Polymethylmethacrylate bone cement

A bone cement and polymer technology, applied in surgical adhesives, medical science, tissue regeneration, etc., can solve problems such as increased flow resistance of guiding cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] The invention is explained in more detail in the examples set forth below, which do not, however, limit the scope of the invention.

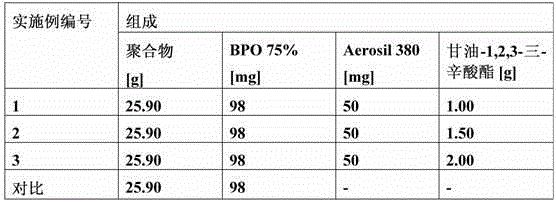

[0107] In Examples 1 to 3 and Comparative Examples, polymethyl methacrylate-co-methyl acrylate (molar mass> 500,000 g / mol) was used; commercially available dibenzoyl peroxide (BPO, with 25 wt% water desensitization), Aerosil® 380 (Evonik) and glyceryl-1,2,3-tri-caprylate (Sigma-Aldrich).

[0108]

[0109] The composition of the monomer liquid was 99.3 wt% methyl methacrylate and 0.7 wt% N,N-dimethyl-p-toluidine. Methyl methacrylate contained 10 ppm hydroquinone as a stabilizer.

[0110] The powdered cement compositions of Examples 1 to 3 and Comparative Example were each mixed with 10 ml of monomer liquid over a period of 30 seconds. In Examples 1-3, this produced a non-dripping cement dough after about 40 seconds with a processing time of about 8-9 minutes. During the processing phase, the sample could be pressed through an 18 G ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bet surface area | aaaaa | aaaaa |

| Bet surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com