Small solar multistage falling film evaporation heat regeneration type seawater desalting device

A technology of falling film evaporation and solar energy, which is applied in the field of solar energy, can solve the problems of large and expensive systems, expensive vacuum pumps, and low temperature of heat sources, and achieve the effects of improving evaporation heat transfer coefficient, facilitating transportation and installation, and reducing device costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

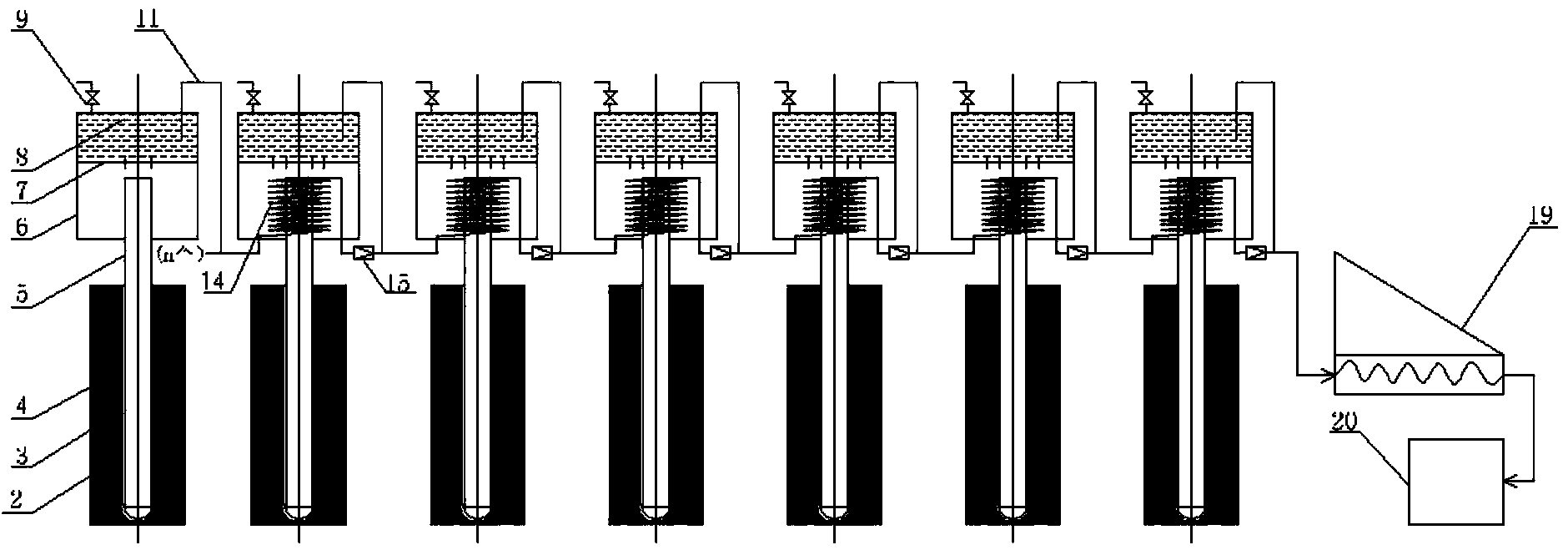

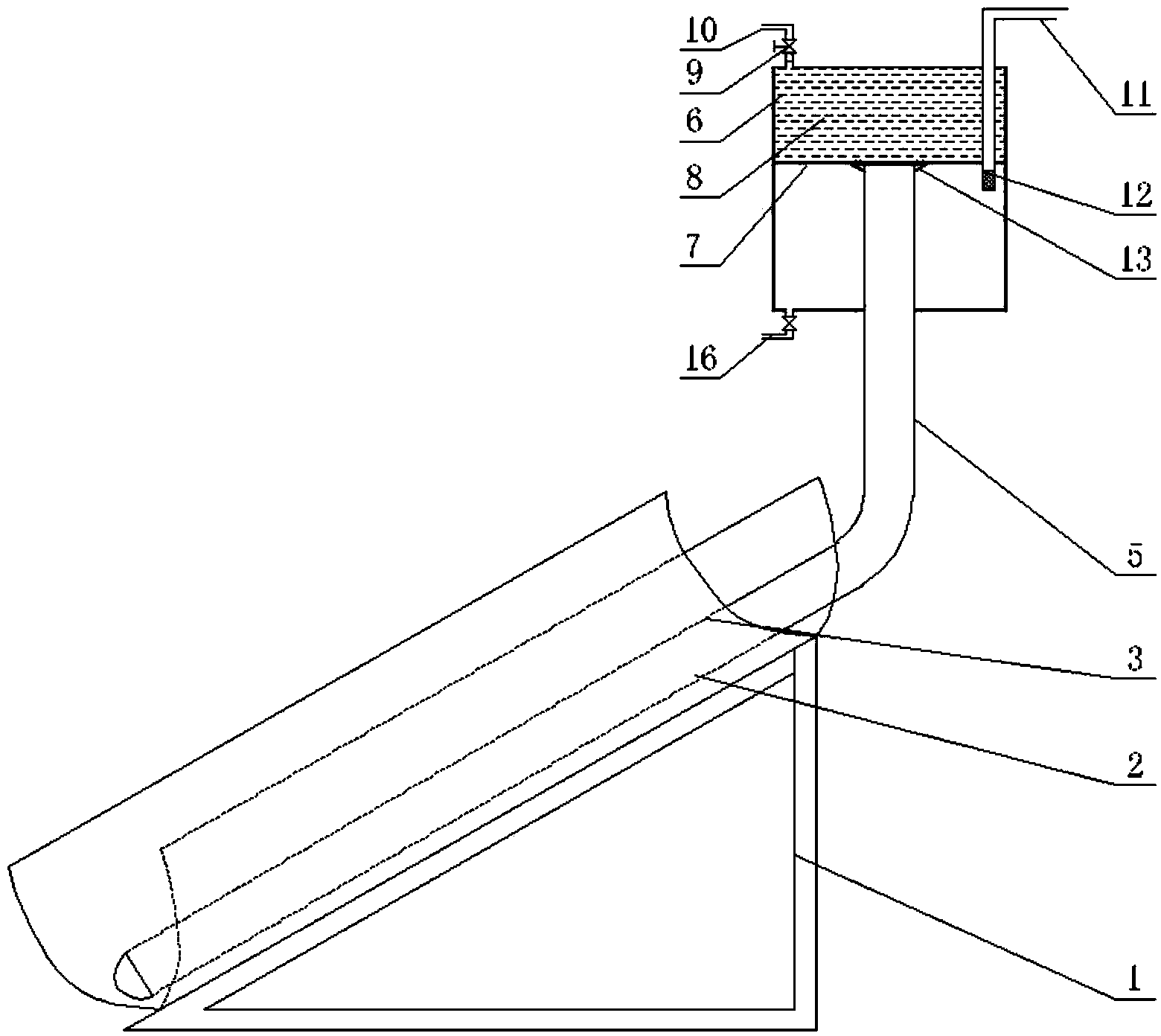

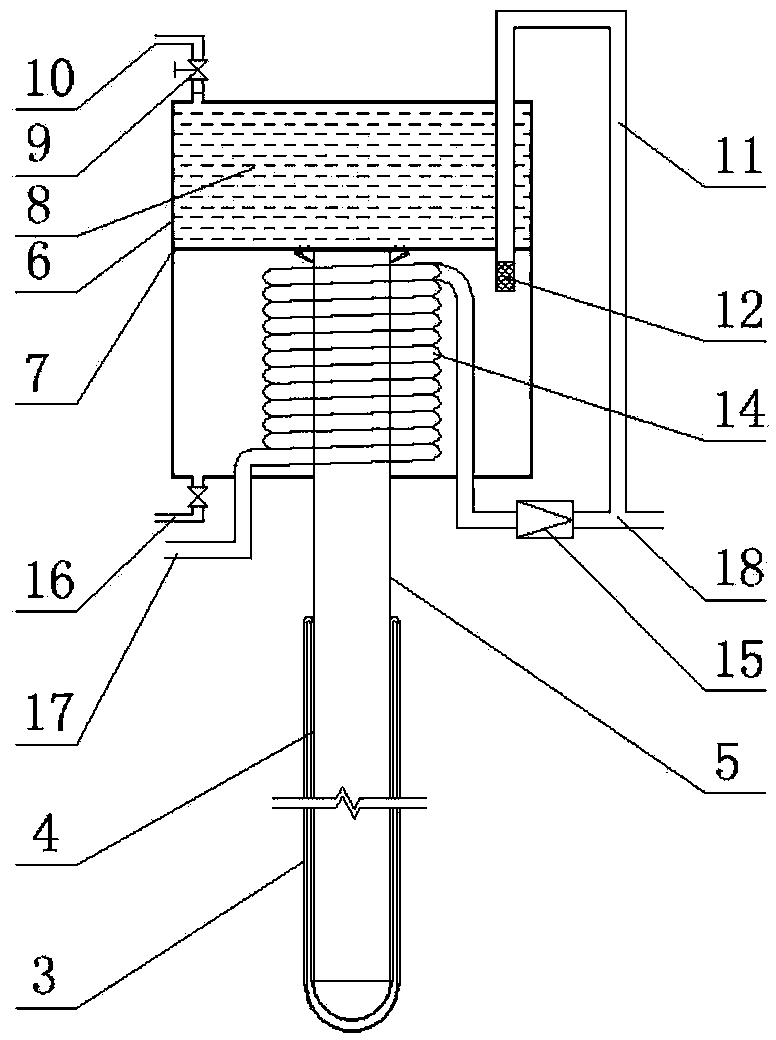

[0043] In this embodiment, the length, width, and height of the CPC concentrator 2 are 1600 mm, 330 mm, and 146 mm, respectively, and the bracket 1 is placed at an angle of 30° to the ground. The seawater desalination device is divided into 8 working stages, including 8 first heat collecting units and 6 second heat collecting units in total, and the first working stage is composed of 8 first heat collecting units connected in parallel. In the first working stage to the seventh working stage, the working temperatures of each working stage are 150°C, 142°C, 134°C, 126°C, 118°C, 110°C and 102°C in sequence. The outer diameter of the all-glass vacuum solar heat collecting tube 3 in each heat collecting unit is 58mm, the inner diameter is 47mm, and the effective length is 1.6m. The outer diameter of the heat pipe 5 is 45 mm and the length is 2.5 m. The inner diameter of the seawater tank 6 is 380mm, and the overall height is 500mm. It is divided into a storage tank and an evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com