Low-nitrogen combustion device with free dispersion pre-mixing combustion layer and combustion head thereof

A technology of premixed combustion and low-nitrogen combustion, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of reducing boiler service life, increasing maintenance rate, and enlarging the burner body, so as to reduce low nitrogen oxides generation, avoiding local high temperature points, and enhancing the effect of premixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

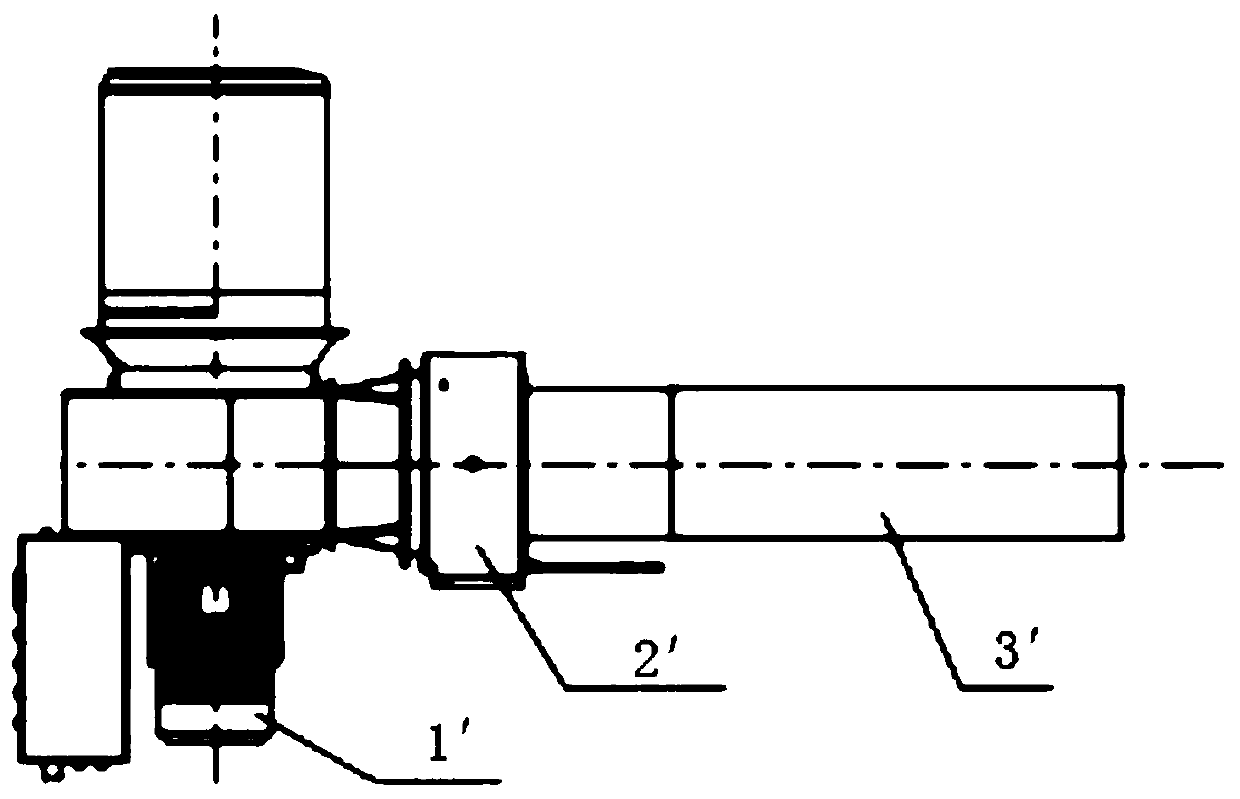

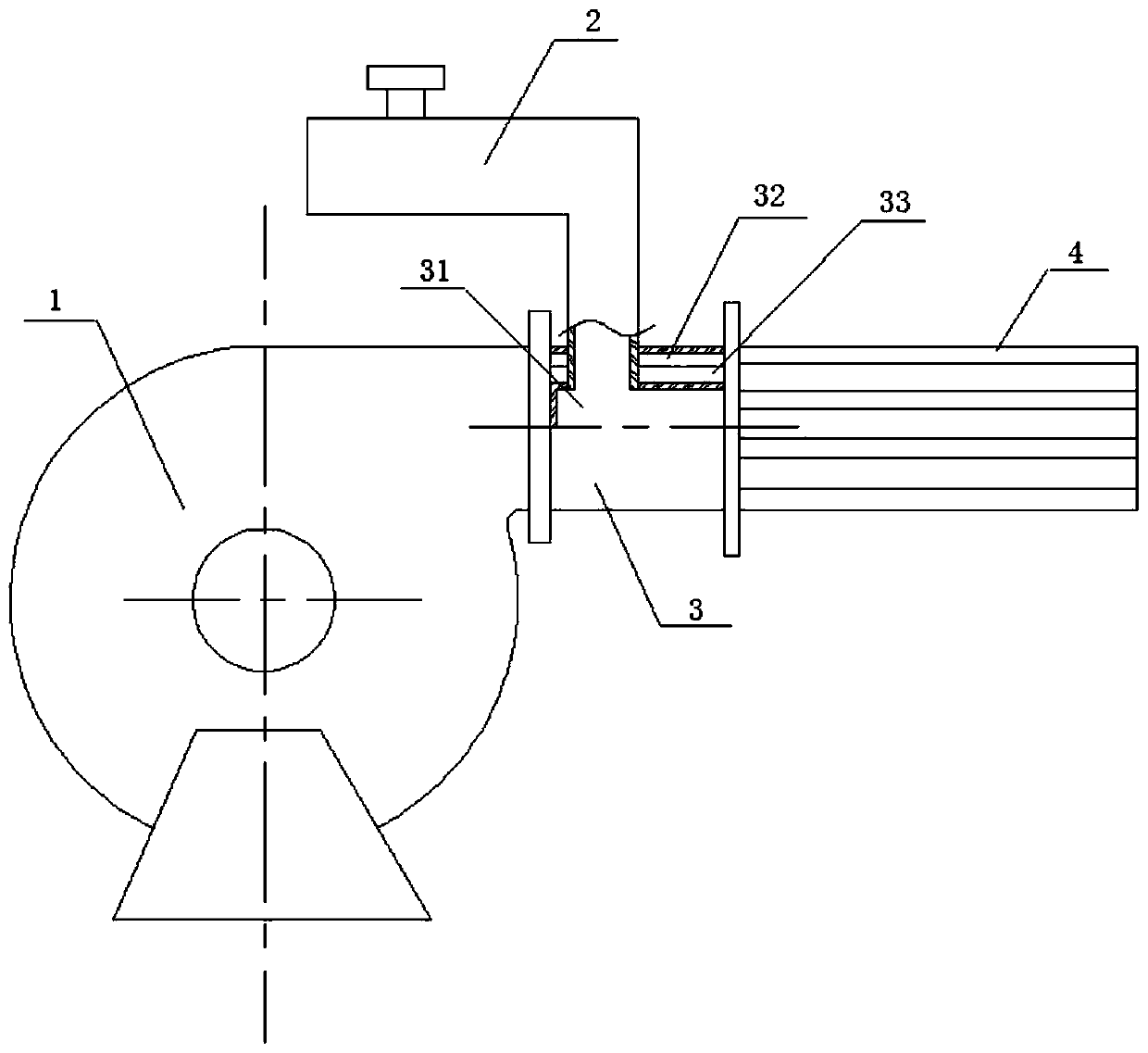

[0083] Such as Figure 2-4 Said, the low-nitrogen combustion head with free-diffusion premixed combustion layer of the present invention includes a combustion head body which is provided with a central pipe, several first ring pipes, and several second ring pipes , Free diffusion premixed combustion layer; among them:

[0084] The central pipeline is arranged along the central line of the combustion head body;

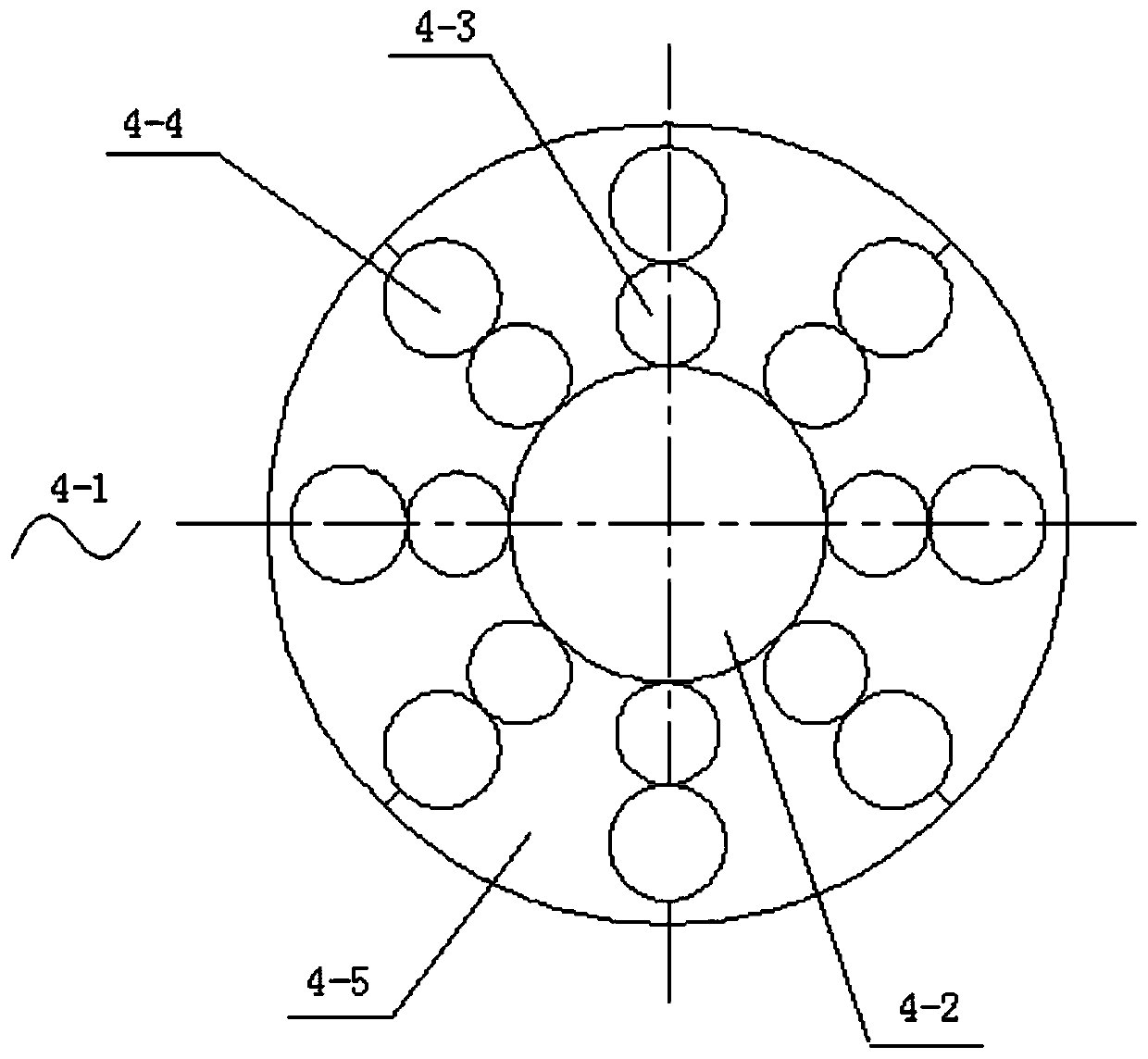

[0085] Each of the plurality of first ring-layer pipes is arranged at the first ring layer outside the central pipe; each of the plurality of second-ring layer pipes is arranged at the periphery of the central pipe The second ring layer;

[0086] Each first ring layer pipe is circumscribed to the central pipe, and each first ring layer pipe is circumscribed to a second ring layer pipe; and the center of each first ring layer pipe is circumscribed to the first ring layer The center of the second ring layer of the pipeline and the center of the center pipeline are collinear; ...

Embodiment 2

[0095] Such as figure 2 , 5 As shown in -10, the gas molecule collision diffusion premixed low-nitrogen combustion head of the present invention includes a combustion head body provided with a central pipe, several first ring pipes, and several second ring pipes , Free diffusion premixed combustion layer; among them:

[0096] The central pipeline is arranged along the central line of the combustion head body;

[0097] Each of the plurality of first ring-layer pipes is arranged at the first ring layer outside the central pipe; each of the plurality of second-ring layer pipes is arranged at the periphery of the central pipe The second ring layer;

[0098] Each first ring layer pipe is circumscribed to the central pipe, and each first ring layer pipe is circumscribed to a second ring layer pipe; and the center of each first ring layer pipe is circumscribed to the first ring layer The center of the second ring layer of the pipeline and the center of the center pipeline are collinear; ...

Embodiment 3

[0127] The invention can select free diffusion premixed combustion layers with different thicknesses according to different requirements. The free diffusion premixed combustion layer of different thickness may form different air-gas mixing methods. In addition to the two methods described in Example 1 and Example 2, it also includes:

[0128] When the distance D between the inner ring sector and the outer wall of the central pipe meets 1 / 4 R1≤D When

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com