Glue spraying box and glue spraying device comprising same

A technology of glue spraying and glue spraying group, which is applied to the device and coating of surface coating liquid, which can solve the problems of large comprehensive advantages and complicated operation procedures, and achieve improved process precision, stable performance and good quality, and improved utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below:

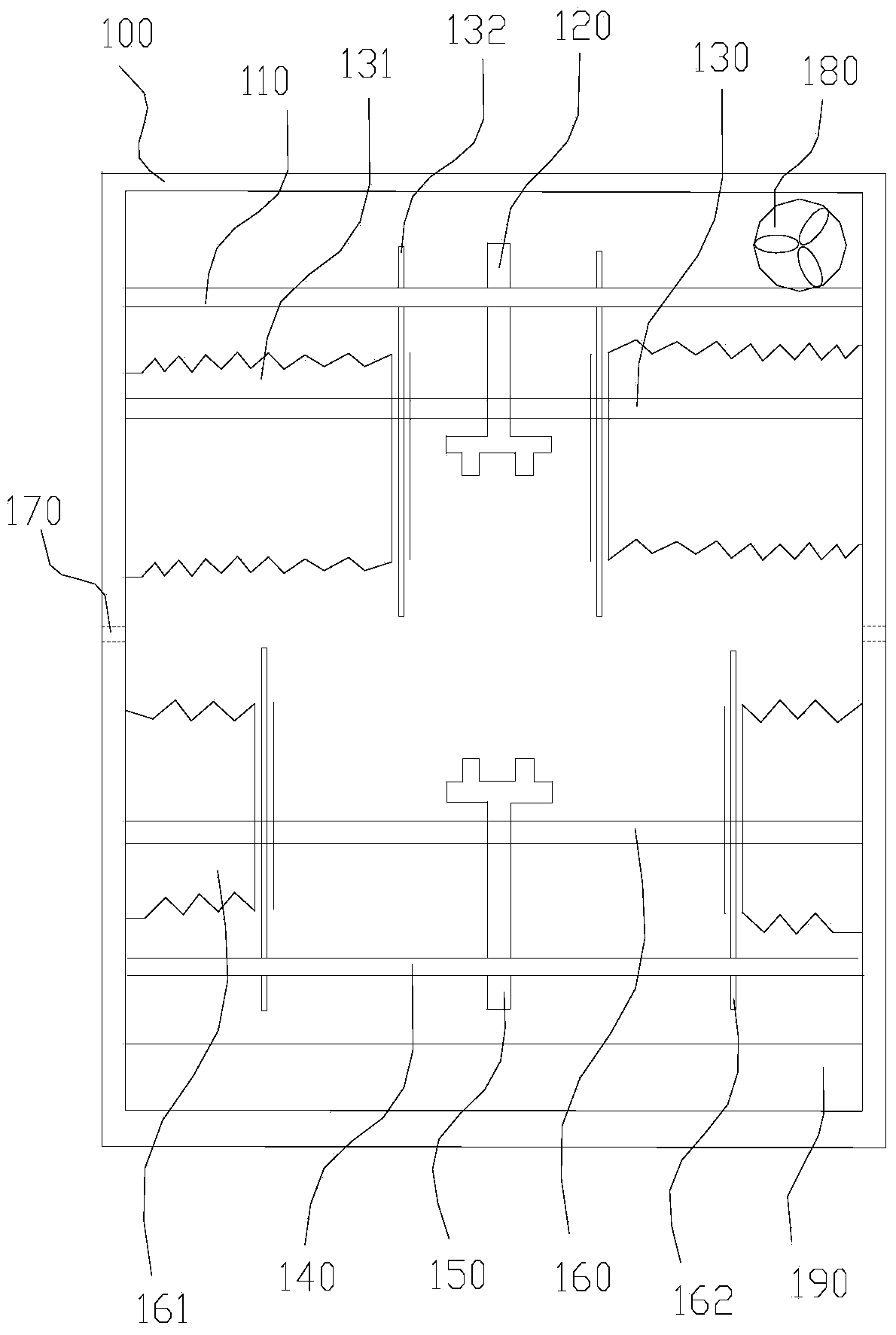

[0028] Such as Figure 1 to Figure 2 Shown is a glue spraying box, including a box body, a first glue spraying group and a second glue spraying group, the box body is provided with a through hole 170 for the base cloth to pass through, and the upper and lower boxes are respectively provided with The first guide rail 110 and the second guide rail 140, the first glue spraying group includes the first hanging rod 121 and the first glue sprayer 120 that is telescopically movable on it, and the first hanging rod 121 forms a sliding connection with the first guide rail 110 , the box is also provided with a first masking group that is compatible with the first glue spraying group, the first masking group includes a first masking guide rail 130 and a first masking device 131 that is telescopically movable on it, The first glue-shielding guide rail 130 is arranged near the first guide rail 110, the first glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com