Method and device for electrochemical automatic monitoring of COD combined with water heavy metal ions

A heavy metal ion, automatic monitoring technology, applied in the direction of material electrochemical variables, etc., can solve the problems of not being able to detect the concentration of COD and heavy metal ions at the same time, without considering the influence of temperature, etc., to improve adaptability and test stability, and ensure long-term stability Comparability and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

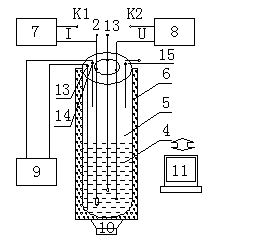

Image

Examples

Embodiment 1

[0028] The measuring heads of the working electrode 1 and the auxiliary electrode 2 in the three-electrode system are made of highly doped silicon-based BDD material, the thickness of the silicon wafer is 2 mm, and the thickness of the BDD coating is 20 μm. The working electrode measuring head is round with a diameter of 2mm. The auxiliary electrode measuring head is also circular with a diameter of 10mm. Weld copper wire on the surface of the silicon wafer and package it with a glass tube with an outer diameter of 3mm. The working electrode 1 and the auxiliary electrode 2 are placed relatively parallel with a distance of 10mm; the reference electrode is a saturated calomel electrode, and the measuring head is close to the working electrode with a distance of 1mm. The three electrodes are fixed on the fixed terminals on the top of the integrated electrolytic cell 12 and sealed. The lower end of the measuring head of the auxiliary electrode 2 is 10 mm away from the bottom of t...

Embodiment 2

[0033] Based on the device of Example 1, the present invention can be used for automatic monitoring of the COD and lead ion concentration of lead-acid battery manufacturing wastewater.

[0034] At the beginning of the automatic measurement and sequencing of the device, the electrodes and the inner wall of the integrated electrolytic cell are cleaned first. The sample inlet and discharge device 9 injects 15 mL of distilled water into the integrated electrolytic cell 12, and then applies a positive voltage of 3.0V to the auxiliary electrode (2), while setting the power of the ultrasonic device 10 to 8W for 5 minutes to discharge the distilled water; Start the EOD procedure. The sampling device 9 pumps 10mL, 1mol / L sodium sulfate solution and 5mL waste water, applies a voltage of 2.8V to the auxiliary electrode 2 for 10 minutes, and the current measurement module 7 records the current under the control of the instrument control system 11 The change and its value. During the 10 min...

Embodiment 3

[0039] Based on the device of Embodiment 1 of the present invention, the present invention can also be used for automatic monitoring of the COD and mercury ion concentration of surface water.

[0040] The device starts to measure and sequence automatically, and first clean the electrodes. The sampling device 9 injects 15 mL of distilled water into the integrated electrolytic cell, and then applies a 3.0V voltage to the auxiliary electrode (2), while setting the power of the ultrasonic device 10 to 8W for 5 minutes, and then discharges the distilled water; then, start EOD program. The sampling device 9 pumps 5mL, 1mol / L sodium nitrate, sodium chloride mixed solution and 10mL waste water, and applies a 2.1V voltage to the auxiliary electrode 2 for 10 minutes. The current measurement module 7 is in the instrument control system 11 Record current changes and their values throughout the entire process under control. During the 10 minutes of applying a 2.1V voltage to the auxiliary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com