Miniature combine harvester

A combination harvester and small-scale technology, which is applied to the chassis of harvesters, cutters, and agricultural machinery, etc., can solve problems such as high labor intensity, poor harvest quality, and poor quality control of parts, so as to improve safe operability and improve The effect of conveying efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment one is as follows:

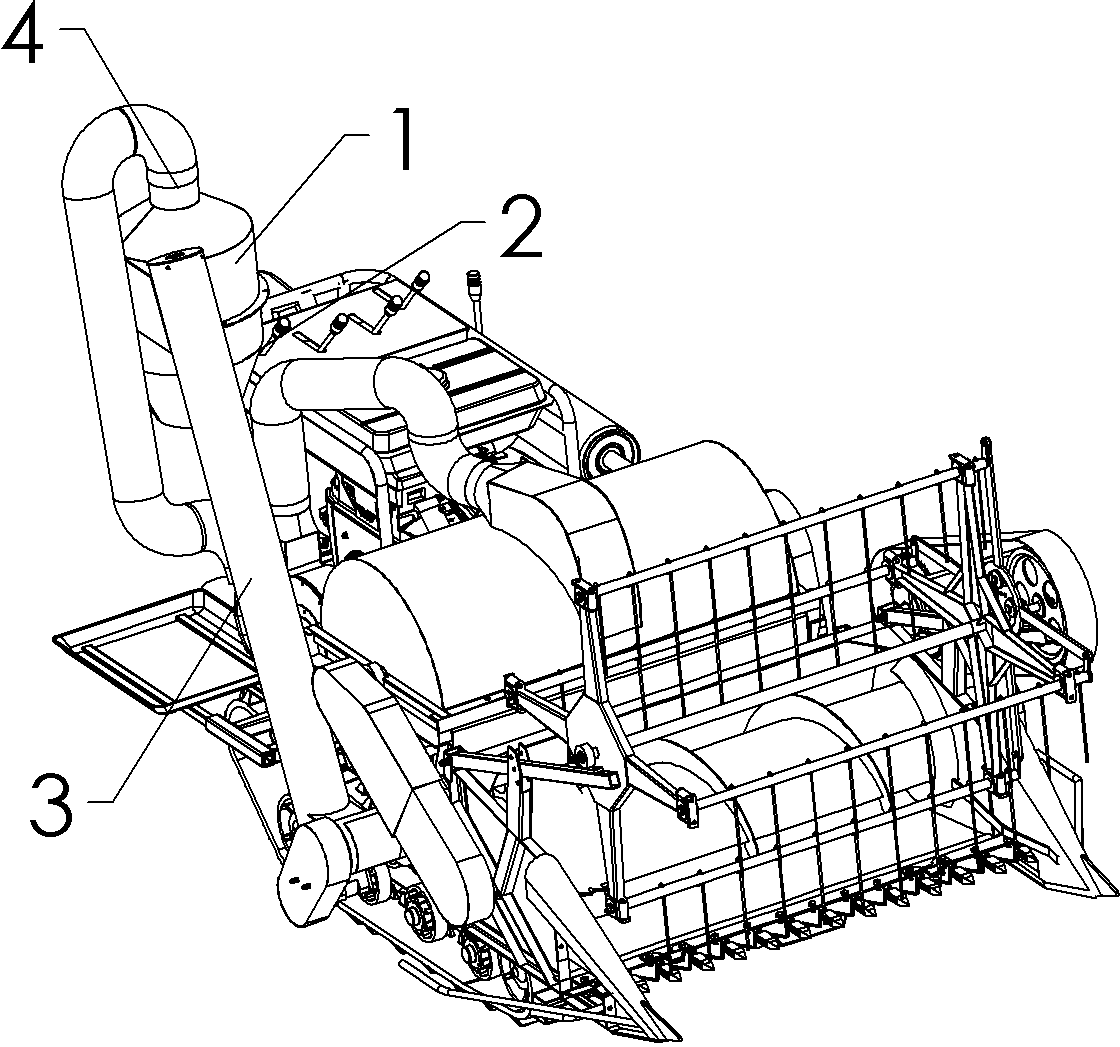

[0039] Such as figure 1 As shown: the main body of the secondary cleaning mechanism is a cyclone separator, which is installed on the combine harvester. The interior of the separator is equipped with a spiral impeller along the axis, and the impeller is driven by a motor.

[0040] There is a horizontal feeding port on the cylindrical part 1, and the feeding port is connected with the thresher of the combine harvesting through the cage conveyor 3. Enter the inside of the cylindrical part 1. A steel wire filter is installed inside the cylindrical part 1 along its cross section, and the steel wire filter is located above the impeller. After the grain enters the cylindrical part 1, it is firstly filtered and roughly selected by the steel wire filter, and the larger particles of impurities are left in the steel wire for filtration. On the wire, grains and smaller impurities can pass through the steel wire filter. An air outlet 34 is opened...

Embodiment 2

[0042] Example two such as figure 2 , 3 , 4 said:

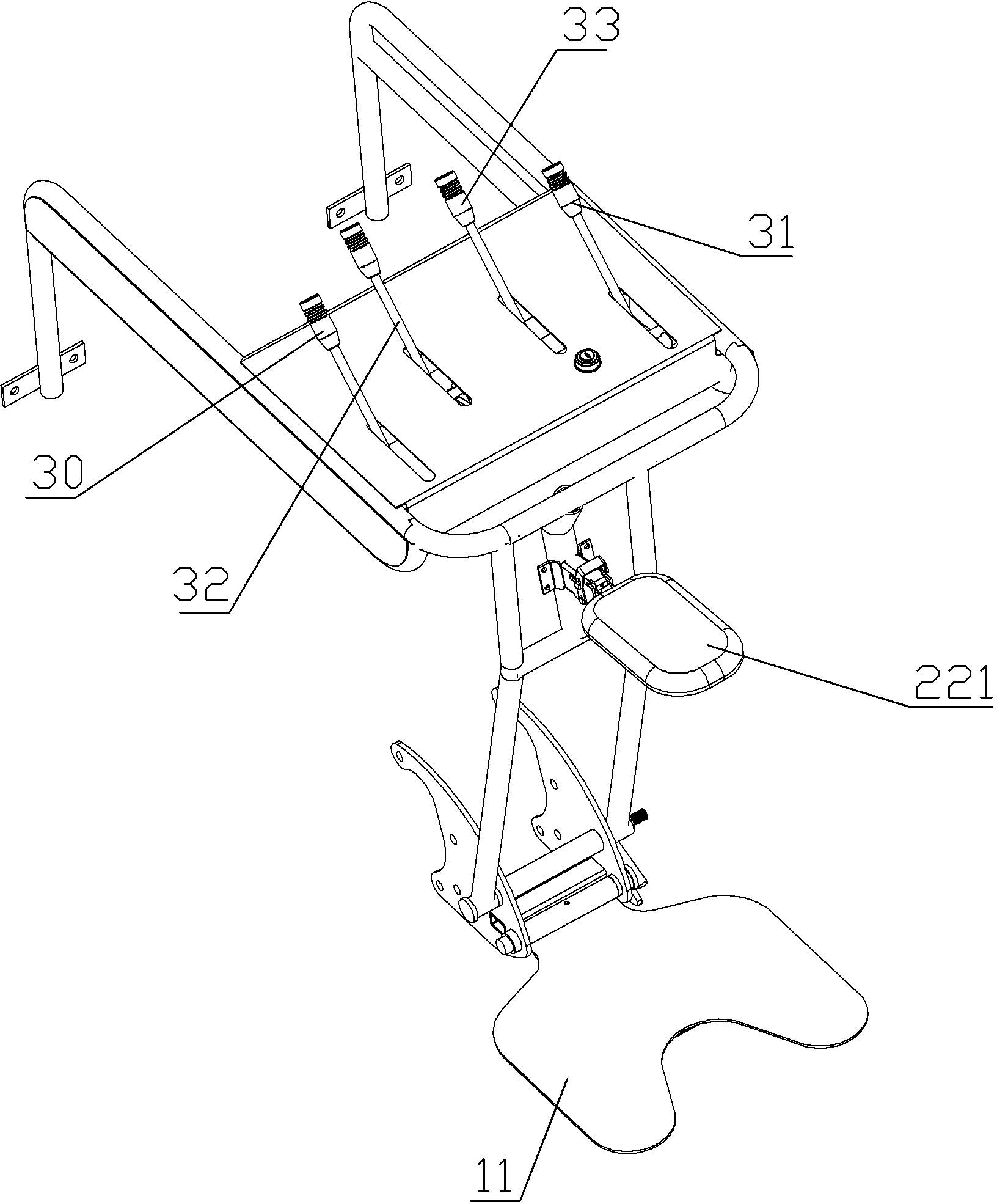

[0043] Such as figure 2As shown, the stand-and-ride operation table includes an operation table fixed by the operation table fixing frame, a foldable stand board connected to the operation table fixing frame and a foldable seat connected to the operation table fixing frame, and the operation table It includes a left steering operating lever 30, a right steering operating lever 31, a threshing operating lever 32, and a walking operating lever 33, wherein the left steering operating lever 30 and the right steering operating lever 31 are used to realize steering through the gearbox 17; the threshing operating lever 32 operates the clutch It provides power for the threshing parts; the walking operation lever 33 operates the clutch to provide power for walking.

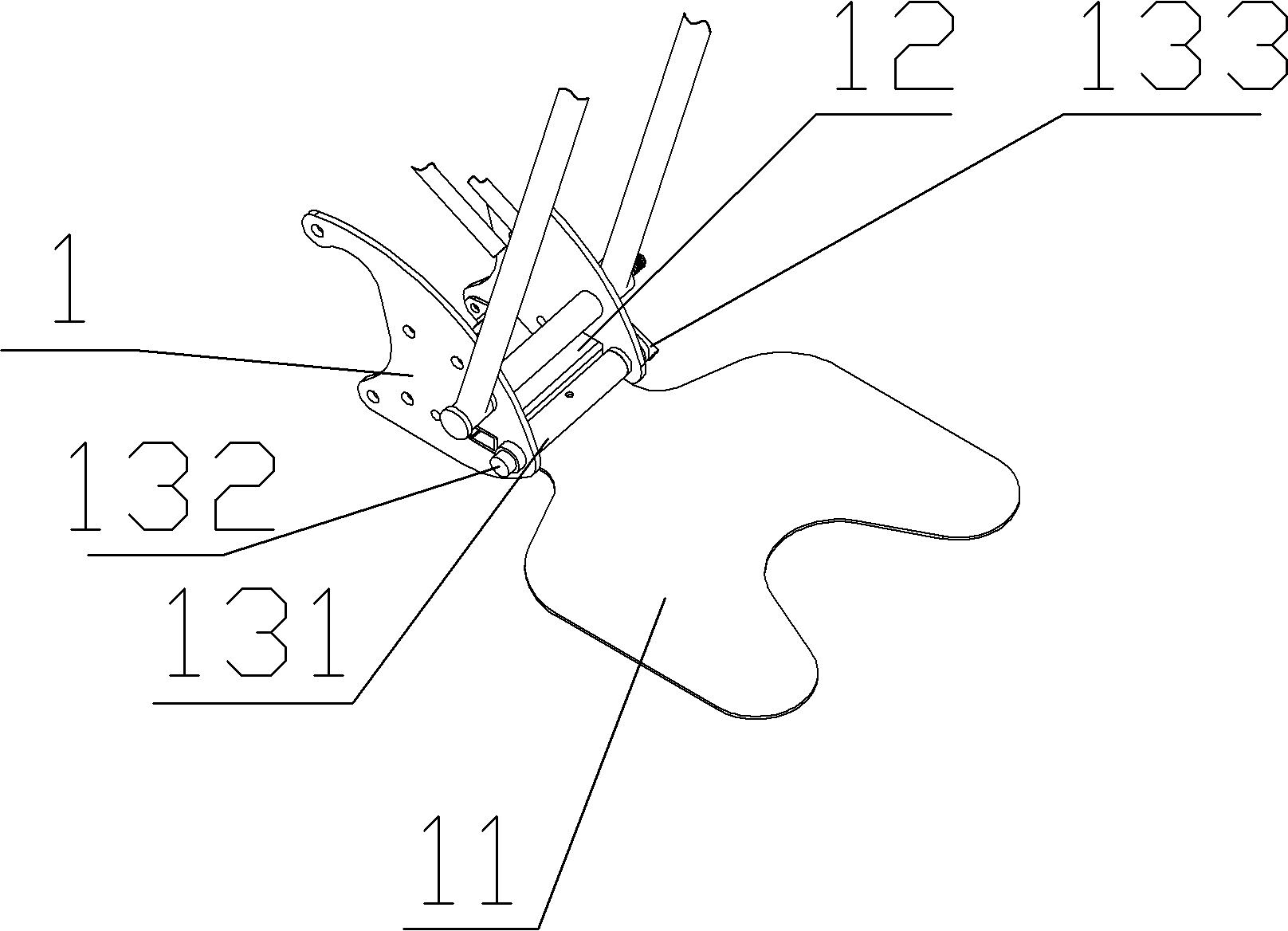

[0044] Such as image 3 As shown, the stand-and-ride operation platform can fold the platform, including a concave-shaped platform 11 with an opening, a stop bar 12...

Embodiment 3

[0048] Embodiment three such as figure 2 , 3 , 4, and 5 show:

[0049] Such as figure 2 As shown, the stand-and-ride operation table includes an operation table fixed by the operation table fixing frame, a foldable stand board connected to the operation table fixing frame and a foldable seat connected to the operation table fixing frame, and the operation table It includes a left steering operating lever 30, a right steering operating lever 31, a threshing operating lever 32, and a walking operating lever 33, wherein the left steering operating lever 30 and the right steering operating lever 31 are used to realize steering through the gearbox 17; the threshing operating lever 32 operates the clutch It provides power for the threshing parts; the walking operation lever 33 operates the clutch to provide power for walking.

[0050] Such as image 3 , Figure 5 As shown, the stand-and-ride operation platform can fold the platform, including a concave-shaped platform 11 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com