Power integrated multifunctional road pile

An all-in-one, multi-functional technology, applied in the direction of roads, roads, traffic restrictions, etc., can solve the problems of poor sealing effect, high input of manpower and material resources, motor and motor burning, etc., to increase service life, reduce manpower and material resources, and save installation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

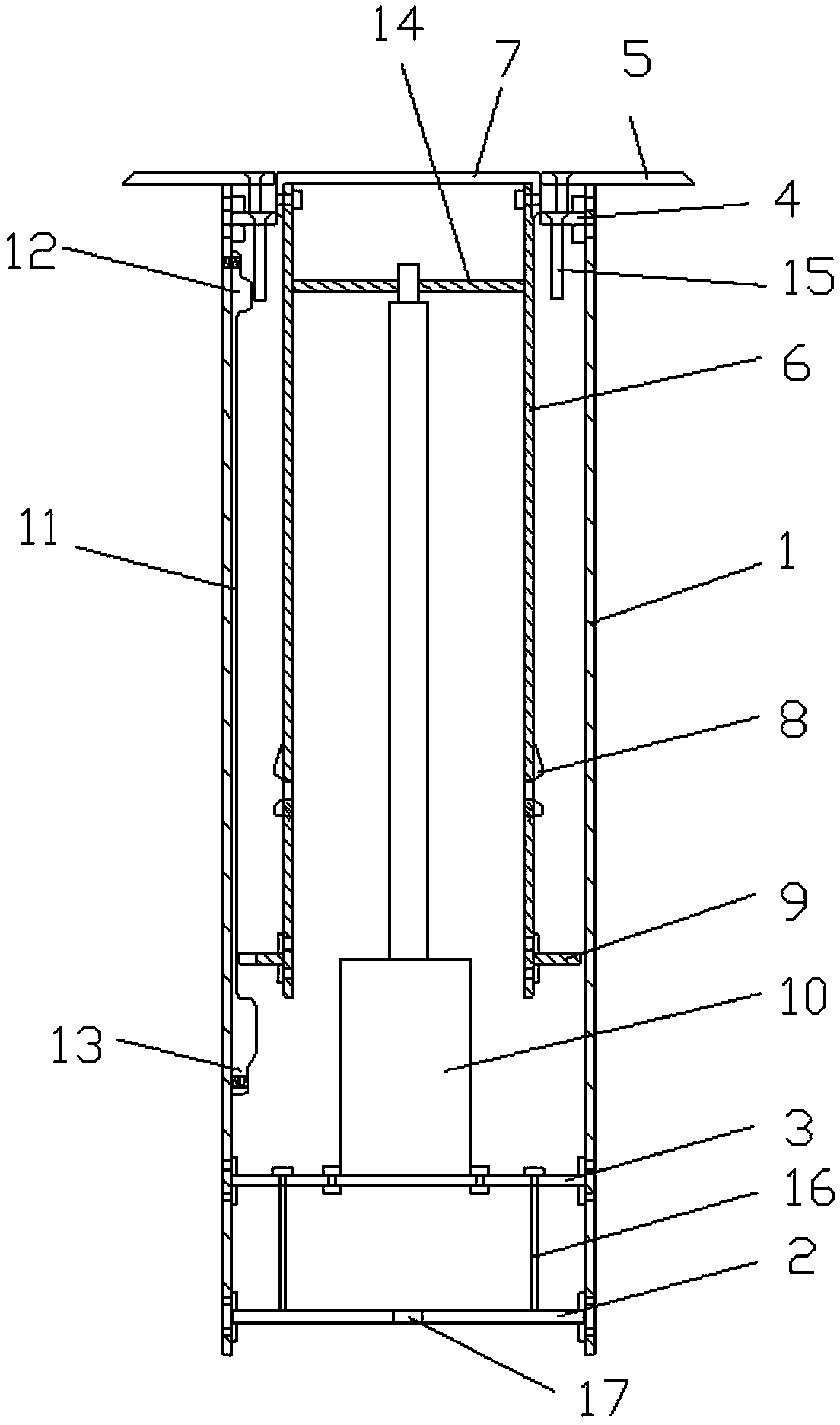

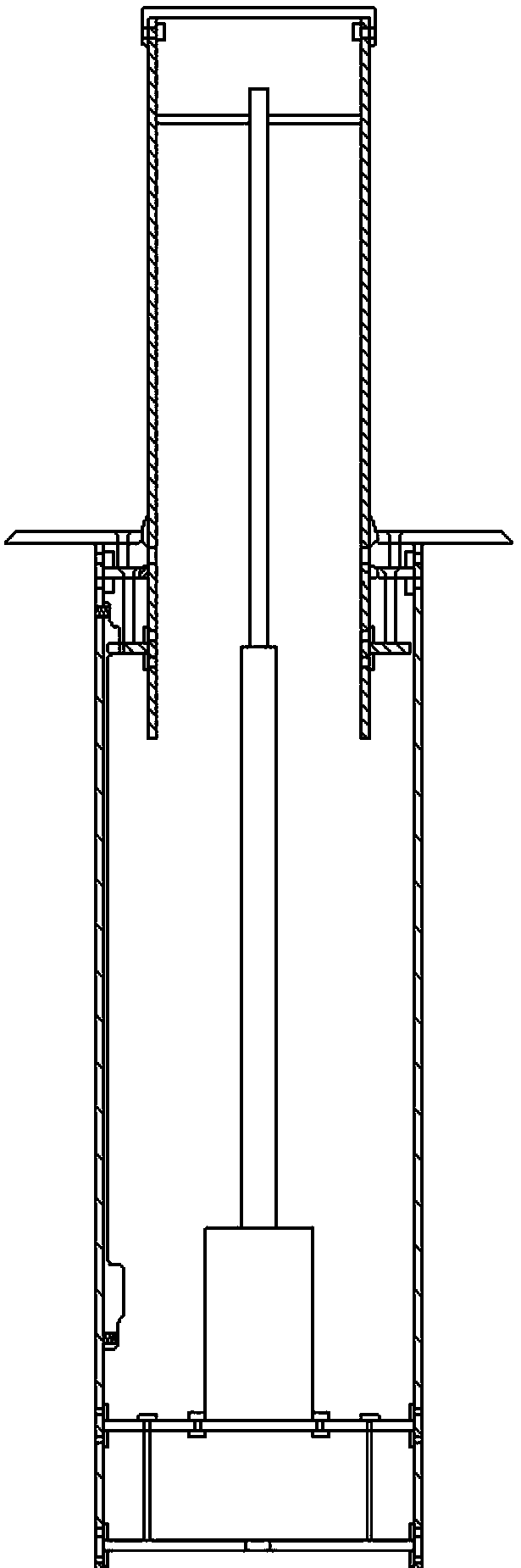

[0023] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0024] refer to Figure 1-2 As shown, a power-integrated multifunctional road pile includes a pre-embedded protection cylinder 1 and a pillar 6. The pillar is set inside the pre-embedded protection cylinder. The power unit 10 that drives the column up and down, the hydraulic lifting device The hydraulic lifting device includes a hydraulic pump and a hydraulic cylinder that are connected to each other, and the motor, hydraulic pump, and hydraulic cylinder are directly connected in sequence to form an integrated structure, and as an integrated The structure is integrally sealed, and the upper end of the hydraulic cylinder is connected to the center of the column support plate 14 provided inside the column. When the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com