Adhesive tape

A technology of adhesive tape and adhesive layer, applied in the direction of adhesive, film/sheet adhesive, transportation and packaging, etc., can solve the problem of low rework adaptability, high rework adaptability requirements, expensive components, etc. problems, to achieve the effect of excellent rework adaptability, high design requirements, and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

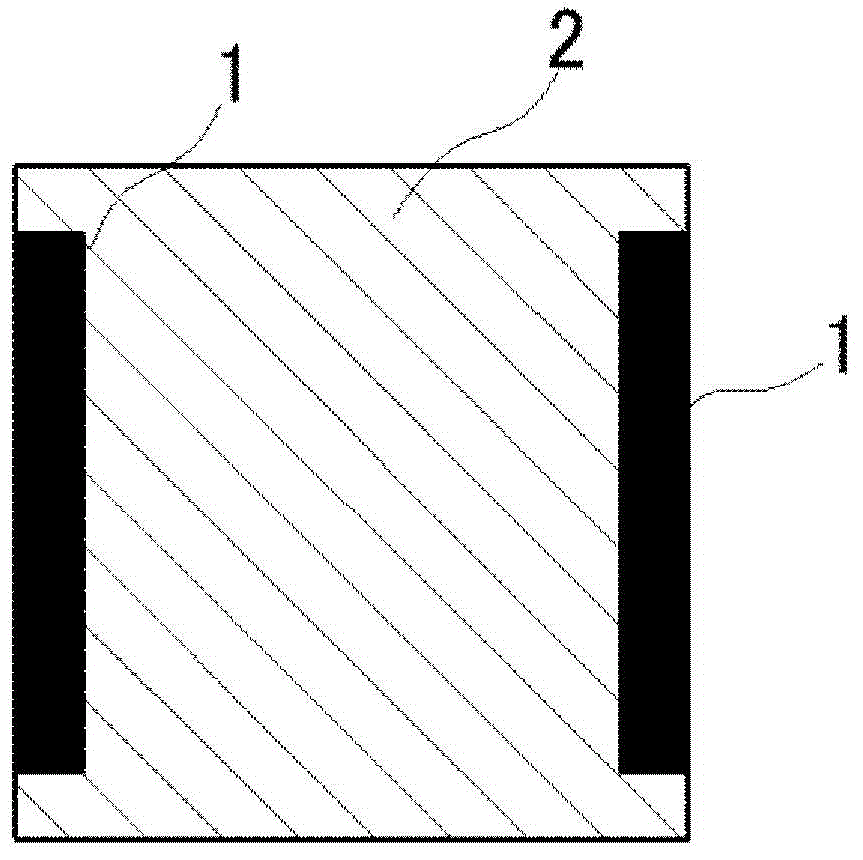

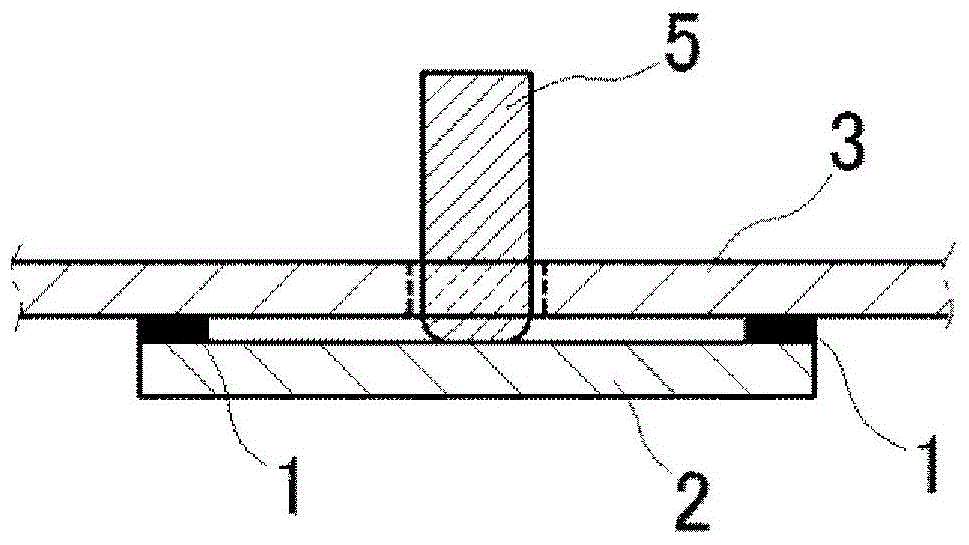

[0132] (Preparation of double-sided adhesive tape)

[0133] Add 1.1 parts by mass of "CORONATE L-45" (isocyanate-based crosslinking agent, 45% solid content) manufactured by Nippon Polyurethane Co., Ltd. to 100 parts by mass of the above-mentioned adhesive composition (A), and stir for 15 minutes to dry The final thickness is 40 μm, and it is coated on the release-treated surface of the PET film with a thickness of 75 μm after release treatment, and dried at 80° C. for 3 minutes to form an adhesive layer. The gel fraction of the pressure-sensitive adhesive layer was 48% by mass, and the temperature showing the peak of the loss tangent (tan δ) at a frequency of 1 Hz was -16°C.

[0134] Next, the black polyolefin-based foam (1) (thickness: 170 μm, apparent density 0.40 g / cm 3 , 25% compressive strength: 346kPa, tensile strength in flow direction: 1124N / cm 2 , Tensile strength in the width direction: 754N / cm 2 , interlayer strength: 31.6N / cm, manufactured by Sekisui Chemical I...

Embodiment 2

[0136] A double-sided adhesive tape with a thickness of 300 μm was obtained in the same manner as in Example 1 except that the thickness after drying of the pressure-sensitive adhesive composition (A) was 65 μm.

Embodiment 3

[0138] Using the adhesive composition (B) instead of the adhesive composition (A), with respect to 100 parts by mass of the adhesive composition (B), add "CORONATE L-45" (isocyanate-based crosslinking agent , solid content 45%) 1.33 parts by mass and stirred for 15 minutes, and then coated on the peeling treatment surface of the PET film with a thickness of 75 μm after the peeling treatment so that the thickness after drying became 65%. A double-sided adhesive tape with a thickness of 300 μm was obtained in the same manner as in Example 1. The gel fraction of the pressure-sensitive adhesive layer was 37% by mass, and the temperature showing the peak of the loss tangent (tan δ) at a frequency of 1 Hz was 2°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com