Manufacturing system

A technology for manufacturing systems and workpieces, applied in general control systems, control/regulation systems, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. In addition, in the description of the drawings, the same reference numerals are given to the same elements, and repeated descriptions are omitted.

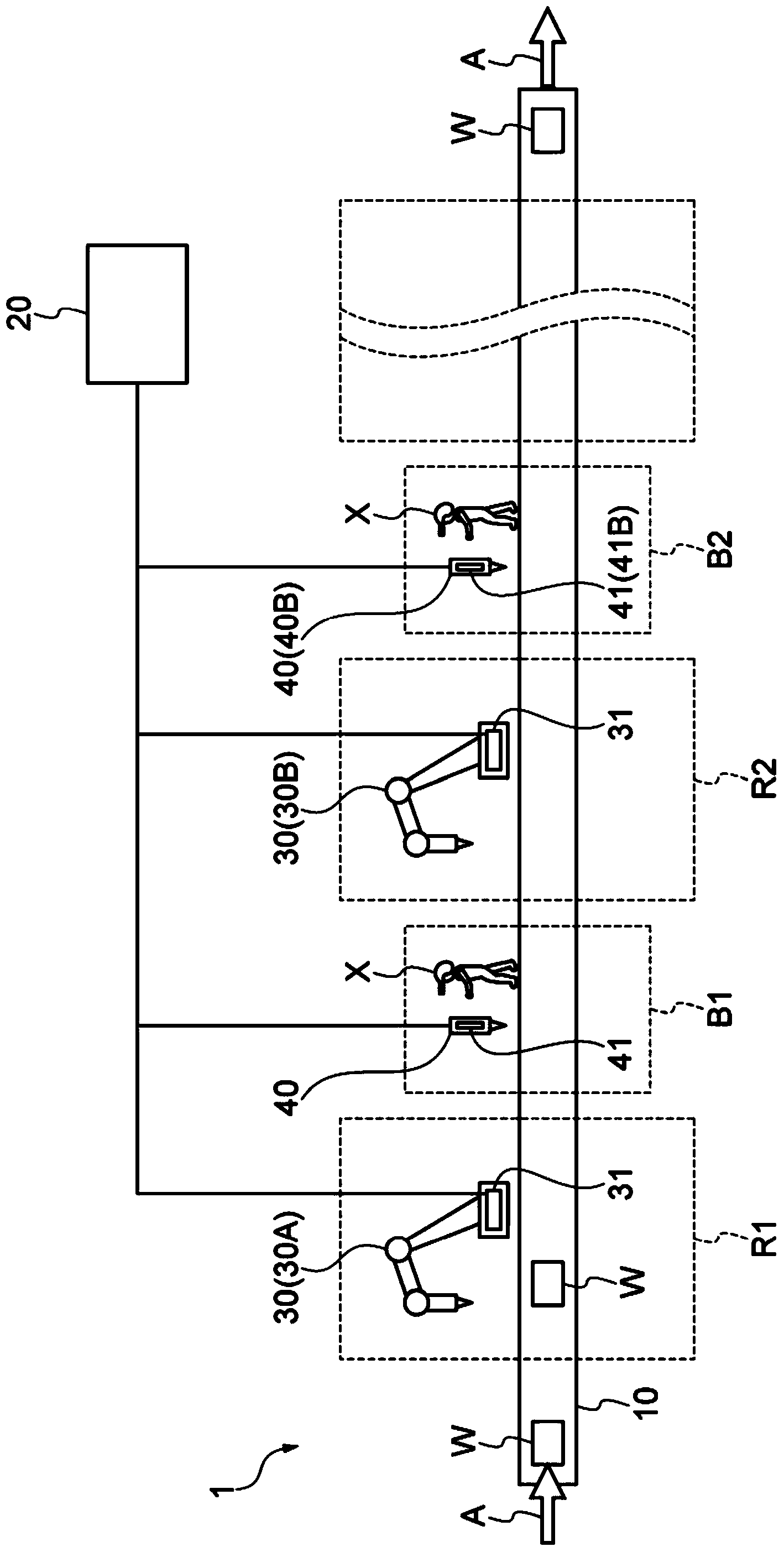

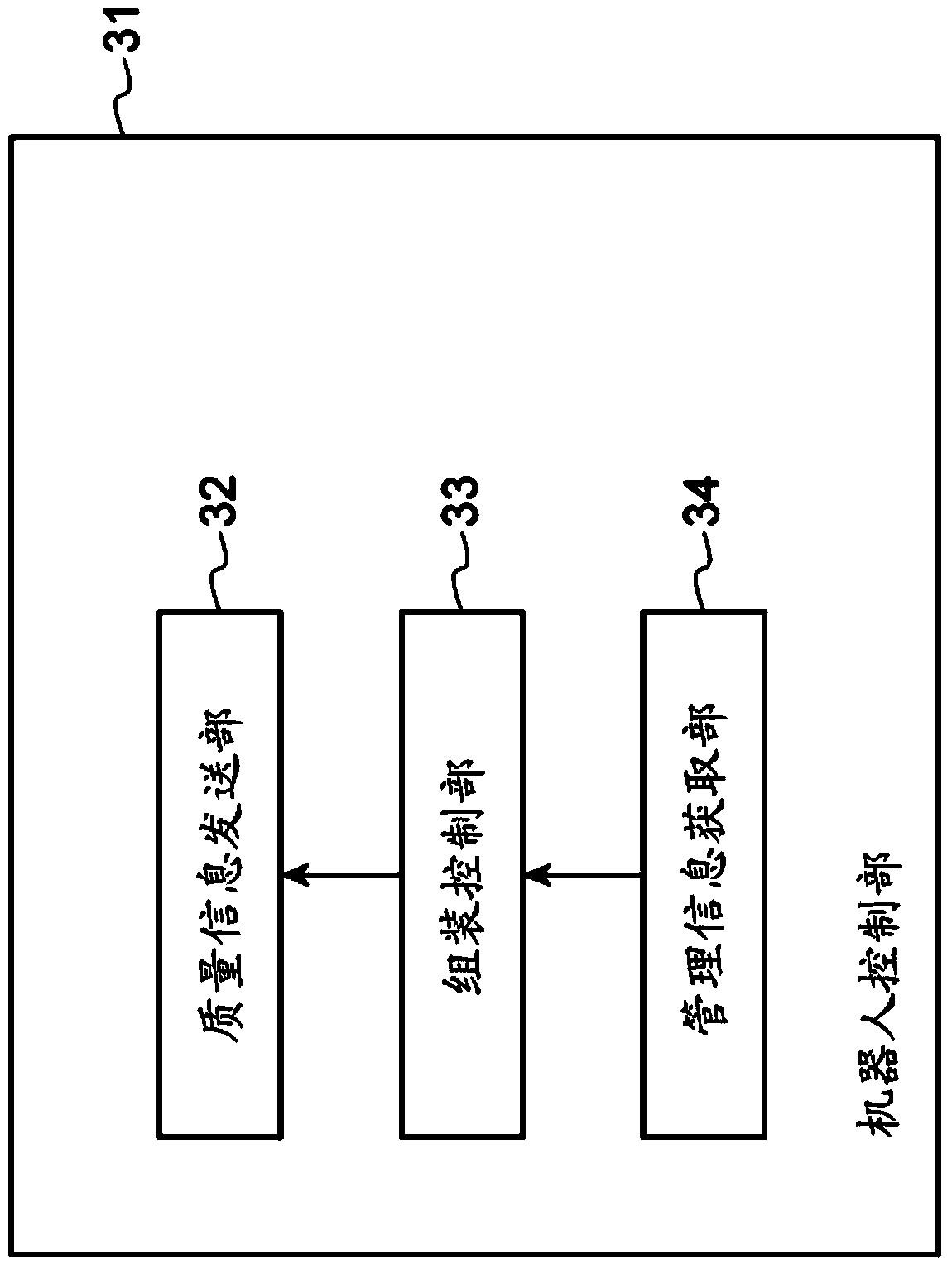

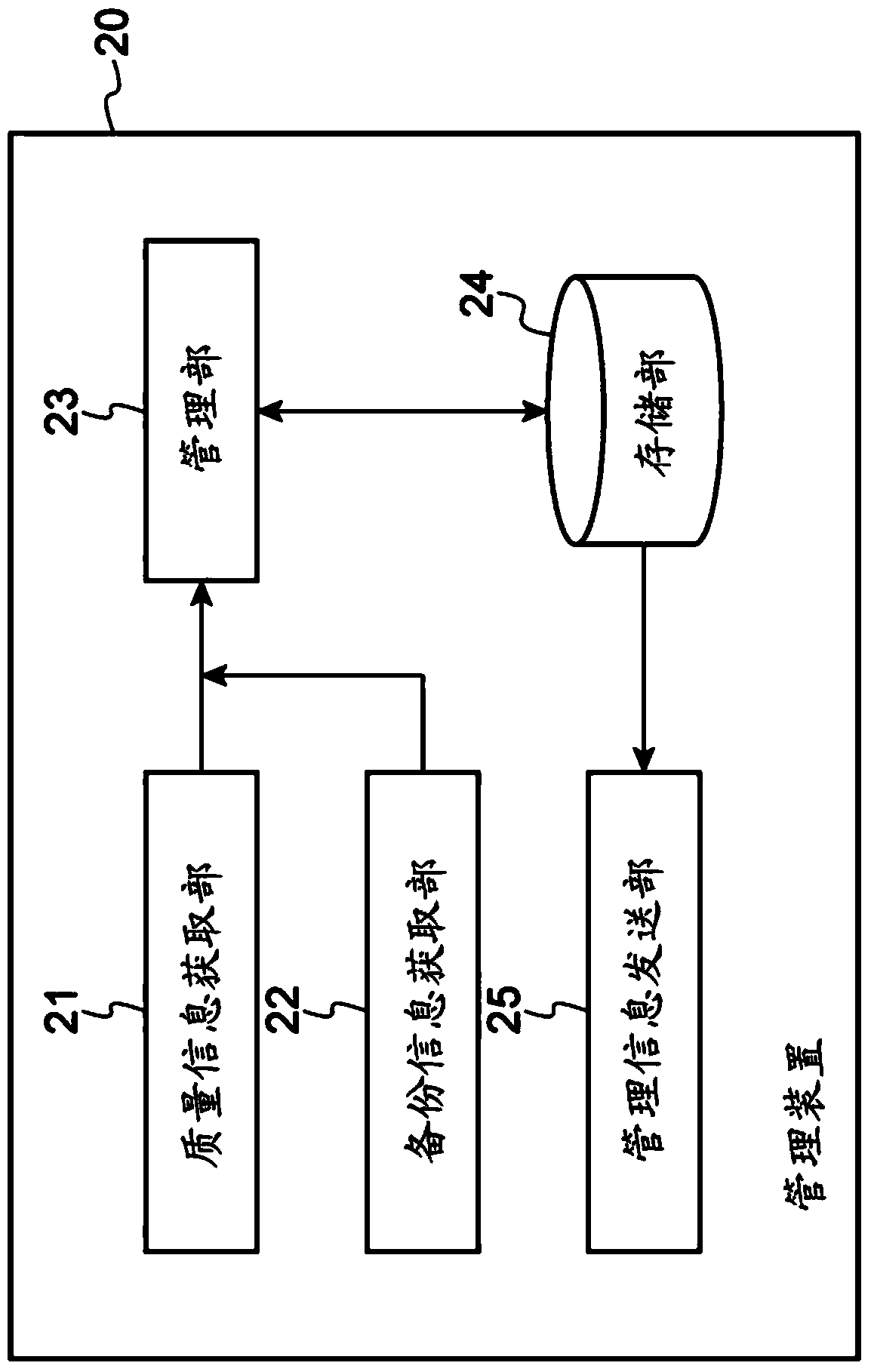

[0024] Such as figure 1 As shown, the manufacturing system 1 is composed of a conveying device 10, a management device 20, a plurality of robots (processing devices) 30, and a plurality of nut wrenches (processing tools) 40. The conveying device 10 is used to convey the workpiece W to be assembled. in figure 1 , The workpiece W is conveyed by the conveying device 10 in the direction of arrow A. As for the workpiece W conveyed by the conveying device 10, the assembly work performed by the robot 30 and the nut wrench 40 is performed.

[0025] A plurality of robots 30 are provided along the extending direction of the conveying device 10. As the robot 30, for example, a robot having an arm for performing assembly work or the lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com