Al2O3 concentration gradient doped ZnO thin film of crystalline silicon solar cell passivation material and preparation method

A technology of solar cells and concentration gradients, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that passivation films cannot be put into practical use on a large scale, and cannot achieve passivation effects, etc., and achieve strong chemical passivation and field passivation Effect, excellent passivation effect, effect of improving minority carrier lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] There is a layer of Al with a thickness of 1 nm on the silicon wafer 2 o 3 thin film layer, in Al 2 o 3 The thin film layer has a concentration gradient doped ZnO thin film layer, the Al 2 o 3 The concentration gradient doped ZnO thin film layer is composed of Al element, Zn element and O element, among which Al 2 o 3 Concentration Gradient Doping of Al in ZnO Thin Film Layer 2 o 3The proportion decreases from bottom to top, and its resistivity decreases successively. The content of Al element is 0.1%~10%, the thickness is 100nm, and the resistivity is 10Ω·cm~1 ?10 -5 Ω·cm.

[0031] Specific steps are as follows:

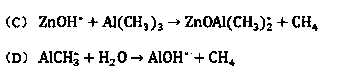

[0032] (1) Place the silicon wafer in the deposition chamber of the atomic deposition equipment, and vacuum the deposition chamber. The deposition temperature is 150°C, the pressure is 0.15 torr, the gas flow rate is 40 sccm, and Al(CH 3 ) 3 The precursor was purged for 20ms, the deposition chamber was cleaned with high-purity nitrogen for 25s, and...

Embodiment 2

[0037] There is a layer of Al with a thickness of 10 nm on the silicon wafer 2 o 3 thin film layer, in Al 2 o 3 The thin film layer has a concentration gradient doped ZnO thin film layer, the Al 2 o 3 The concentration gradient doped ZnO thin film layer is composed of Al element, Zn element and O element, among which Al 2 o 3 Concentration Gradient Doping of Al in ZnO Thin Film Layer 2 o 3 The proportion decreases from bottom to top, and its resistivity decreases successively. The content of Al element is 0.1%~10%, the thickness is 30nm, and the resistivity is 10Ω·cm~1 ?10 -5 Ω·cm.

[0038] The specific steps are as follows:

[0039] (1) Place the silicon wafer in the deposition chamber of the atomic deposition equipment, evacuate the deposition chamber, and inject Al(CH 3 ) 3 Precursor, cleaning the deposition chamber with high-purity nitrogen gas and passing water vapor into the deposition chamber as an oxygen source, and then cleaning the deposition chamber with ...

Embodiment 3

[0044] A layer of Al with a thickness of 5 nm on the silicon wafer 2 o 3 thin film layer, in Al 2 o 3 The thin film layer has a concentration gradient doped ZnO thin film layer, the Al 2 o 3 The concentration gradient doped ZnO thin film layer is composed of Al element, Zn element and O element, among which Al 2 o 3 Concentration Gradient Doping of Al in ZnO Thin Film Layer 2 o 3 The proportion decreases successively from bottom to top, and its resistivity decreases successively. The content of Al element is 0.1%~10%, the thickness is 50nm, and the resistivity is 10Ω·cm~1 ?10 -5 Ω·cm.

[0045] The specific steps are as follows:

[0046] (1) Place the silicon wafer in the deposition chamber of the atomic deposition equipment, evacuate the deposition chamber, and inject Al(CH 3 ) 3 Precursor, cleaning the deposition chamber with high-purity nitrogen gas and passing water vapor into the deposition chamber as an oxygen source, and then cleaning the deposition chamber wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com