Polymer ion liquid electrolyte and preparation method thereof

A technology of ionic liquid and composite electrolyte, which is applied in the field of polymer ionic liquid electrolyte and its preparation, can solve the problems that the electrolyte has not been reported, and achieve the effect of improving solubility, good thermal stability, and high lithium ion migration number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0048] Embodiment 1-5 is the preparation of ionic liquid polymer monomer

Embodiment 1

[0049] Example 1: Preparation of 1-vinyl-3-methoxyethyl-imidazole bis(fluorosulfonyl)imide salt (Vy-IM for short 102 FSI)

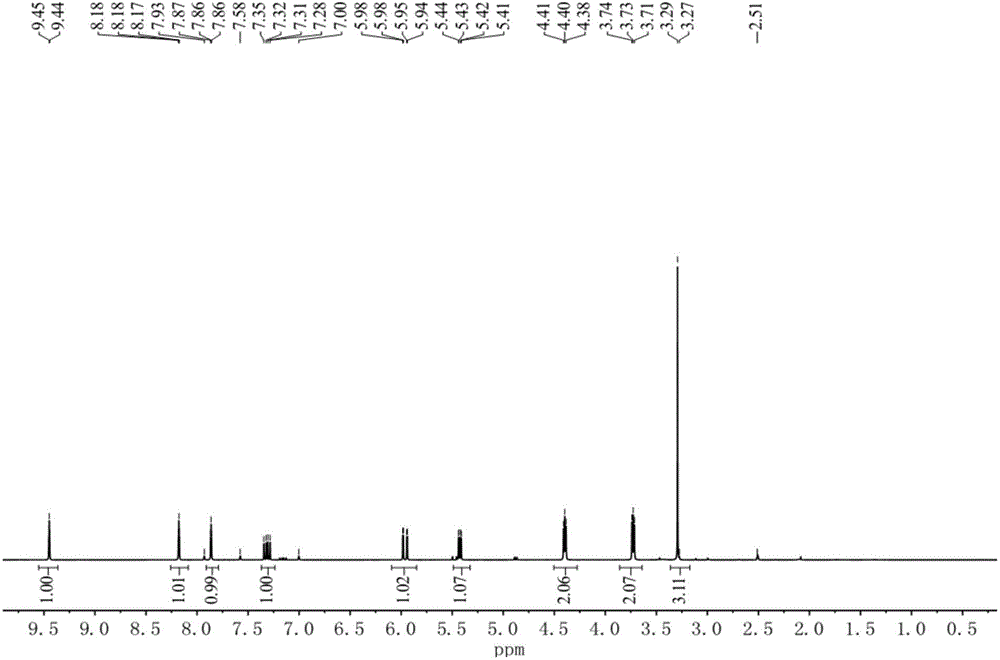

[0050] Add 10.0g (0.110mol) of vinylimidazole and 20mL of acetone into a 50mL three-necked flask, add dropwise 23.7g (0.127mol) of iodoethyl methyl ether under stirring in an ice bath, stir for half an hour, then stir at room temperature for 12h, the reaction is completed, and the rotary evaporation Remove the low-boiling solvent, wash twice with ether, and dry in vacuum at 40°C for 12 hours to obtain 24.6 g (0.088 mol) of 1-vinyl-3-methoxyethyl-imidazolium iodide salt.

[0051] Dissolve 10.0 g (0.036 mol) of 1-vinyl-3-methoxyethyl-imidazolium iodide salt prepared above in 20 mL of deionized water, add 7.9 g (0.036 mol) of KFSI and 20 mL of CH 2 Cl 2 , stirred and reacted for 4h, stood to separate the water phase, and washed the organic phase with deionized water until 5% AgNO 3 There was no precipitation in the aqueous solution, and the low-boiling so...

Embodiment 2

[0053] Example 2: Preparation of 2-(methacryloyloxy)-N-(2-methoxyethyl)-N,N-dimethylethyl quaternary ammonium bis(fluorosulfonyl)imide

[0054] Add 10.0g (0.064mol) dimethylaminoethyl methacrylate (DMAEMA) and 20mL acetone to a 50mL three-necked flask, add 13.0g (0.070mol) iodoethyl methyl ether dropwise under stirring in an ice bath, stir for half an hour, then room temperature Stir for 12 hours, the reaction is complete, remove the low-boiling point solvent by rotary evaporation, wash twice with ether, and dry in vacuum at 40°C for 12 hours to obtain 2-(methacryloyloxy)-N-(2-methoxyethyl )-N, N-dimethylethyl quaternary ammonium iodide salt 17.5g (0.051mol).

[0055] Dissolve 10.0 g (0.029 mol) of 1-vinyl-3-methoxyethyl-imidazolium iodide salt prepared above in 20 mL of deionized water, and add 6.4 g (0.029 mol) of potassium bis(fluorosulfonyl)imide and 20mL CH 2 Cl 2 , stirred and reacted for 4h, stood to separate the water phase, and washed the organic phase with deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com