Fe-Al-Nb alloy coating and preparation method thereof

A fe-al-nb, alloy coating technology, applied in the direction of metal material coating process, coating, metal layered products, etc., to reduce room temperature brittleness, solve cracking or even peeling, and save rare metal element Nb.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

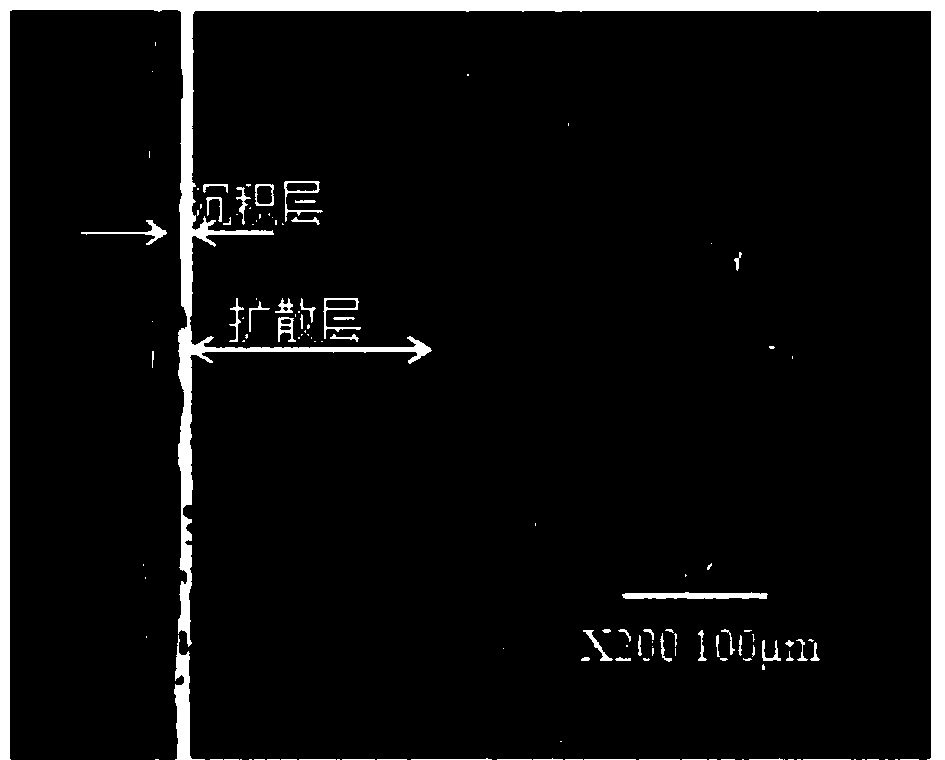

[0043] A kind of Fe-Al-Nb alloy coating of the present invention, Fe-Al-Nb alloy coating is made up of base layer, deposit layer and diffusion layer three parts; Described base layer is common carbon steel material, and described deposit layer is made of Nb99.5wt%, the rest consists of AlNb 2 , Fe 7 Nb 6 , Fe 2 Al 5 and Fe 3 Al composition;

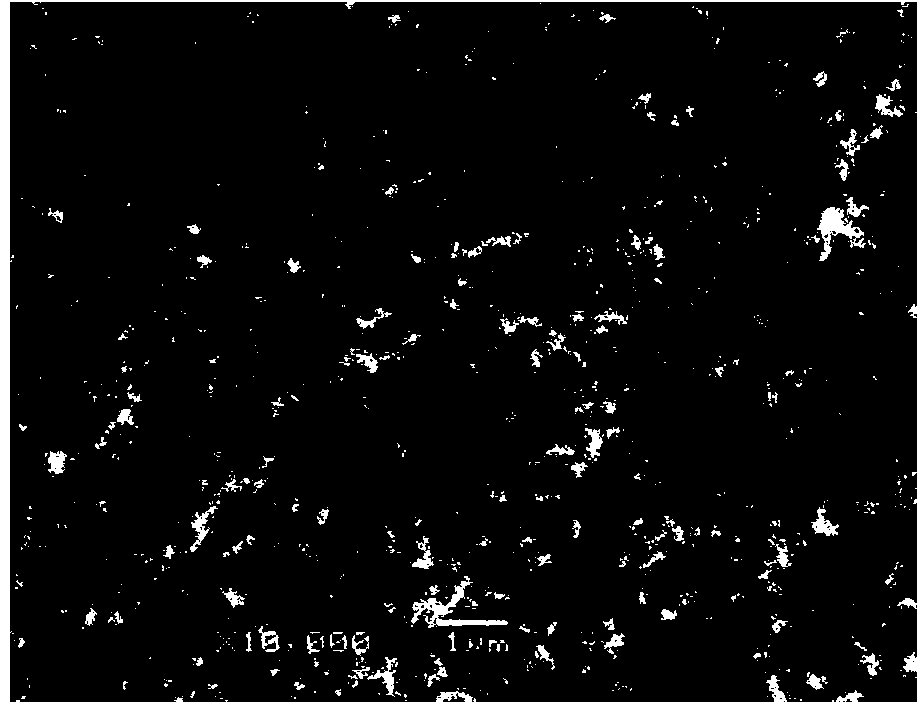

[0044] Such as figure 1 with figure 2 As shown, the surface of the Fe-Al-Nb alloy coating prepared by the present invention is smooth and bright, the microstructure is distributed in a cellular form, and the small polygonal particles are in an island-like three-dimensional shape; the coating thickness is 200 μm,

[0045] Such as image 3 As shown, the deposited layer is mainly Nb, and Nb is 99.5wt%;

[0046] Such as Figure 4 As shown, the remaining 0.5wt% of the deposited layer consists of AlNb 2 , Fe 7 Nb 6 , Fe 2 Al 5 and Fe 3 Al cemented carbide phase composition, significantly improving its surface hardness;

[0047...

Embodiment 2

[0072] The preparation method of Fe-Al-Nb alloy coating of the present invention comprises the steps:

[0073] Hot-dip aluminum plating + vacuum diffusion annealing process:

[0074] (1) Cleaning: prepare the Q235 plate; degreasing: place the above Q235 in an acetone solution for ultrasonic cleaning for 5 minutes to remove oil, and then use distilled water to clean the remaining acetone solution on the surface; % dilute hydrochloric acid for 20 minutes to remove rust, and then use distilled water to clean the remaining hydrochloric acid solution on the surface of the material;

[0075] (2) Flux plating: place Q235 in a flux with a temperature of 70°C, take out the sample after 15 minutes and quickly dry the surface of the sample;

[0076] (3) Melting aluminum: adding industrial pure aluminum ingots into graphite crucibles and heating to 800°C to become a liquid, and then removing the oxides covering the surface of the molten aluminum, and evenly spreading the covering agent o...

Embodiment 3

[0090] The preparation method of Fe-Al-Nb alloy coating of the present invention comprises the steps:

[0091] Hot-dip aluminum plating + vacuum diffusion annealing process:

[0092] (1) Cleaning: prepare 45 steel plates; degreasing: put the above 45 steel in acetone solution for ultrasonic cleaning for 8 minutes to remove oil, and then use distilled water to clean the remaining acetone solution on the surface; derusting: place in concentration after degreasing Soak in 8% dilute hydrochloric acid for 15 minutes to remove rust, and then use distilled water to clean the remaining hydrochloric acid solution on the surface of the material;

[0093] (2) Flux plating: place 45 steel in a flux with a temperature of 75°C, take out the sample after 13 minutes and quickly dry the surface of the sample;

[0094] (3) Melting aluminum: add industrial pure aluminum ingots into graphite crucibles and heat to 775°C to become liquid, then remove the oxides covering the surface of the molten a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com