP-AES, microwave digestion technology, applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve problems such as insoluble, overcome doping problems, reduce human errors, and use less reagents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Experimental part

[0027] Instruments and reagents

[0028] Italian MILESTONE ETHOSA microwave digestion instrument; American Thermo IRIS Intrepid II inductively coupled plasma emission spectrometer; American Denver T-214 electronic balance. HNO 3 (excellent pure); HCl (excellent pure); H 2 o 2 (Excellent grade pure); Experimental water is secondary deionized water; Ir standard stock solution series: 1000ppm, Beijing Nanke Analytical Instrument Co., Ltd.; The sample used is iridium-doped gold jewelry, purchased from a certain market in Jinan.

[0029] Microwave Digester Working Conditions

[0030] This study adopts a step-by-step digestion method to overcome the defects of small volume and low pressure of the sample digestion tank, to ensure the complete digestion of the sample, and to avoid the use of hydrofluoric acid used in previous related studies, so that subsequent samples can be directly injected .

[0031] The first step of digestion process: Take the de...

Embodiment 2

[0062] In 1.2, the first step of digestion process: take a debris sample, accurately take about 0.0500g,

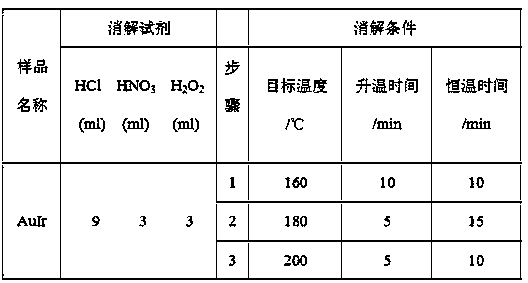

[0063] Table 1 Working conditions of microwave digestion samples in the first step

[0064]

[0065] Table 2 Working conditions of microwave digestion samples in the second step

[0066]

[0067] 2.2 During the drawing of the standard curve, draw the standard stock solution of the Ir element and dilute it with 5% nitric acid to form a standard series of 0.0, 1.0, 2.0, 5.0 mg / L (the above concentrations can be adjusted as required) Others are the same as in Example 1 same.

Embodiment 3

[0069] In 1.2, the first step of digestion process: take a debris sample, accurately take about 0.1500g,

[0070] Table 1 Working conditions of microwave digestion samples in the first step

[0071]

[0072] Table 2 Working conditions of microwave digestion samples in the second step

[0073]

[0074] 2.2 During the drawing of the standard curve, draw the standard stock solution of the Ir element and dilute it with 5% nitric acid to form a standard series of 0.0, 1.0, 2.0, 5.0 mg / L (the above concentrations can be adjusted as required) Others are the same as in Example 1 same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com