A base troweling material that prevents cracking of interior decoration

A decorative and base technology, applied in the field of troweling materials, can solve the problems of poor anti-cracking effect of anti-cracking materials and long-lasting effect, and achieve wide tolerance, prevent decorative cracking, and thin coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

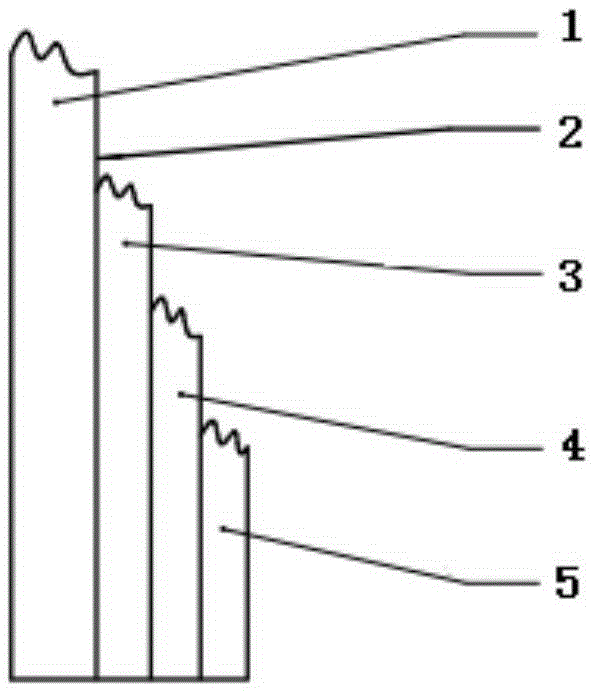

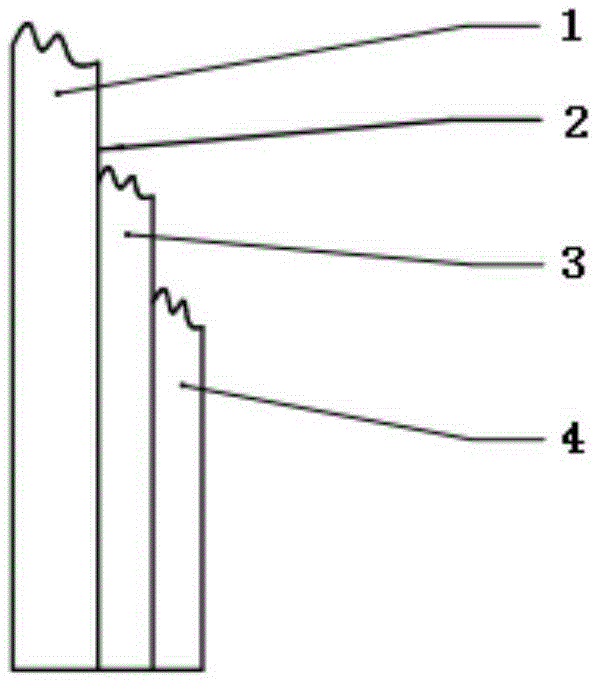

Image

Examples

specific Embodiment approach 1

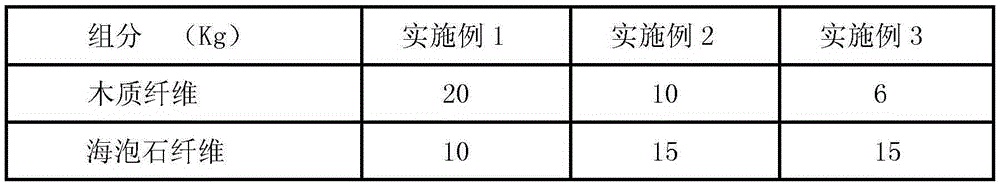

[0055] Specific Embodiment 1: In this embodiment, the components and parts by weight of the basic smoothing material that can prevent interior decorative cracking include 10-30 parts of buffer reinforcing fiber, 35-50 parts of lightweight heat insulation material, 15-35 parts of Inorganic mineral humidity-conditioning material, 3-15 parts of flexible elastic material, 10-25 parts of thickening resistance material, 10-35 parts of redispersible latex powder, 2-15 parts of antibacterial and antifungal agent, 5-20 parts of anti-caking agent , 5 to 15 parts of reinforcing agent.

[0056] The buffer reinforcing fiber is one or a mixture of two or more of wood fiber, sepiolite fiber and aluminum silicate fiber in any ratio; preferably wood fiber and sepiolite fiber.

[0057] The lightweight thermal insulation material is one of lightweight floating beads and hydrophobic perlite or a mixture of the two in any ratio; preferably lightweight floating beads.

[0058] The inorganic minera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com