A burner structure optimization method based on response surface method

A technology of response surface method and optimization method, which is applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., can solve the problems of complex burner structure and inability to determine cross-effects, etc., and achieve combustion effects and low-nitrogen combustion effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A burner structure optimization method based on the response surface method, the specific steps are:

[0040] (1) Determine the structural factors that need to be considered by the burner, and perform code transformation on them;

[0041] The structural factors are one or more combination of combustion channel, spray gun, burner, combustion channel shape, diameter, spray gun position, nozzle angle and nozzle diameter;

[0042] The coding transformation described is: in the response surface design, the variation ranges of the structural factors are different, and the ranges of some independent variables are extremely different; for the convenience of unified processing, the values of the design parameters are coded and transformed to establish The one-to-one correspondence between the level value of the structural factor and the "coding"; the coding is to solve the troubles caused by different dimensions to the design and analysis;

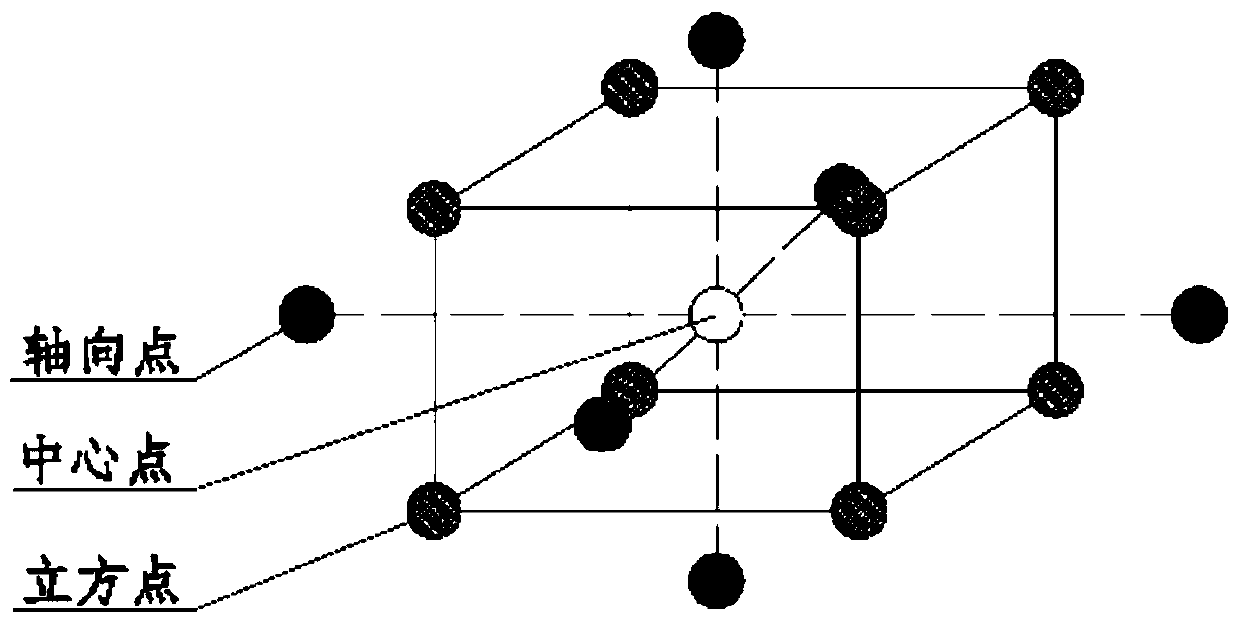

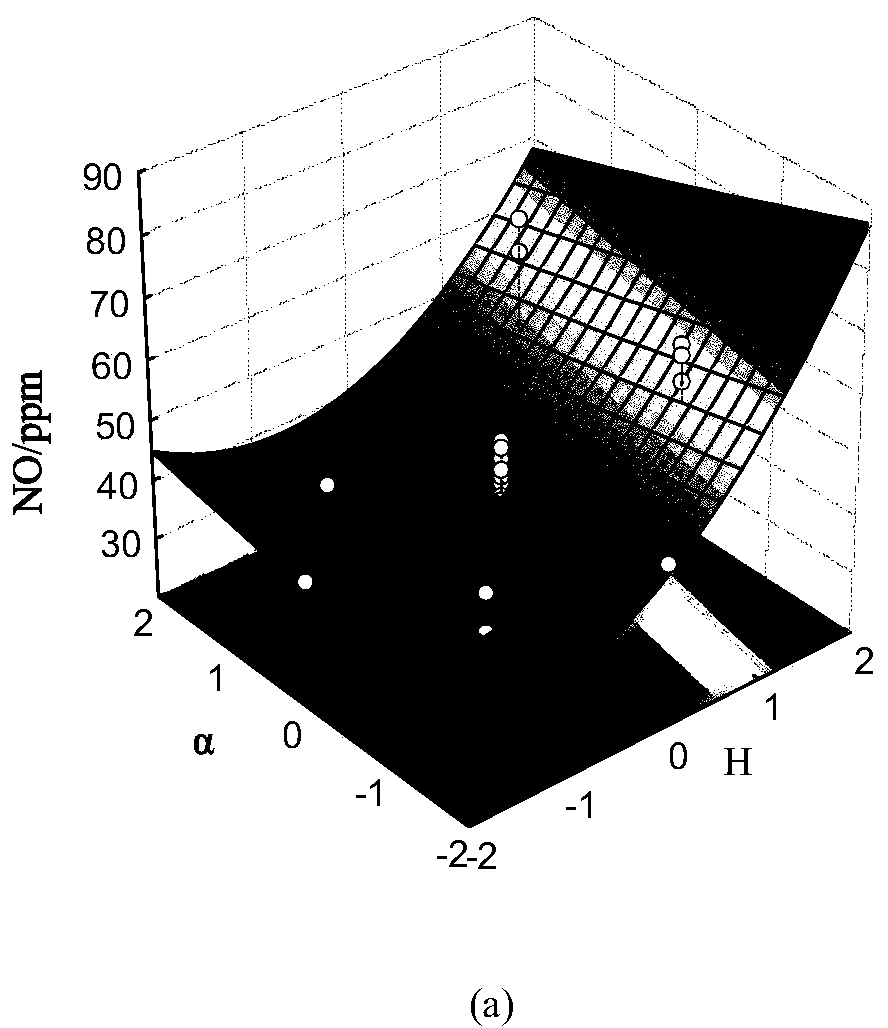

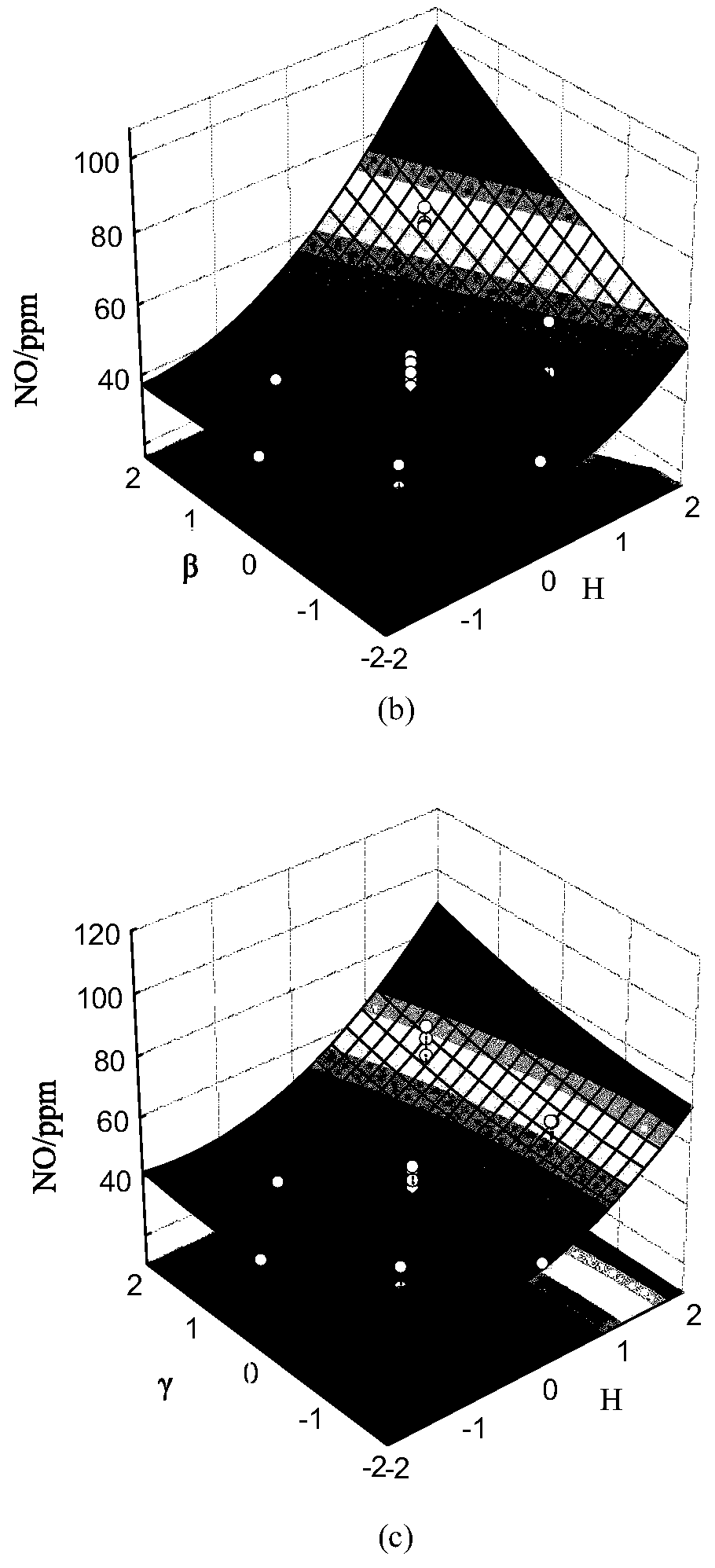

[0043] (2) Using central composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com