Preparation method of reduction graphene oxide heat-conducting film

A graphene film and thermal conductive film technology, applied in the field of materials science, can solve the problems of difficult to maintain a large-area complete structure, easy to break, etc., and achieve the effect of significant technological progress and overcoming easy breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

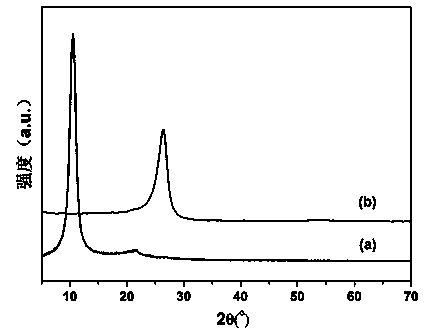

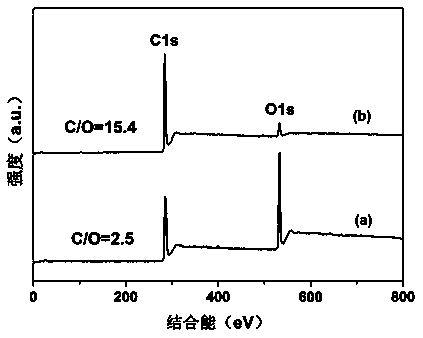

Embodiment 1

[0028] Measure 96mL of concentrated sulfuric acid and place it in a dry container, add 2g of sodium nitrate to it, stir to dissolve the sodium nitrate, then add 2g of flake graphite, after the flake graphite is evenly dispersed, slowly add 12g of potassium permanganate, react for 1.5h, During the whole process, an ice bath was used to keep the system at 0-5°C. Then the temperature was raised to 35°C for 2.5h. Slowly add 80mL of deionized water to the system, react for 10min, then slowly add 200mL of deionized water to the system, and then add 10mL of H 2 o 2 , continue the reaction for 10 min, and filter the above product with suction, and wash the product with suction and filtration with 800mL 5wt% HCl at the same time to remove the metal ions in the solution, and wash the above product repeatedly with deionized water until the solution becomes neutral. The washed product was dried in an oven at 120°C to obtain graphite oxide.

[0029] Add graphite oxide to deionized water...

Embodiment 2

[0040] Graphene oxide was prepared according to the method in Example 1. 200 mg of graphene oxide was weighed, added to 200 mL of solvent, and subjected to ultrasonic treatment for 1 h (100 W, 40 KHz) to obtain a graphene oxide dispersion. Measure 20mL of the above-mentioned graphene oxide dispersion, carry out vacuum filtration with a mixed cellulose microporous filter membrane with a pore size of 0.45 μm, dry the filter cake together with the filter membrane at 80°C for 24 hours, and then peel off the filter cake from the filter membrane to obtain Graphene oxide film, the reduced graphene oxide film is obtained by high temperature treatment.

[0041] Described solvent is the mixed solution that is made into by 100mL deionized water and 100mL ethanol;

[0042] The concentration of graphene oxide in the described graphene oxide dispersion is 1mg / mL;

[0043] The thickness of the graphene oxide film is 10 μm;

[0044] For the high-temperature reduction, the graphene oxide fil...

Embodiment 3

[0047] Graphene oxide was prepared according to the method in Example 1. 1000 mg of graphene oxide was weighed, added to 200 mL of solvent, and subjected to ultrasonic treatment for 1 h (100 W, 40 KHz) to obtain a graphene oxide dispersion. Measure 20mL of the above-mentioned graphene oxide dispersion, carry out vacuum filtration with a mixed cellulose microporous filter membrane with a pore size of 0.45 μm, dry the filter cake together with the filter membrane at 80°C for 24 hours, and then peel off the filter cake from the filter membrane to obtain Graphene oxide film, the reduced graphene oxide film is obtained by high temperature treatment.

[0048] Described solvent is the mixed solution that is made into by 100mL deionized water and 100mL ethanol;

[0049] The concentration of graphene oxide in the described graphene oxide dispersion is 3mg / mL;

[0050] The thickness of the graphene oxide film is 35 μm;

[0051] For the high-temperature reduction, the graphene oxide fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com