A radial zero additional force turntable

An additional force and turntable technology, which is applied in the direction of photolithography process exposure device, microlithography exposure equipment, etc., can solve the problem of not meeting the requirements of axis stability, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the specific implementation of the present invention will be described in detail below.

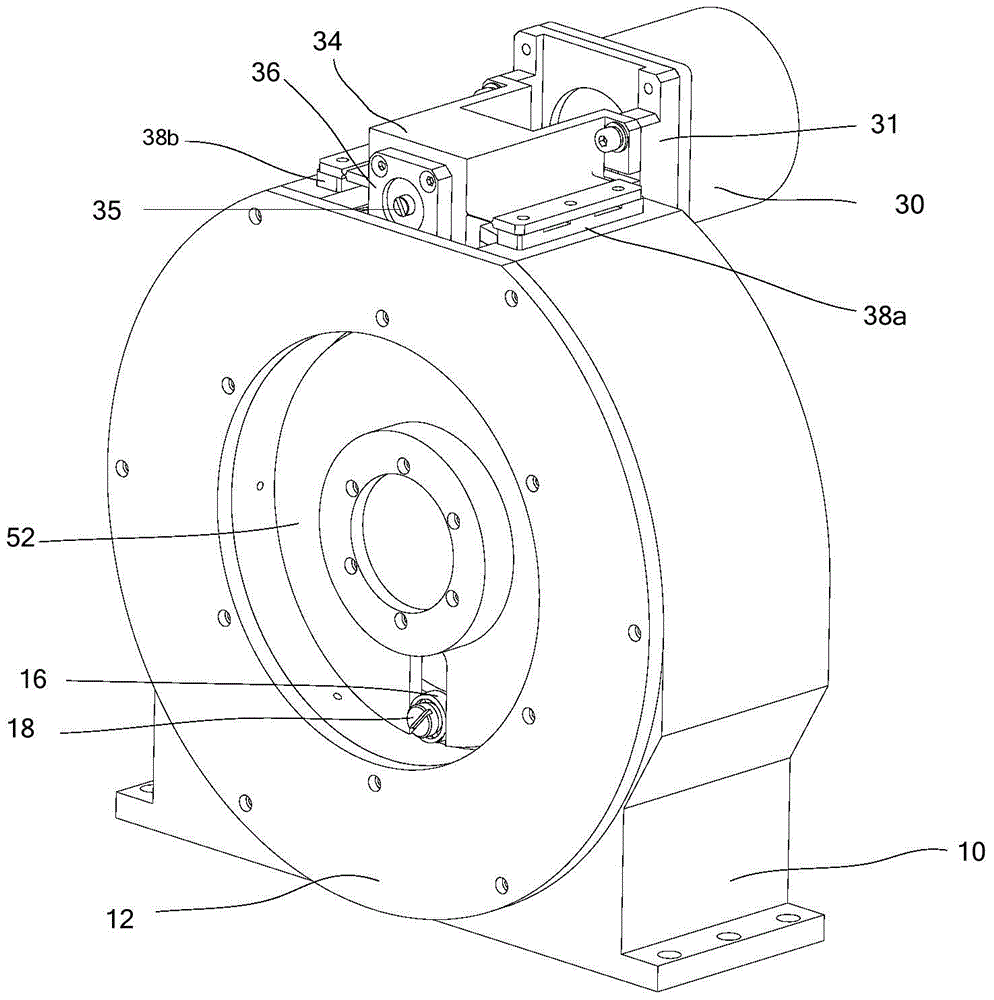

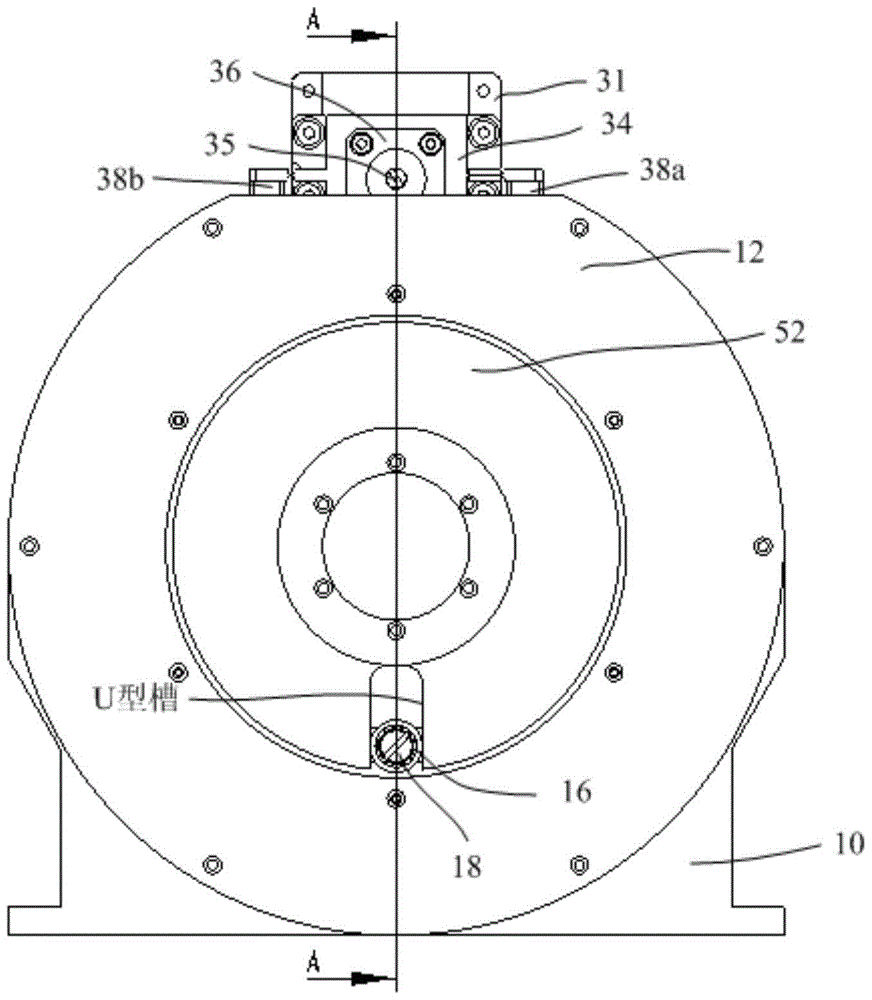

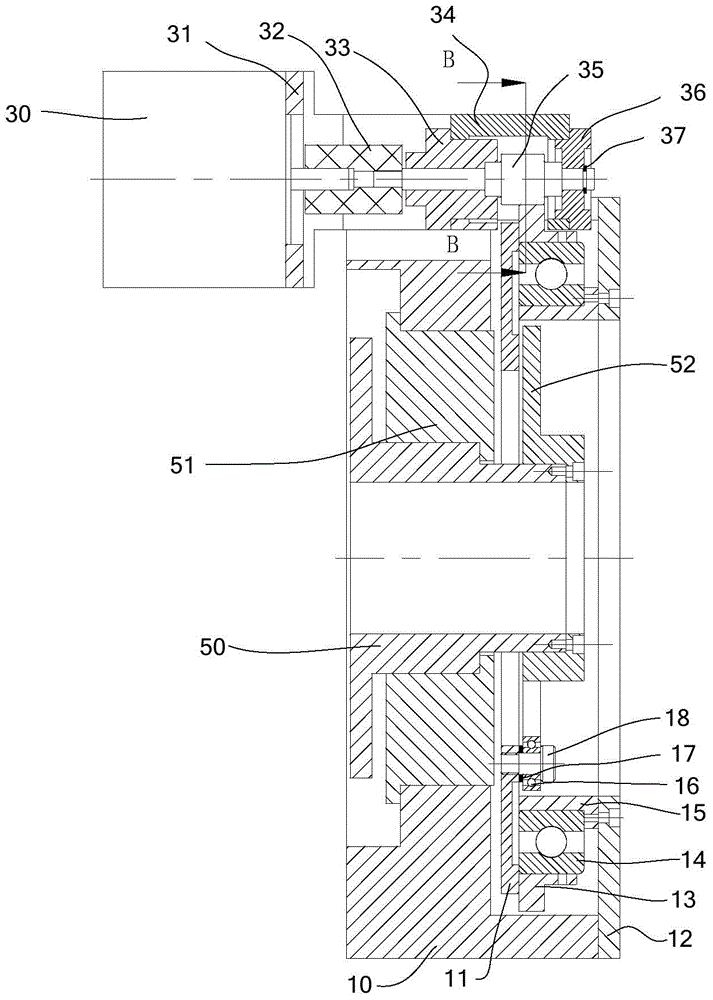

[0025] Such as figure 1 , figure 2 , image 3 As shown, a radial zero additional force turntable of the present invention consists of a base 10, a bearing end cover 11, a cover plate 12, a friction wheel 13, a bearing 14, a stepped shaft 15, a small bearing 16, a gasket 17, a shaft pin 18, Motor 30, motor base 31, shaft coupling 32, fixed bearing 33, roller seat 34, roller 35, support bearing 36, retaining ring 37, spacer 38, workbench 50, code disc 51 and rotating disc 52 form. Wherein the base 10, bearing end cover 11, cover plate 12, friction wheel 13, bearing 14, step shaft 15, small bearing 16, gasket 17, shaft pin 18, motor 30, motor seat 31, coupling 32, fixed Bearing 33, roller seat 34, roller 35, support bearing 36, retaining ring 37 and pad 38 form the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com