Z-shaped steel pipe-steel framework recycled concrete combined pillar

A technology of recycled concrete and composite columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of high water absorption, poor strength, poor shrinkage performance and durability, and limit the scope of use, so as to improve the bearing capacity and stress performance, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

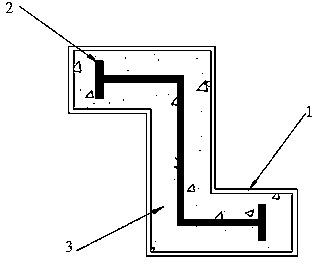

[0017] The present invention can be implemented in general concrete component factories. It is composed of steel frame, steel pipe and recycled concrete. The steel frame 2 is welded by steel plates. The recycled concrete is located inside the steel pipe. The concrete wraps the steel frame. The bone 2 is welded into a Z shape, the steel frame 2 is located in the center of the Z-shaped steel pipe 1, and is coaxial with the Z-shaped steel pipe, the outside of the steel frame 1 is recycled concrete, and the inner steel frame and steel pipe are fixed together with the bottom plate by welding or bolting. The steel frame 1 is a Z shape welded by two T shapes and a straight steel plate. The center of the Z-shaped steel pipe 1 refers to the center of the upper rectangular part of the limb, the steel frame 2 is arranged in a T shape and a straight line, and the bottom ends of the vertical columns of the three steel frames 2 are fixed together. Concrete is recycled concrete. . The spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com