Water supply and drainage pipeline for high-rise building

A high-rise building, water supply and drainage technology, applied in buildings, indoor sanitary plumbing installations, pipes, etc., can solve problems such as easy accumulation of large scale, inability to discharge sewage, loss of spiral strips to guide noise reduction, etc., and achieve the effect of avoiding loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

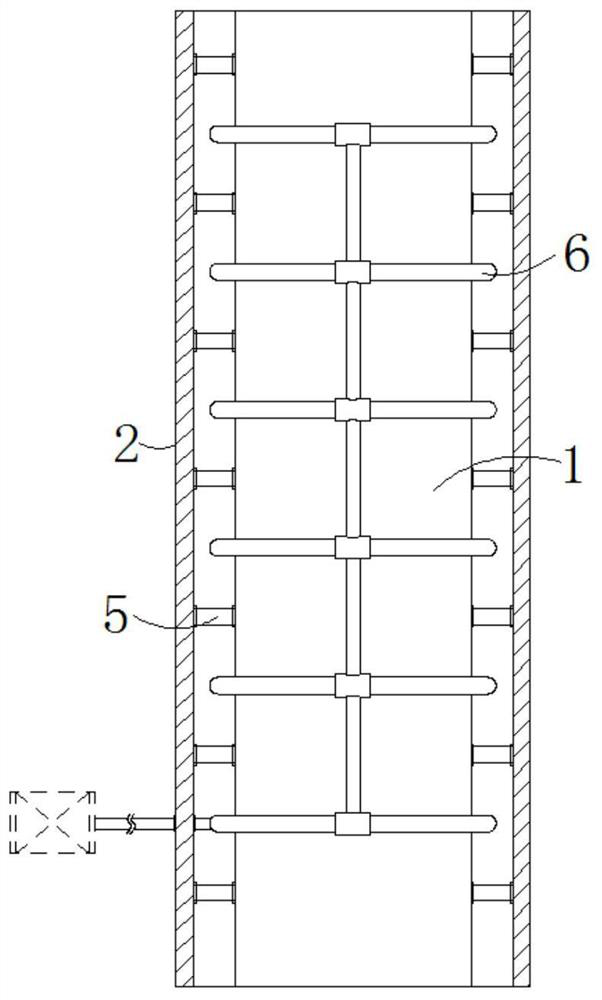

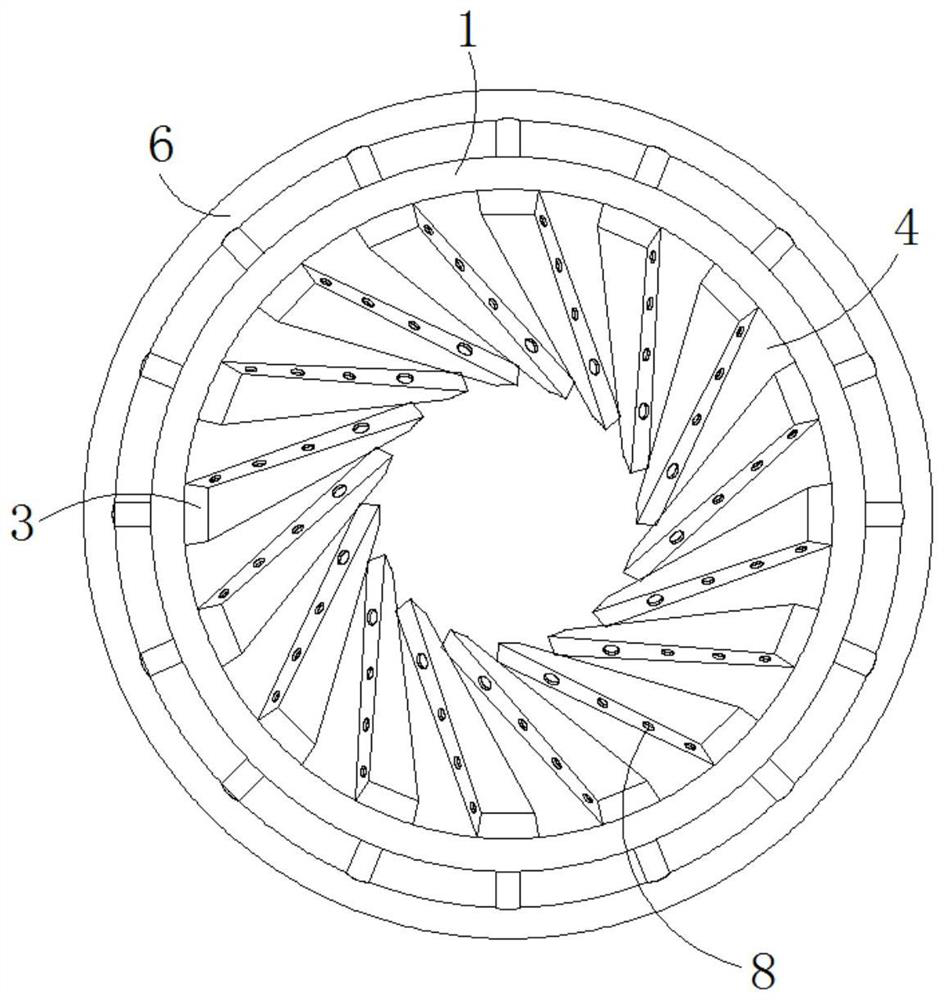

[0035] The pipeline includes an outer pipe 2 and an inner pipe 1 arranged inside the outer pipe 2, and the interconnected inner pipe 1 and the outer pipe 2 are arranged coaxially. The inner wall of the inner pipe 1 is provided with a guide strip 3. Between the guide strips 3 is the concave area 4 , the guide strip 3 and the adjacent concave area 4 jointly guide the water flow down the inner wall of the inner tube 1 along the spiral direction, and also include a buffer device, which is arranged on the outer tube 2 . The space between the inner wall and the outer wall of the inner tube 1 is used to buffer the impact of the water flow in the inner tube 1. In this embodiment, the buffer device is composed of a connecting column 5. The two ends of the connecting column 5 of the elastic structure are respectively connected to the outer tube. The inner wall of 2 and the outer wall of the inner pipe 1 are fixedly connected, and the ring pipe 6 is located between the upper and lower two...

no. 2 example

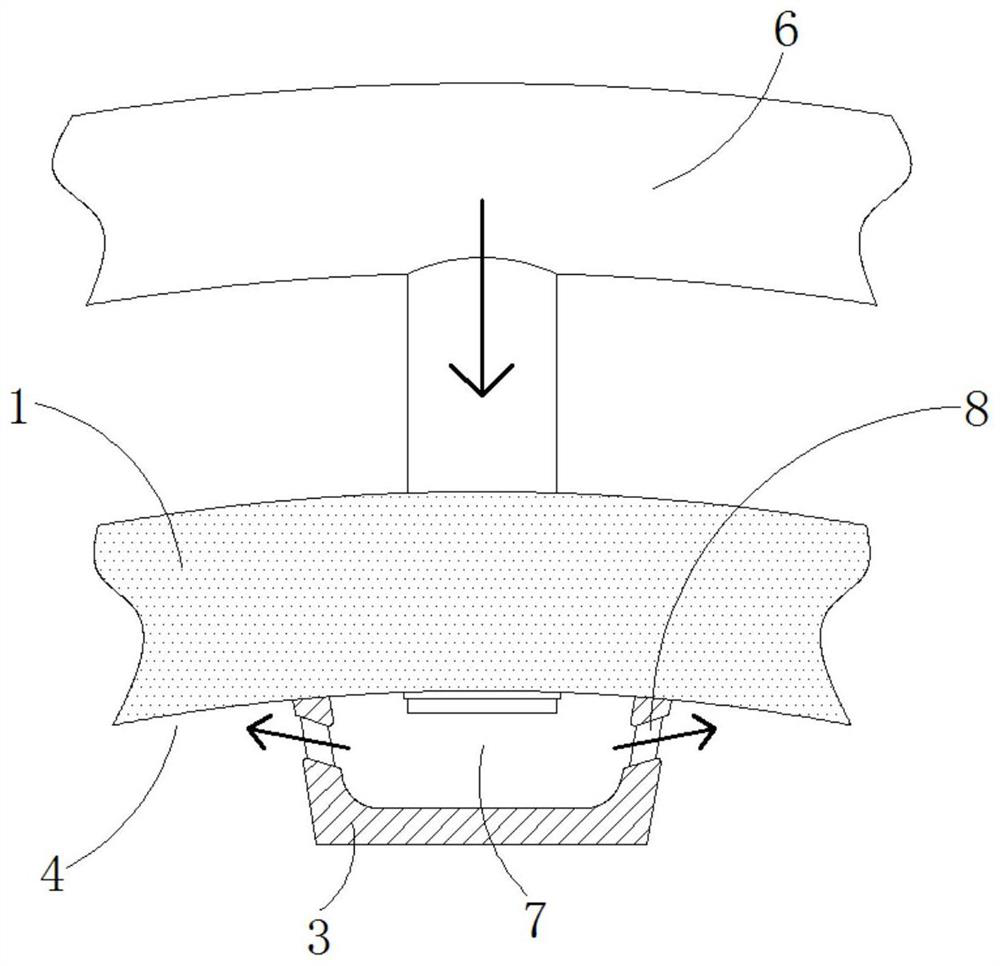

[0038] The difference from the first embodiment is that in this embodiment, in order to make the buffering effect better and the connection between the inner tube 2 and the outer tube 1 more stable, as Figure 4 As shown, the buffer device is the same spirally distributed buffer strip 9, the buffer strip 9 is fixed between the outer tube 2 and the inner tube 1, and the buffer strip 9 and the recessed area 4 are arranged correspondingly inside and outside, while the inner part of the elastic material buffer strip 9 A cavity 11 is provided, and the buffer device provided in this way can further alleviate the impact force by increasing the installation density. Although the cost is slightly higher than that of the first embodiment, its actual effect is as follows. part.

[0039] In this embodiment, the buffer bar 9 as the buffer device can not only buffer the impact force, but also play the role of conveying the circulating medium, such as Figure 5-6 As shown, the cavity 11 is ...

no. 3 example

[0041] The difference between this embodiment and the second embodiment is that the cleaning power source in this embodiment is mainly air flow, such as Figure 7-9 As shown, one end of the cavity 11 is communicated with the ring pipe 6, the cleaning device includes an air cavity 18 and an air hole 17, the other end of the cavity 11 is communicated with the air cavity 18 through the air hole 17, and the air hole 17 is opened on the outer wall of the inner pipe 1. , the air cavity 18 is opened at the concave area 4 and is also spirally distributed as the concave area 4, and the opening of the air cavity 18 is covered with an elastic sheet 19, the ring pipe 6 is connected with the air supply device, and the air supply device passes through the ring pipe 6 and The cavity 11 blows air intermittently into the air cavity 18, the air flow drives the elastic sheet 19 to deform and vibrate intermittently, and the fouling in the depression area 4 is vibrated and cleaned. The air supply d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com