Preparation method of amphoteric polyelectrolyte complex surface-modified polyamide reverse osmosis membrane

A polyelectrolyte and surface modification technology is applied in the field of preparation of polyamide reverse osmosis membranes to achieve the effects of good hydrophilicity, good pollution resistance and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

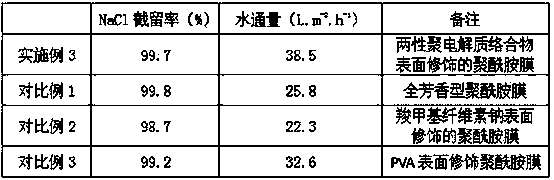

Examples

preparation example Construction

[0015] The preparation method of the polyamide reverse osmosis membrane modified on the surface of the amphoteric polyelectrolyte complex comprises the following steps:

[0016] (1) Dissolve 10-30 parts by mass of zwitterionic monomers and 5-10 parts by mass of cationic monomers in an aqueous solution of 50-200 parts by mass, blow nitrogen into it, and add 0.1-1 parts by mass of water-soluble initiator , at 40-60 o Polymerize at C for 6-12 hours, precipitate the polymer with acetone, and wash it several times to obtain an amphoteric cationic polymer, which is vacuum-dried for later use;

[0017] (2) Dissolve 1-3 parts by mass of sodium carboxymethylcellulose and 0.5-2 parts by mass of amphoteric cationic polymer in 100-500 parts by mass of acidic aqueous solution, and then add the acidic aqueous solution of amphoteric cationic polymer dropwise Carry out ionic cross-linking in the acidic aqueous solution of sodium carboxymethyl cellulose, after precipitation, wash with deioniz...

Embodiment 1

[0021] 10 g of 3-[N,N-dimethyl-[2-(2-methylprop-2-enoyloxy)ethyl]ammonium]propane-1-sulfonic acid inner salt and 5 g of methacrylic acid Dissolve acyloxyethyltrimethylammonium chloride in 50 g of aqueous solution, pass through nitrogen, add 0.1 g of potassium persulfate and sodium bisulfite (mass ratio is 1:1), at 40 o C was polymerized for 12 hours, precipitated with acetone, washed several times, and dried in vacuum to obtain an amphoteric cationic polymer; 1 g of sodium carboxymethylcellulose and 0.5 g of amphoteric cationic polymer were dissolved in 100 g of 0.01wt% hydrochloric acid aqueous solution, then the amphoteric cationic polymer acidic aqueous solution is added dropwise in the sodium carboxymethyl cellulose acidic aqueous solution to carry out ion cross-linking, after precipitation, washed with deionized water several times, at 40 o C dried for 16 hours to obtain the amphoteric polyelectrolyte complex; then the above-mentioned 0.2 g complex was added to 100 g of a...

Embodiment 2

[0023] 30 g of 3-[N,N-dimethyl-[2-(2-methylprop-2-enoyloxy)ethyl]ammonium]propane-1-sulfonic acid inner salt and 10 g of methacrylic acid Dissolve acyloxyethyltrimethylammonium chloride in 200 g of aqueous solution, pass through nitrogen, add 1 g of potassium persulfate and sodium bisulfite (mass ratio: 1:1), at 60 o C was polymerized for 6 hours, precipitated with acetone, washed several times, and vacuum-dried to obtain an amphoteric cationic polymer; 3 g of sodium carboxymethylcellulose and 2 g of amphoteric cationic polymer were dissolved in 500 g of 0.1wt% hydrochloric acid aqueous solution, and then the amphoteric cationic polymer acidic aqueous solution is added dropwise in the sodium carboxymethyl cellulose acidic aqueous solution to carry out ion cross-linking, after precipitation, washed with deionized water several times, at 60 o C dried for 8 hours to obtain the amphoteric polyelectrolyte complex; then the above-mentioned 2 g complex was added to 500 g concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com