Method for preparing tianeptine sodium intermediate

A technology for tianuptine sodium and intermediates, which is applied in the field of preparation of pharmaceutical intermediates, can solve the problems of large waste water, serious pollution, and high energy consumption, and achieve the effects of less three wastes, no discharge of three wastes, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

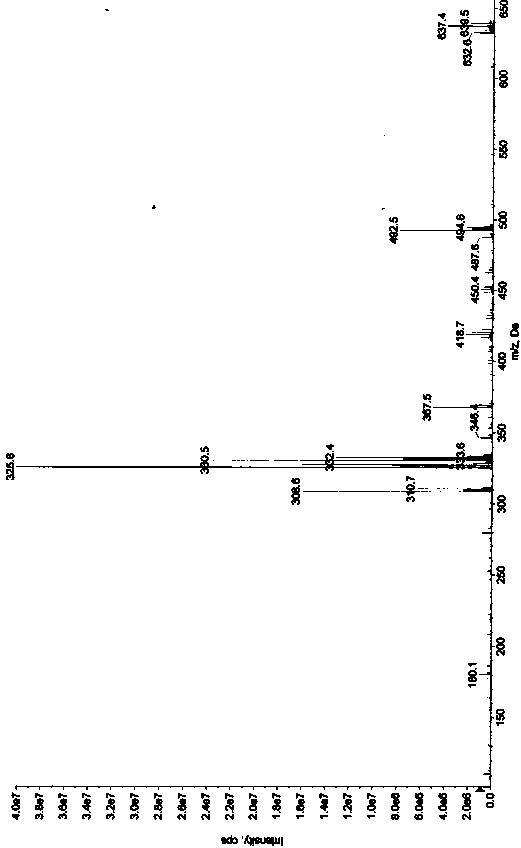

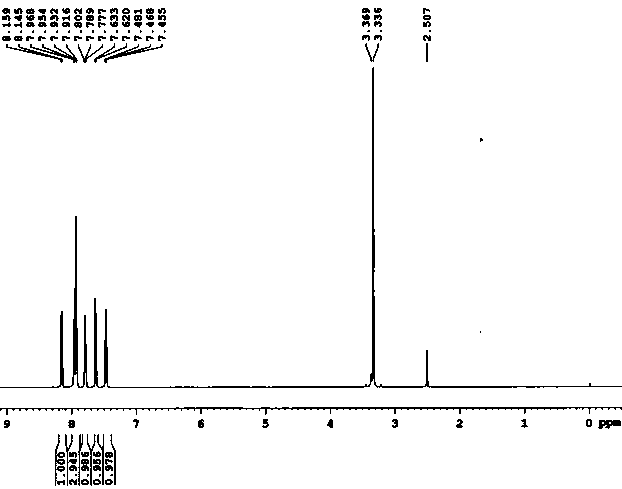

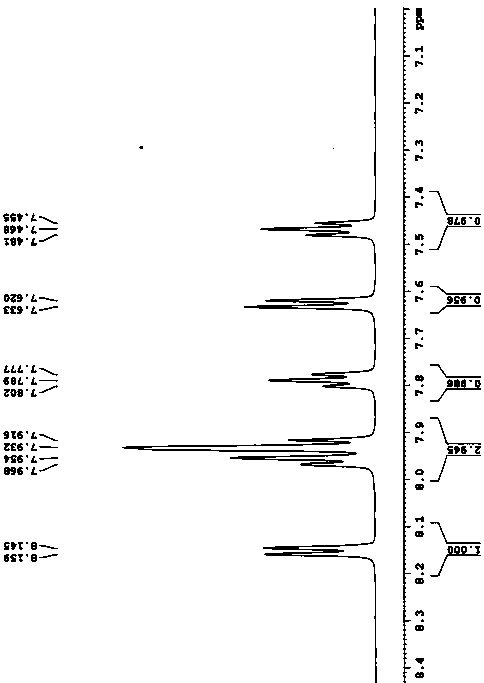

Image

Examples

Embodiment 1

[0031] Catalytic preparation of intermediate A by polyphosphoric acid

[0032] Add 339KG of intermediate B into a 2000L reactor, slowly add 700KG of polyphosphoric acid, turn on the steam and heat to about 40 degrees, turn on the stirring, raise the temperature to 75 degrees and react for 4 hours. The complete conversion of intermediate B was monitored by liquid phase, the temperature was lowered to 30°C, poured into 800KG of ice water, continued to cool down to 10°C, kept warm and crystallized for 2 hours, and centrifuged to obtain a white solid with a wet weight of 386KG, HPLC: 98.2%.

[0033] Transfer the obtained solid to the reaction kettle, which contains 1300KG of 95% ethanol in advance. After heating and dissolving completely, cool down to 5 degrees to crystallize for 4 hours, centrifuge and dry the refined product at 60 degrees to obtain a total of 292KG of finished products, with a yield of 95.1 %, HPLC: 99.8%

[0034] The refined mother liquor is distilled and conc...

Embodiment 2

[0037] Catalyzed Preparation of Intermediate A by Sulfuric Acid

[0038] Add 339KG of intermediate B into a reactor containing 780KG of concentrated sulfuric acid, raise the temperature to 40°C, start stirring, continue to heat up to 65°C, and react for 5 hours. High-efficiency liquid phase monitors the complete conversion of intermediate B, lowers the temperature to 20 degrees, and slowly transfers the reaction solution to a reactor containing 1000KG of ice water, and cools the temperature with ice-salt water, and the temperature control is not higher than 50 degrees. After the transfer is completed, cool down to 8 degrees and crystallize for 3 hours, and centrifuge to obtain a white solid with a wet weight of 389KG, HPLC: 98.8%

[0039] The obtained solid was transferred to the reaction kettle, and there was 1400KG of pre-injected methanol in the kettle. After heating and dissolving completely, the temperature was lowered to 6 degrees to crystallize for 6 hours. HPLC: 99.9%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com