Plug-removing agent for low-permeability heterogeneous sandstone reservoir and its application method

A sandstone reservoir, heterogeneous technology, applied in the direction of chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problem of limited improvement of low-permeability formations, increase the effective penetration distance of active acids, and fail to achieve To effectively remove plugging and other problems, achieve the effects of removing drilling mud pollution, improving formation permeability, and increasing formation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

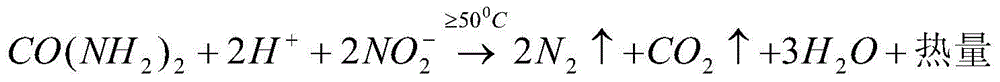

[0035] A plug-removing agent for low-permeability heterogeneous sandstone reservoirs includes agent A, agent B and agent C. The components of agent A, agent B and agent C and the weight percentages of each component are as follows:

[0036] Agent A is composed of sodium nitrite 10%, hydrochloric acid 8% and water 82%; agent B is composed of urea 10%, sodium lauryl sulfate 0.3%, polyacrylamide 0.3% and water 89.4%; agent C is composed of HCL8% , organic phosphoric acid 6%, NH 4 HF 2 2%, cetylamine 0.5%, edetate 0.5% and water 83%.

[0037] The volume ratio of agent A, agent B and agent C is 1:2:2, and the total injection volume of agent A, agent B and agent C depends on the formation conditions.

Embodiment 2

[0039] A plug-removing agent for low-permeability heterogeneous sandstone reservoirs includes agent A, agent B and agent C. The components of agent A, agent B and agent C and the weight percentages of each component are as follows:

[0040] Agent A is composed of sodium nitrite 25%, hydrochloric acid 12% and water 63%; agent B is composed of urea 15%, sodium lauryl sulfate 1.2%, polyacrylamide 0.6% and water 83.2%; agent C is composed of HCL12% , organic phosphoric acid 10%, NH 4 HF 2 5%, cetylamine 1.5%, EDTA 1.5% and water 70%.

[0041] The volume ratio of agent A, agent B and agent C is 1:1.8:2, and the total injection amount of agent A, agent B and agent C depends on the formation conditions.

Embodiment 3

[0043] A plug-removing agent for low-permeability heterogeneous sandstone reservoirs includes agent A, agent B and agent C. The components of agent A, agent B and agent C and the weight percentages of each component are as follows:

[0044] Agent A is composed of sodium nitrite 18%, hydrochloric acid 10% and water 72%; agent B is composed of urea 13%, sodium lauryl sulfate 0.8%, polyacrylamide 0.5% and water 85.7%; agent C is composed of HCL10% , organic phosphoric acid 8%, NH 4 HF 2 4%, cetylamine 1%, EDTA 1% and water 76%.

[0045] The volume ratio of agent A, agent B and agent C is 1:2.3:2.2. The total injection volume of agent A, agent B and agent C depends on the formation conditions.

[0046] When using on-site, follow the steps below:

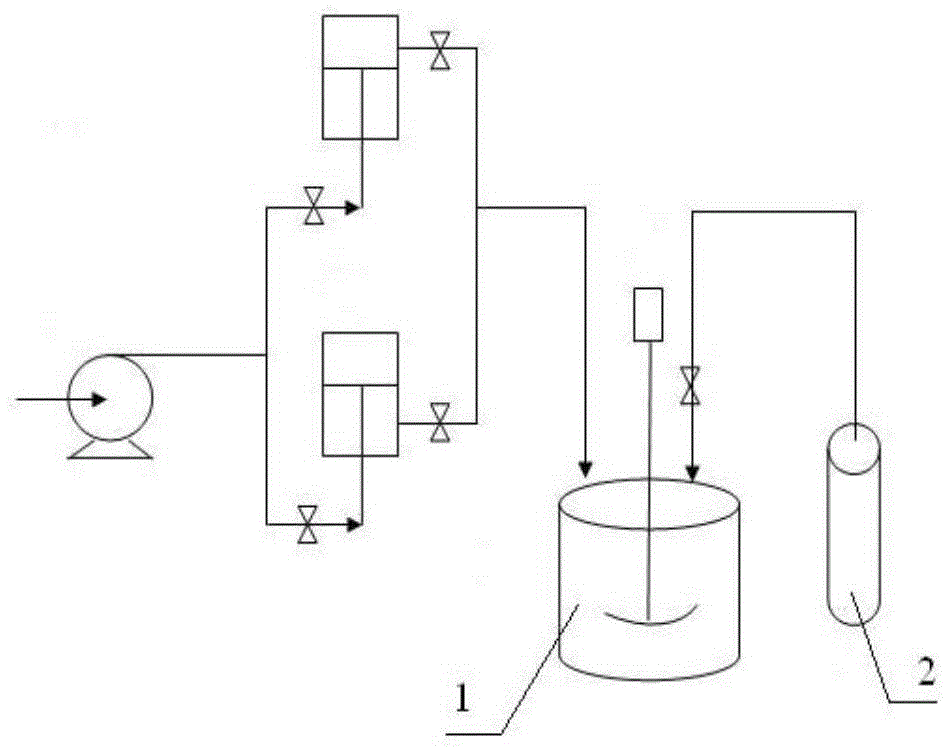

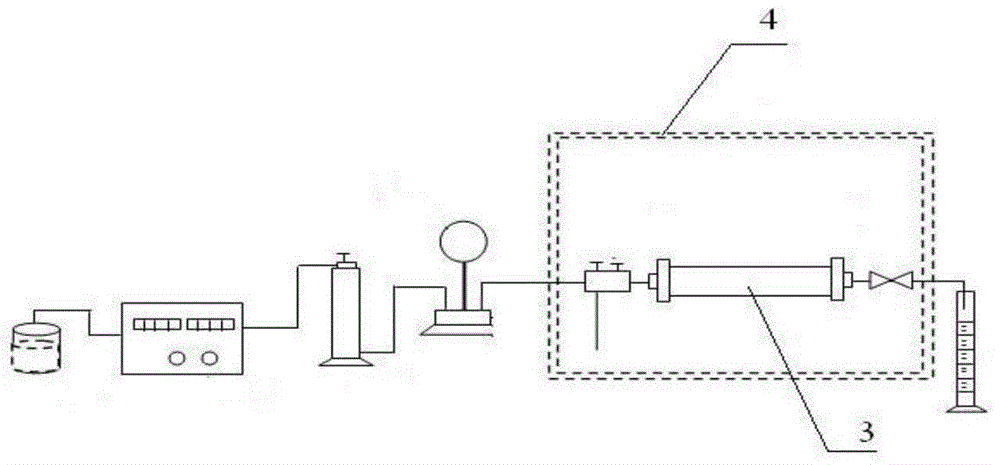

[0047] The first step: take the components and materials disclosed in the foregoing embodiment 1 or embodiment 2 or embodiment 3, respectively prepare agent A, agent B and agent C in three liquid mixing tanks, and prepare them under n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com