Embedding method of metal embedded parts in composite material sandwich structure

A technology of metal embedded parts and sandwich structures, applied in lamination devices, chemical instruments and methods, lamination and other directions, can solve the problems of discontinuous characteristics and delamination of reinforcing fibers, improve fatigue strength and bearing capacity, avoid The effect of layering and meeting the bearing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

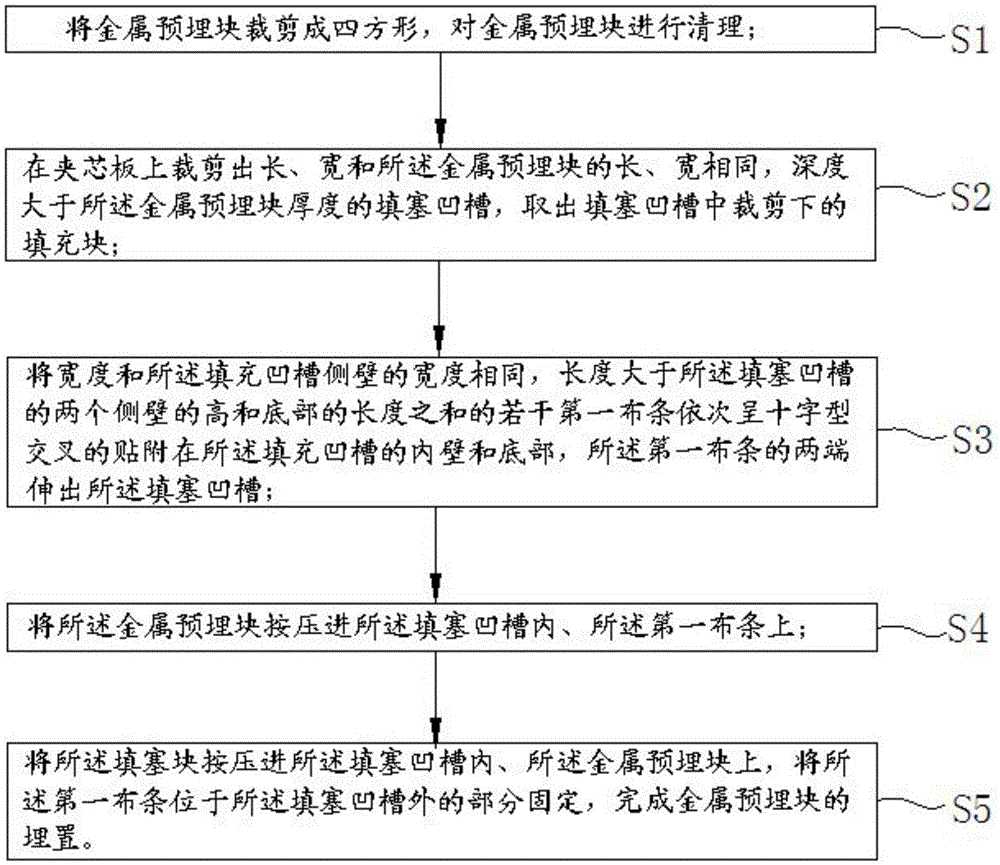

[0037] This embodiment includes the following steps:

[0038] Cut the metal embedded block 4 into a square, and clean the metal embedded block 4, including cleaning the metal embedded block 4 with acetone, polishing the surface of the metal embedded block 4, and using an air gun to blow the surface of the metal embedded block 4 Debris

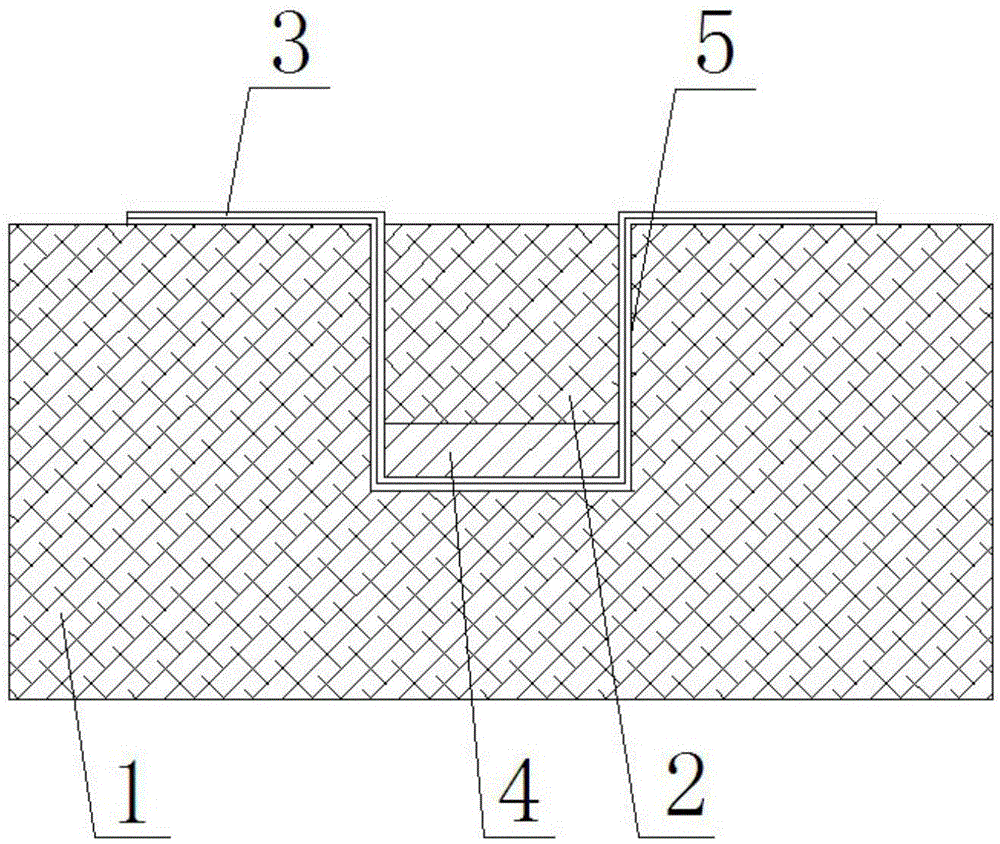

[0039] Cut out a filling groove with the same length and width as the length and width of the embedded part and a depth greater than the thickness of the metal embedded block 4 on the sandwich panel 1, and take out the filling block cut in the filling groove;

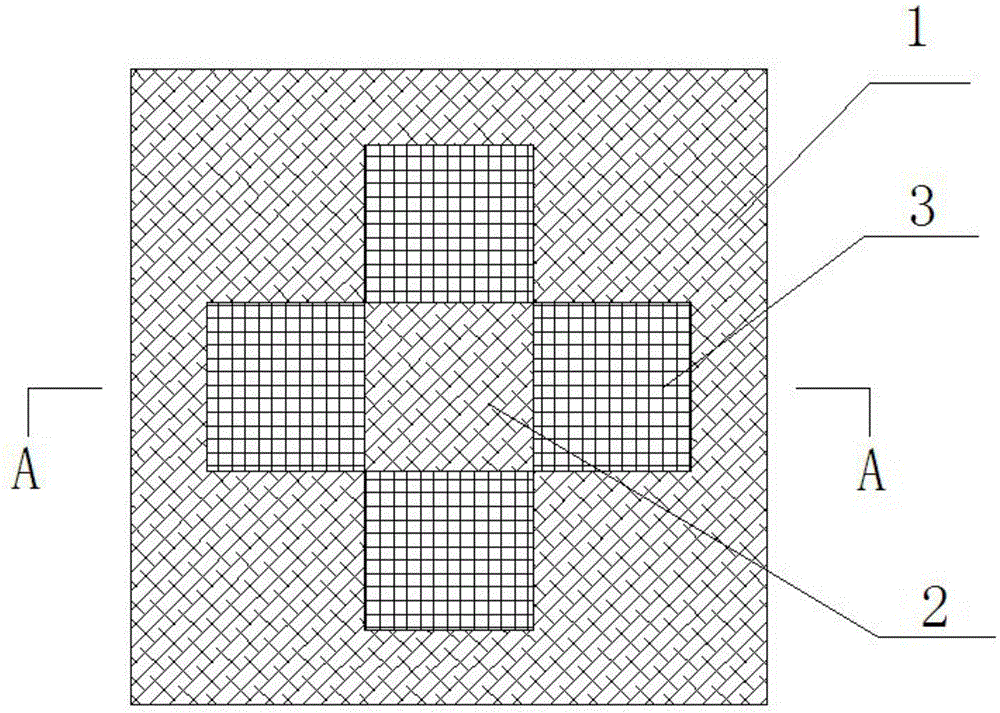

[0040] The first cloth strip 3 having the same width as the width of the filling groove 5, and having a length greater than the sum of the height of the two side walls of the filling groove and the length of the bottom is formed along the edge direction of the filling groove. The crisscross pattern is laid in the filling groove 5 in turn, and attached to the inner wall and bottom of the fillin...

Embodiment 2

[0045] This embodiment includes the following steps:

[0046] Cut the metal embedded block 4 into a square of the required size, and clean the metal embedded block 4, including cleaning the metal embedded block 4 with acetone, polishing the surface of the metal embedded block 4, and blowing the metal embedded block with an air gun Sundries on the surface of block 4;

[0047] Cut out a filling groove with the same length and width as that of the embedded part and a depth greater than that of the metal embedded block 4 on the sandwich panel 1, and take out the filling block cut in the filling groove;

[0048] The first cloth strip 3 having the same width as the width of the filling groove 5, and having a length greater than the sum of the height of the two side walls of the filling groove and the length of the bottom is formed along the edge direction of the filling groove. The criss-cross pattern is laid in the filling groove 5 in turn, and attached to the inner wall and bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com