Method for measuring content of free magnesium oxide in steel slag

A magnesium oxide, free state technology, applied in the field of environmental protection, energy saving and emission reduction, and metallurgy, can solve problems such as brick and product damage, engineering ground and wall cracking, road cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Mg(OH) 2 →MgO+H 2 O↑

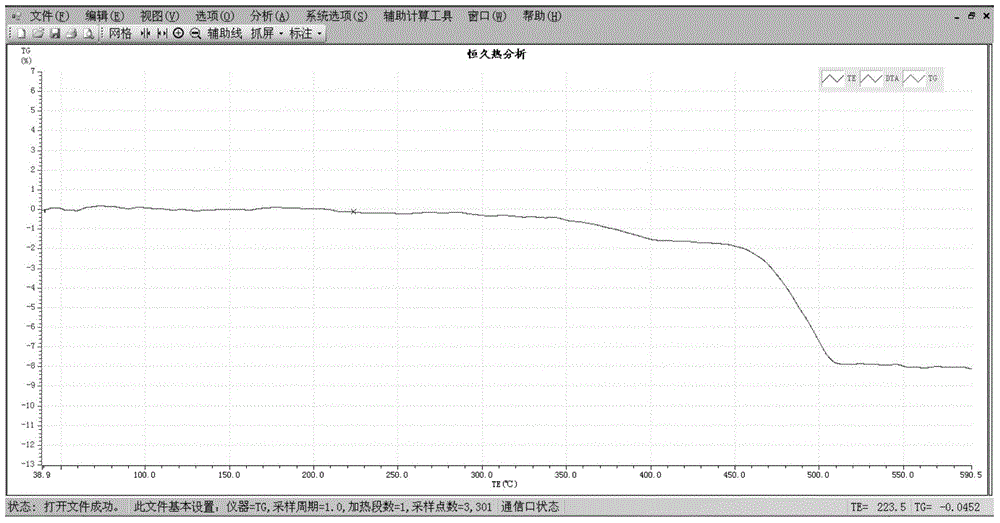

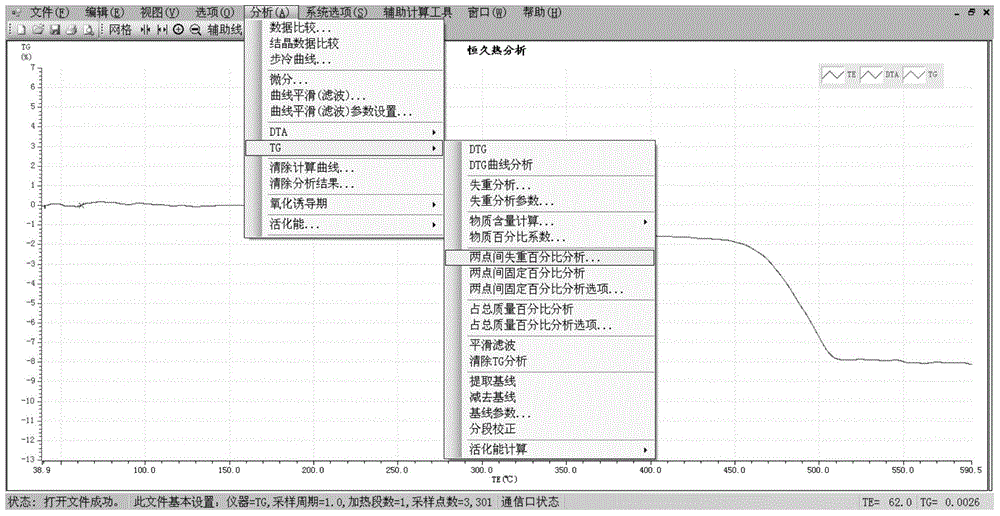

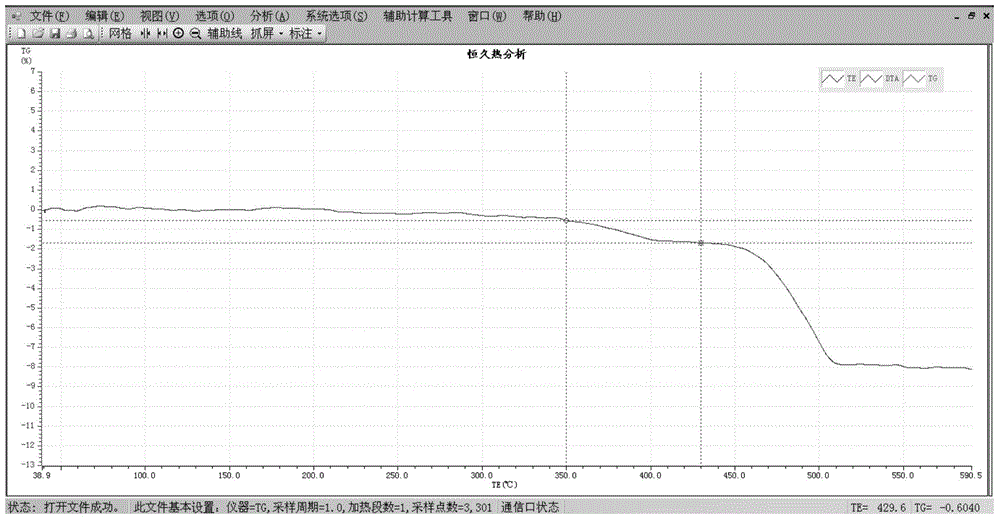

[0033] The weight loss percentage (mass loss percentage) is the weight loss percentage of water in the above formula, and the weight loss temperature range is: 350°C-430°C. According to the weight loss percentage of water, the weight loss after steaming, drying and grinding is calculated. The weight percentage difference of magnesium hydroxide in the steel slag powder and the steel slag powder before pressure steaming is C×3.2222, and then the weight percent of free magnesium oxide in the steel slag is calculated W=C×3.2222×0.6896;

[0034] In the formula: W—weight percentage of free magnesium oxide in steel slag, %;

[0035] C—the weight loss percentage difference, %; C=C 后 --C 前 ;

[0036] 3.2222—Mg(OH) 2 with H 2 The ratio of the molecular weight of O;

[0037] 0.6896—MgO and Mg(OH) 2 The ratio of the molecular weight.

[0038] Assay C 前 =0.05%, C 后 =1.14%, then C=1.14%-0.05 =1.09%

[0039] Then the weight percentage of free mag...

Embodiment 2

[0044] Mg(OH) 2 →MgO+H 2 O↑

[0045] The weight loss percentage (mass loss percentage) is the weight loss percentage of water in the above formula, and the weight loss temperature range is: 350°C-430°C. According to the weight loss percentage of water, the weight loss after steaming, drying and grinding is calculated. The weight percentage difference of magnesium hydroxide in the steel slag powder and the steel slag powder before pressure steaming is C×3.2222, and then the weight percent of free magnesium oxide in the steel slag is calculated W=C×3.2222×0.6896;

[0046] In the formula: W—weight percentage of free magnesium oxide in steel slag, %;

[0047] C—the weight loss percentage difference, %; C=C 后 --C 前 ;

[0048] 3.2222—Mg(OH) 2 with H 2 The ratio of the molecular weight of O;

[0049] 0.6896—MgO and Mg(OH) 2 The ratio of the molecular weight.

[0050] Assay C 前 =0%, C 后 =1.05%, then C=1.05%

[0051] The weight percentage of free magnesium oxide in the st...

Embodiment 3

[0054] In the formula: W—weight percentage of free magnesium oxide in steel slag, %;

[0055] C—the weight loss percentage difference, %; C=C 后 --C 前 ;

[0056] 3.2222—Mg(OH) 2 with H 2 The ratio of the molecular weight of O;

[0057] 0.6896—MgO and Mg(OH) 2 The ratio of the molecular weight.

[0058] Among them, the determination of C 前 =0%, C 后 =2.15%, then c=2.15%

[0059] The weight percentage of free magnesium oxide in steel slag is W=2.15%×3.2222×0.6896=4.80%. Since there is no free magnesium oxide after the measurement in Example 2, the electric furnace slag mixed with pure MgO measured by thermogravimetric analyzer Y The free magnesium oxide contained in it is specifically 52.5g×4.80%=2.52g, which is roughly equal to the content of 2.5g of pure MgO mixed in. Therefore, the determination method is feasible and the result is accurate.

[0060] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com