No oil mist, energy saving, low consumption air leg rock drill

A rock drill and gas consumption technology, which is applied to reciprocating drilling rigs, mechanical equipment, engine components, etc., can solve problems such as vibration, large recoil force, high impact back pressure, and large internal friction, and achieve convenient refueling operations and lubricating oil savings , the effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

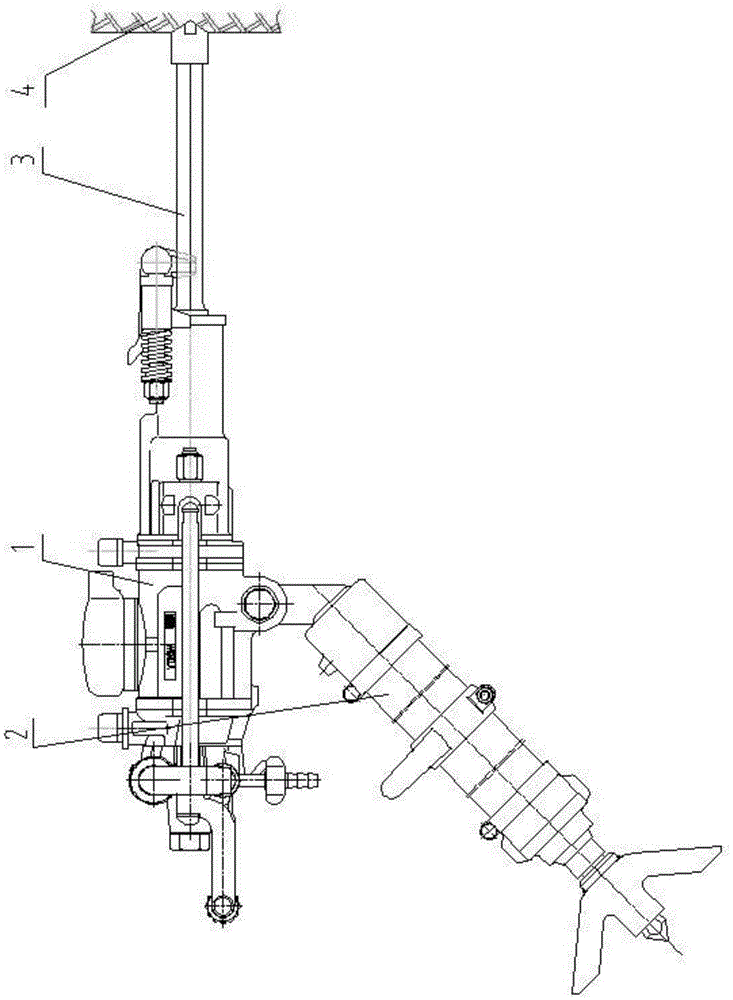

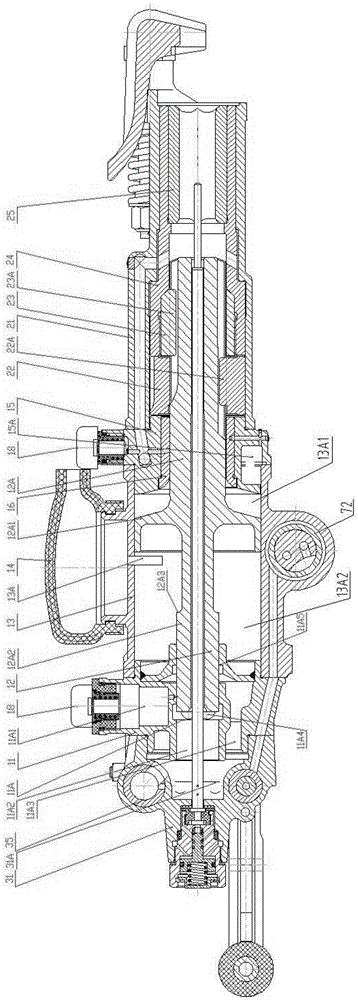

[0061] see figure 1 , The air leg rock drill of the embodiment of the present invention includes a main engine 1, an air leg 2, and a drilling tool 3, and 4 is a rock mass. see figure 2 , the main engine 1 includes a valve body 11 and a handle body 31, a cylinder 13 and a piston 12, a guide body 15 and a guide sleeve 16, a ratchet screw nut 22, a rotating sleeve 24 and a spline sleeve 23, a drill sleeve 25, and a machine head 21. see figure 2 with Figure 13 , Piston 12 is a three-cylinder structure, that is, the front end of the piston is a front striking rod 12A (the right end in the figure is the front), the middle part is a middle large circle 12A1, and the rear end is a rear gas distribution rod 12A2. from figure 2 It can be seen that the front end of the cylinder 13 is fixedly connected with the rear stop of the guide body 15, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com