Carbon fiber electrostatic actuation type dust-removing filter bag and preparation method thereof

An electrostatic excitation and carbon fiber technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of poor conductivity, large volume resistance, and low surface resistance of filter materials, and achieve low surface resistance and large volume resistance. , the effect of preventing high temperature breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

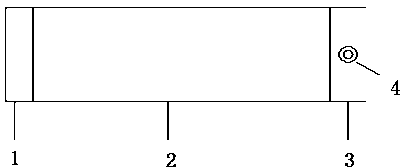

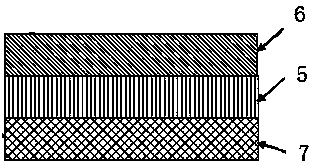

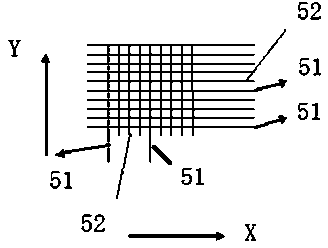

[0018] A carbon fiber electrostatic excitation dust filter bag, figure 1 It is a schematic diagram of the structure of a carbon fiber electrostatic excitation dust filter bag. The filter bag includes a bag head 1, a bag body 2 and a bag bottom 3. Both the bag body and the bag bottom are made of carbon fiber electrostatic excitation filter material mixed with carbon fiber and aramid fiber. The bag head is made of pure aramid fiber filter material. figure 2 It is a structural schematic diagram of carbon fiber electrostatic excitation filter material in the present invention. The carbon fiber electrostatic excitation filter material includes a conductive base cloth 5 , a windward non-woven layer 6 and a leeward non-woven layer 7 . image 3 It is a schematic diagram of the mesh structure of the conductive base cloth in the present invention. The conductive base cloth is woven by stainless steel fiber yarn 51 and aramid yarn 52, and the non-woven layer on the windward side and t...

example 2

[0025] A carbon fiber electrostatic excitation dust removal filter bag, the filter bag includes a bag head 1, a bag body 2 and a bag bottom 3, the bag body 2 and the bag bottom 3 are made of carbon fiber / aramid fiber filter material, the bag head 1 is made of pure aromatic Made of nylon fiber filter material. The carbon fiber electrostatic excitation filter material for preparing the bag body 2 and the bag bottom 3 includes a conductive base cloth 5 , a windward non-woven layer 6 and a leeward non-woven layer 7 . The conductive base fabric 5 is machine-woven from stainless steel fiber yarn and aramid yarn. The windward non-woven layer 6 and the leeward non-woven layer 7 are respectively covered on the upper and lower sides of the base fabric 5. The windward non-woven layer 6 is made of carbon fiber and The aramid fiber is mixed and needle-punched, and the non-woven layer 7 on the leeward side is made of pure aramid fiber by needle-punching. Copper air eyes 4 are installed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com