Solar building roof

A solar building and roofing technology, applied in sustainable building, renewable energy integration, roofing using tile/slate tile, etc. High structural strength and good windproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

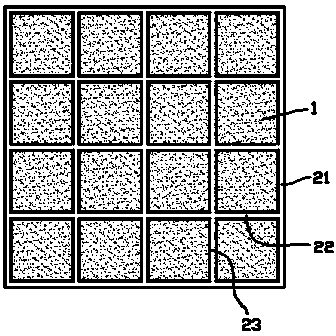

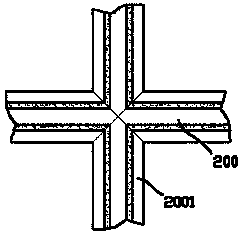

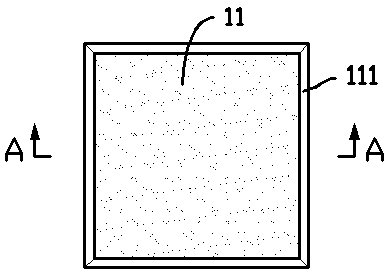

[0028] exist figure 1 In the shown embodiment one, the solar building roof includes a metal frame erected on the roof beams; the metal frame includes a rectangular frame 21 adapted to the size of the roof; the rectangular frame 21 is composed of beams 22 equidistantly distributed , and the equidistant longitudinal beams 23 are divided into a series of sash grids; the rectangular frame 21, cross beam 22, and longitudinal beam 23 are all formed of channel steel 200 with opening grooves upward, and the opening grooves of each channel steel 200 are mutually connected at the intersections. connected, such as figure 2 As shown, it can be connected by welding; rubber pads (not shown) are provided on the two upper edges of the opening grooves of each channel steel 200; the shape and size of each grid match a photovoltaic panel assembly 1; Said photovoltaic module 1 such as image 3 , 4 As shown, it includes a frame box 13 with an opening facing upwards. In the sealed cavity 10 in ...

Embodiment 2

[0037] For the second embodiment, the metal frame is set at a slanting position with the north high and the south low, so as to provide a good lighting angle; in this case, the difference from the first embodiment is:

[0038] Such as Figure 8 As shown, the crossbeam 22 and the longitudinal beam 23 are all relative to the center line of the upper edge and the lower edge of the rectangular frame 21 (ie Figure 8 a-a line) in the oblique distribution, and all the beams 22 and all the longitudinal beams 23 are symmetrical about the center line between the upper edge and the lower edge of the rectangular frame; this structure changes the pattern of the traditional horizontal arrangement of the upper and lower edges of the photovoltaic panel assembly, That is, the photovoltaic panel assembly is laid in an unconventional position, and the benefits obtained are: 1. The supporting edge of each sash for the photovoltaic panel assembly is changed from one to two, which improves the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com