A special ultra-thin metal-based diamond cutting sheet for wlcsp packaging chip and preparation method

A technology of ultra-thin metal and cutting blades, which is applied in the direction of stone processing equipment, manufacturing tools, fine working devices, etc., can solve the problems of high price, harsh cutting requirements, and the inability to develop cutting blades, etc. The effect of high degree and strong holding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

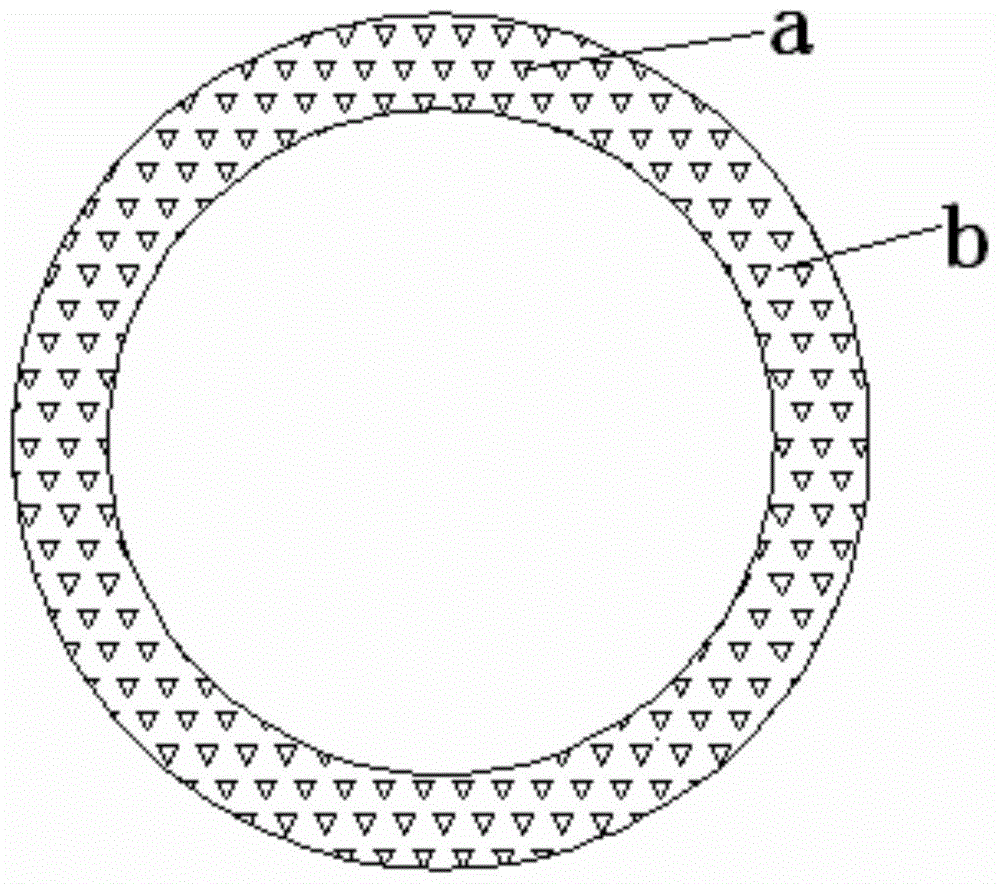

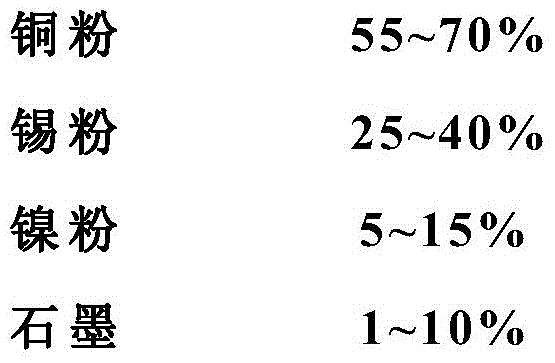

[0034] A special ultra-thin metal-based diamond cutting sheet for WLCSP packaging chips, the components and contents of the metal-based matrix are as follows:

[0035]

[0036] Its preparation method is:

[0037] (1) Mixing: Put the copper powder, tin powder, nickel powder, graphite, diamond (concentration: 20%, particle size: 10 μm) accurately weighed according to the content of the above components into the mixer and mix for 2 hours. After 120# sieve, put it into the container for later use;

[0038] (2) Cold press forming: Put the material into the mold slowly, and gently scrape it with a scraper, place it on the hydraulic press platform together with the mold, and apply a pressure of 3.0*10 3 MPa is made into a shaped compact;

[0039] (3) Hot pressing sintering: put the pressed green body into the sintering furnace, heat up at a rate of 60°C / min, raise the temperature to the final sintering temperature of 550°C, keep it warm for 1 hour, cool it to room temperature wi...

Embodiment 2

[0044] A special ultra-thin metal-based diamond cutting sheet for WLCSP packaging chips, the components and contents of the metal-based matrix are as follows:

[0045]

[0046]

[0047] Its preparation method is:

[0048] (1) Mixing: Put copper powder, tin powder, nickel powder, graphite, diamond (concentration: 30%, particle size: 8 μm) accurately weighed according to the content of the above components into the mixer, and mix for 1 hour. Put it into a container after passing through a 120# sieve;

[0049] (2) Cold press forming: Put the material into the mold slowly, and gently scrape it with a scraper, place it on the hydraulic press platform together with the mold, and apply a pressure of 3.0*10 3 MPa is made into a shaped compact;

[0050] (3) Hot pressing sintering: put the pressed green body into the sintering furnace, heat up at a rate of 60°C / min, heat up to the final sintering temperature of 520°C, keep it warm for 1 hour, cool it to room temperature with the...

Embodiment 3

[0055] A special ultra-thin metal-based diamond cutting sheet for WLCSP packaging chips, the components and contents of the metal-based matrix are as follows:

[0056]

[0057] Its preparation method is:

[0058](1) Mixing: put copper powder, tin powder, nickel powder, graphite, diamond (concentration: 25% particle size: 15 μm) accurately weighed according to the content of the above components into the mixer, mix for 1.5 hours, pass After 120# sieve, put it into the container for later use;

[0059] (2) Cold press forming: Put the material into the mold slowly, and gently scrape it with a scraper, place it on the hydraulic press platform together with the mold, and apply a pressure of 3.0*10 3 MPa is made into a shaped compact;

[0060] (3) Hot pressing sintering: put the pressed body into the sintering furnace, heat up at a rate of 65°C / min, raise the temperature to the final sintering temperature of 500°C, keep it warm for 1 hour, cool it to room temperature with the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com