Method for preparing sapo-34 molecular sieve membrane by variable temperature method

A technology of SAPO-34 and molecular sieve, which is applied in the field of preparation of SAPO-34 molecular sieve membrane, can solve the problems of molecular sieve membrane thickness, etc., and achieve the effect of reducing mass transfer resistance and increasing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The specific steps of preparing SAPO-34 molecular sieve membrane by the variable temperature method in this embodiment are as follows:

[0034] Step 1, add 2.46g of deionized water to 31.13g of tetraethylammonium hydroxide solution (TEAOH, 35wt%), then weigh 7.56g of aluminum isopropoxide and add it to the aforementioned solution, and stir at room temperature for 2-3 hours; then Add dropwise 1.665g silica sol (40wt%), stir 1 hour; Finally slowly add dropwise 8.53g phosphoric acid solution (H 3 PO 4 , 85wt%), stirred overnight. Microwave heating was used for crystallization at 180°C for 7h. After the product is taken out, it is centrifuged, washed and dried to obtain SAPO-34 molecular sieve seed crystals.

[0035] Step 2: Select a porous ceramic tube with a pore size of 100nm as the carrier, seal both ends of the carrier with glaze, wash and dry, seal the outer surface with PTFE tape, and brush the SAPO-34 molecular sieve seed crystal to the inner surface of the ceram...

Embodiment 2

[0046] The difference from Example 1 is that in step 4, the time for continuing hydrothermal crystallization at 180° C. is 9 h. All the other steps are the same as in Example 1.

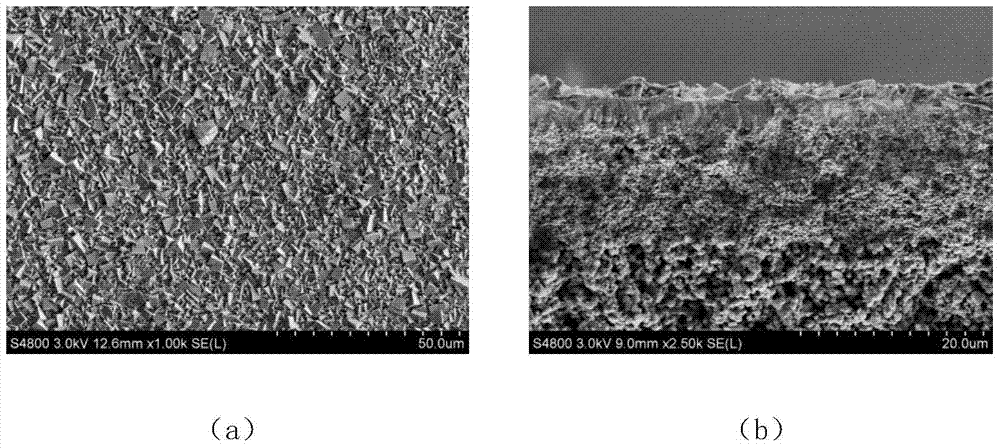

[0047] The surface and profile of gained SAPO-34 molecular sieve membrane are as follows image 3 As shown in the figure, it can be seen from the figure that the surface of the carrier is completely covered by cubic crystals, and the cross-linking between the crystals is good (see figure a); the thickness of the film is relatively uniform, about 1.5 microns (see figure b).

[0048] The CO of the SAPO-34 molecular sieve membrane tube 2 / CH 4 The gas separation test results are shown in Table 2, at 4.0MPa, its CO 2 The permeability is 18.6×10 -7 mol / (m 2 s Pa), CO 2 / CH 4 The separation selectivity is 16.

[0049] The CO of the SAPO-34 molecular sieve membrane tube of table 2 embodiment 2 2 / CH 4 Gas Separation Test Results

[0050]

Embodiment 3

[0052] The difference from Example 1 is that in step 4, the time for continuing hydrothermal crystallization at 180° C. is 16.5 h. All the other steps are the same as in Example 1.

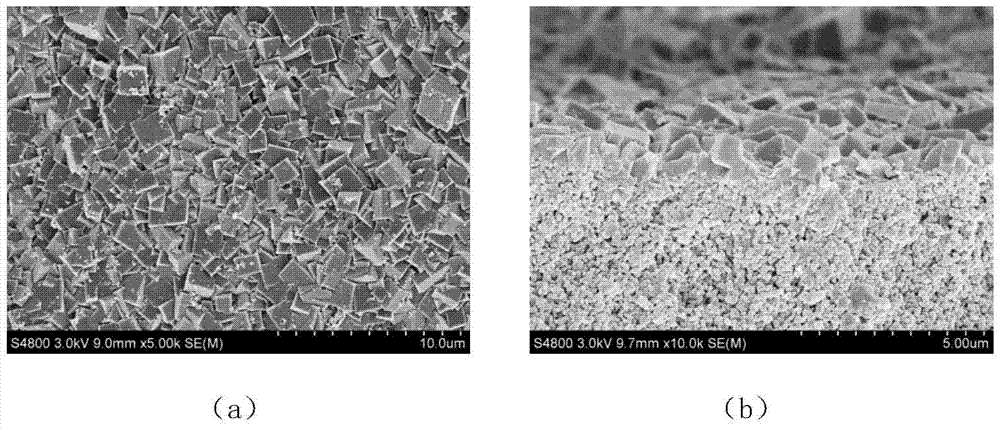

[0053] The surface and profile of gained SAPO-34 molecular sieve membrane are as follows Figure 4 As shown in the figure, it can be seen from the figure that the surface of the carrier is completely covered by cubic crystals, and the cross-linking between the crystals is good (see figure a); the thickness of the film is relatively uniform, about 3.5 microns (see figure b).

[0054] The CO of the SAPO-34 molecular sieve membrane tube 2 / CH 4 The gas separation test results are shown in Table 3, at 4.0MPa, its CO 2 The permeability is 19.5×10 -7 mol / (m 2 s Pa), CO 2 / CH 4 The separation selectivity is 24.

[0055] The CO of the SAPO-34 molecular sieve membrane of table 3 embodiment 3 2 / CH 4 Gas Separation Test Results

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com