Label removal device for double-end bottle washing machine

A bottle washing machine, double-ended technology, applied in the direction of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problem of complex structural design of bottle washing machines, poor bottle cleaning effect, and unsuitable for large-scale bottle washing and other issues, to achieve the effects of low production and maintenance costs, simple and practical structural design, and easy cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

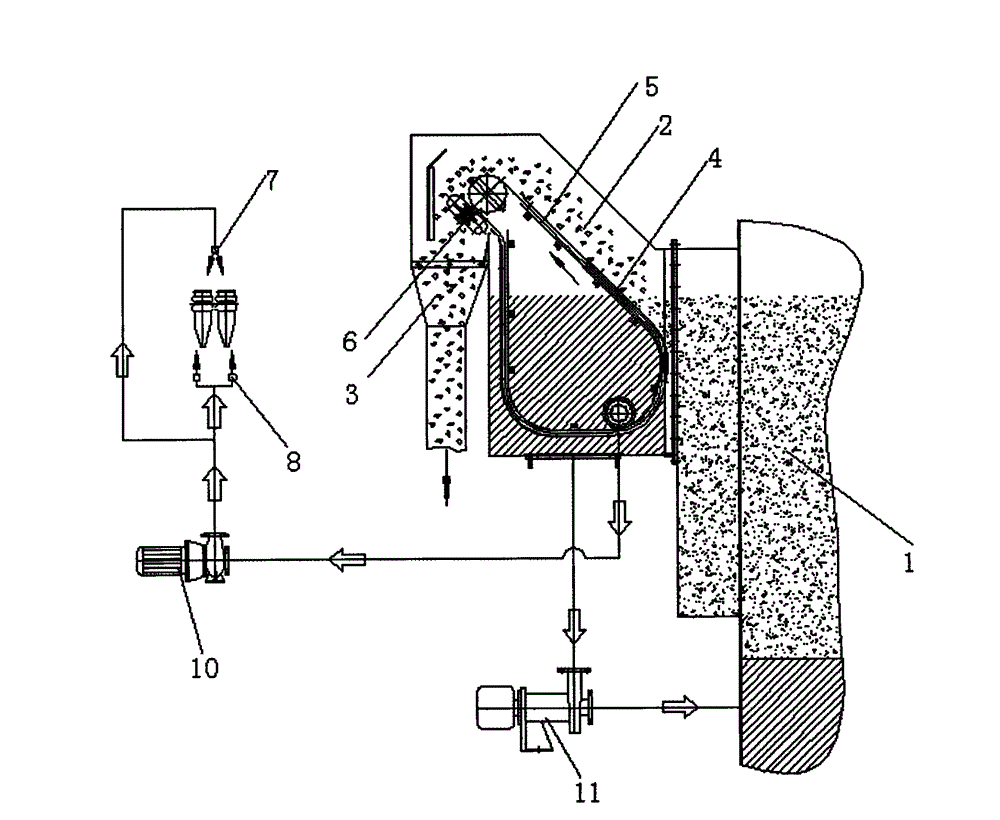

[0012] Refer to the figure, the de-marking device for double-end bottle washing machine includes a soaking tank 1 and a de-marking box 2, which are connected to each other. One side of the de-marking box 2 is connected with a standard paper outlet pipe 3, and the de-marking box 2 has a rotating set There are two closed roller chains. The two roller chains are driven to rotate by rotating the active sprocket and the passive sprocket arranged in the de-marking box 2. The two closed roller chains are covered with a filter chain net 4 to filter The chain net 4 has an upper climbing section 5 connecting the outlet end of the soaking tank and the standard paper outlet pipe. The upper climbing section 5 of the filter chain net 4 is provided with a rotating demarking brush 6 under the top side. The bottom end of the demarking box 2 and the soaking tank The lye circulation pipeline with a large-flow axial flow pump 11 is connected between the bottom ends of 1 to form a rapid water flow. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com