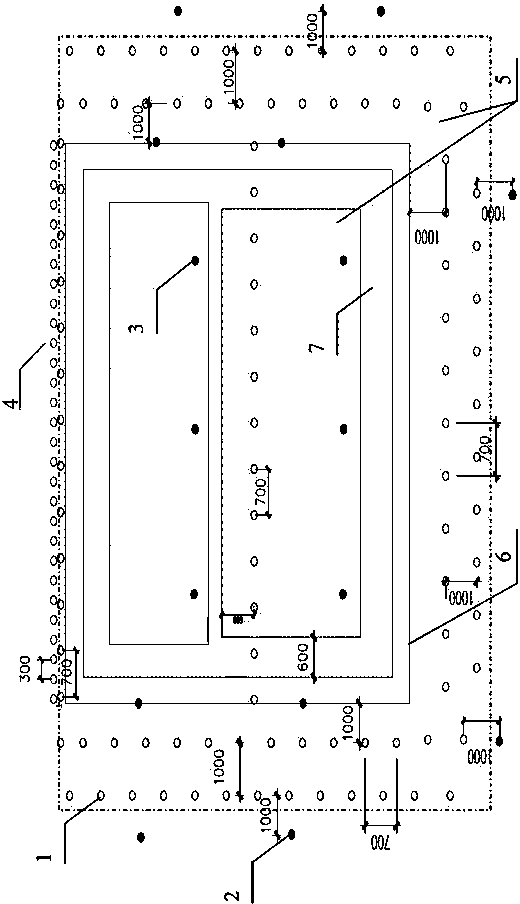

Full-sectional grouting, rectangular horizontal freezing and pipe roof combined reinforcing structure and method

A full-section grouting and joint reinforcement technology, which is applied in earthwork drilling, shaft lining, tunnel lining, etc., can solve the problems of large excavation section, security, and difficult stability of the working face, and achieves convenient construction and obvious environmental protection benefits , to ensure the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] Nanjing Metro Mengdu Street Station is the sixth station of Line 10. The station is located on Leshan Road between Songhuajiang West Street and Mengdu Street. The terrain around the station site is flat, and the ground elevation is about 6.5-8.0m. The red line width of Leshan Road is 40m, that of Mengdu Street is 65m, and that of Songhuajiangxi Street Road is 24m. Traffic is currently light. The south side of the station is the Austrian-Song open-cut section, and the north side is the Song-Green shield section. The total building area of the station is 14924.19㎡, of which the main building area is 10758.42㎡ and the auxiliary building area is 4165.77㎡. There are 5 entrances and exits in this station (Channel No. 1 is divided into two ground entrances and exits 1A and 1B, of which No. 1A entrance and exit crosses Mengdu Street and also serves as a cross-street passage), 1 barrier-free entrance, 1 fire evacuation exit and 3 Group air pavilion (8 air outlets). The tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com