A fuel cell guide plate, fuel cell stack and system

A fuel cell stack and deflector plate technology, applied to fuel cells, fuel cell components, circuits, etc., can solve problems such as air waste, reduced fuel cell system efficiency, and increased mechanical power consumption for air delivery or hydrogen circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

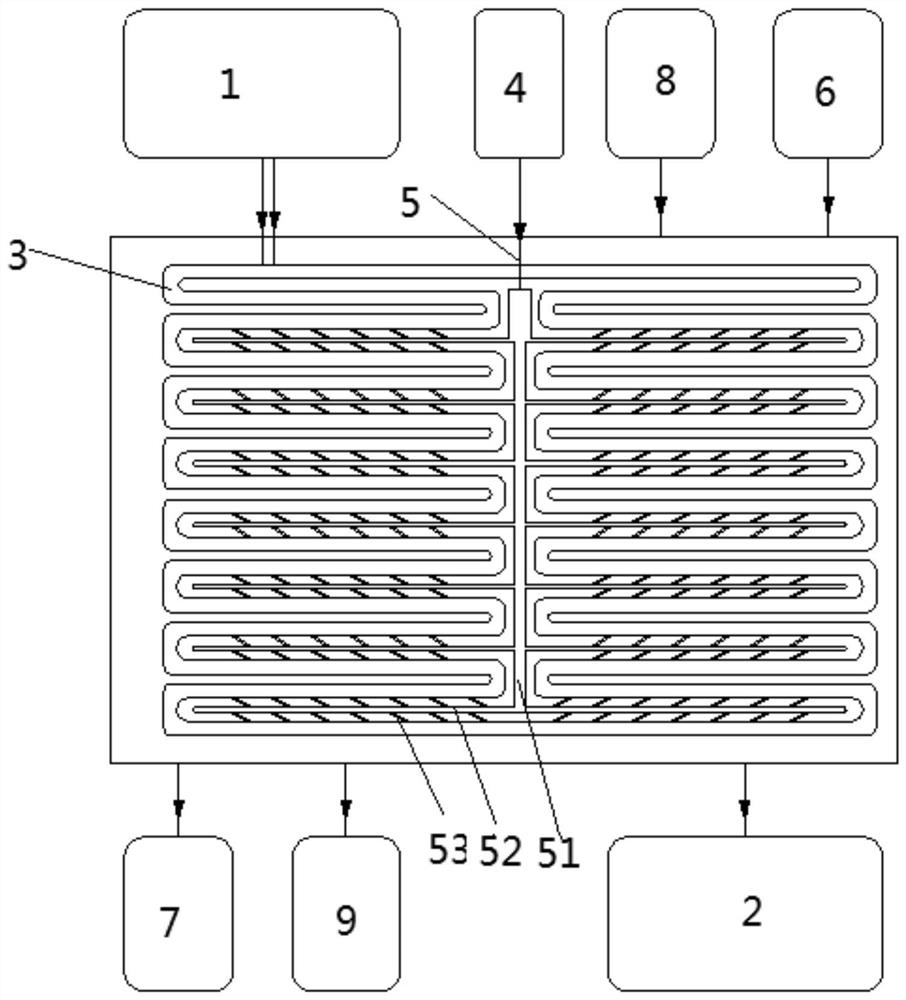

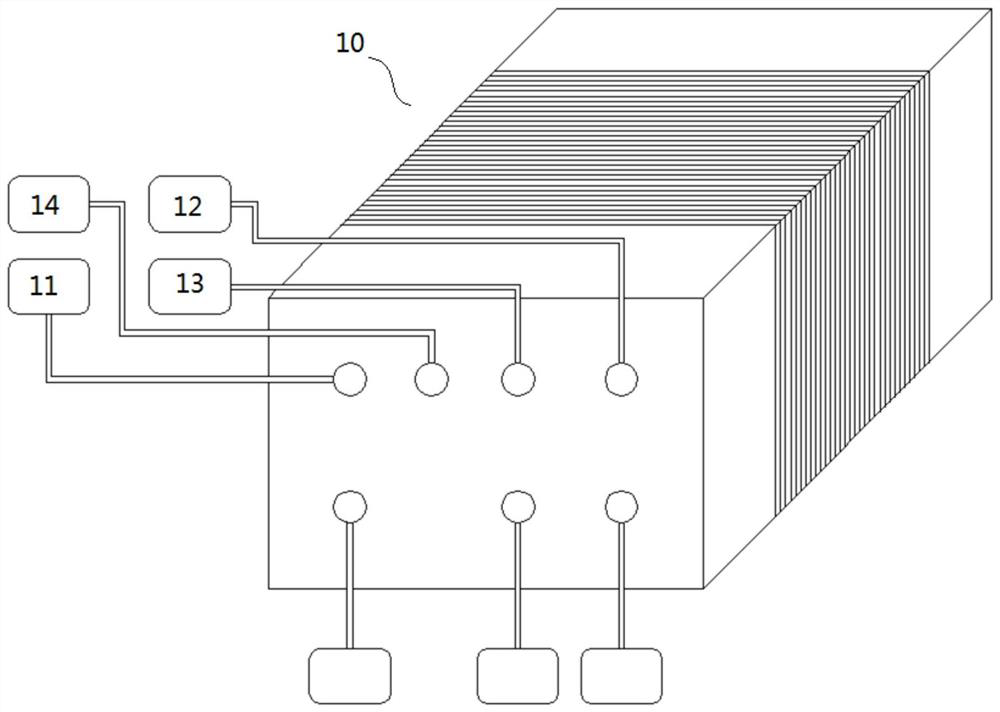

[0029] like figure 1 As shown, the fuel cell guide plate is a conventional fuel cell guide plate, which consists of a front guide air channel plate, a reverse hydrogen guide air flow channel plate, and a middle cooling fluid interlayer, wherein the front guide An oxidant fluid inlet 1 and an oxidant fluid outlet 2 are arranged on the air flow groove plate, and the oxidant fluid inlet 1 and the oxidant fluid outlet 2 are connected through the oxidant main channel 3, the fuel inlet 6, the fuel outlet 7, the cooling fluid inlet 8, the cooling fluid Fluid outlet 9, wherein the reverse hydrogen guide flow channel plate is provided with a fuel guide groove connecting the fuel inlet 6 and the fuel outlet 7, and the middle guide cooling fluid interlayer is provided with a cooling fluid guide connecting the cooling fluid inlet 8 and the cooling fluid outlet 9 groove.

[0030]Add oxidant auxiliary inlet 4 and oxidant auxiliary flow channel 5 on the front guide air flow channel plate of...

Embodiment 2

[0036] The width of the microgrooves 52 is 1 / 2 of the width of the oxidant main channel 3 . The width of the capillary groove 53 is 1 / 3 of the width of the oxidant main channel 3 . The output pressure of the auxiliary oxidant compressor 14 is five times that of the main oxidant compressor 11 . All the other are with embodiment 1.

Embodiment 3

[0038] The width of the microgrooves 52 is 1 / 10 of the width of the oxidant main channel 3 . The width of the capillary groove 53 is 1 / 20 of the width of the oxidant main channel 3 . The output pressure of the auxiliary oxidant compressor 14 is twice that of the main oxidant compressor 11 . All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com