Preparation method of titanium foil, titanium foil, and titanium voice diaphragm manufactured by use of titanium foil

A technology of titanium sound film and titanium foil, applied in the field of loudspeakers, can solve the problems of poor ductility of titanium foil, and achieve the effect of good ductility and reduction of sound distortion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing titanium foil. By performing pre-cold rolling on the titanium material blank, the thickness reduction of the titanium material blank is not greater than 20%, and the structure of titanium particles in the titanium material blank is optimized to further reduce the titanium foil for subsequent processes. It provides the basis for improving the thickness of the material and improving the ductility of the resulting titanium foil.

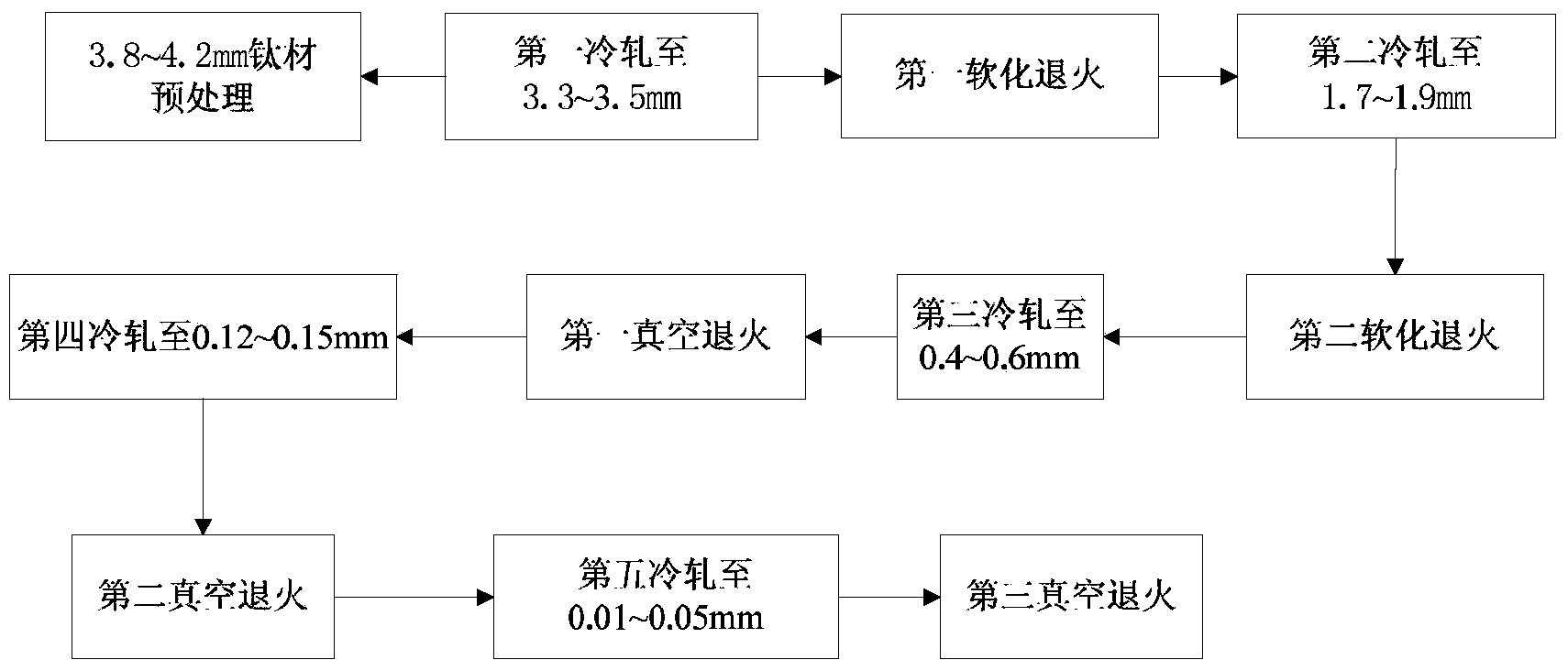

[0026] The process flow chart of the titanium foil preparation method provided by the invention can be found in figure 1 . The method comprises the following steps: subjecting the titanium blank to a first group of cold rolling treatments to form a titanium strip with a thickness of 0.4-0.6mm; and subjecting the titanium strip to a second group of cold rolling treatment to form a titanium foil.

[0027] The ductility of titanium foil is related to the thickness of titanium material used in direct rol...

Embodiment 1

[0051] 1) Select a TA1 hot-rolled coil with a thickness of 3.8mm. The content requirements of impurity elements in this hot-rolled coil are shown in Table 1.

[0052] Table 1 Contents of iron, oxygen and hydrogen elements in TA1 hot-rolled coils

[0053] the element

Fe

O

H

Content%

0.021

0.048

0.002

[0054] 2) The hot-rolled coil with a specification of 3.8*1050mm*C (coil thickness*coil width*coil length) is shot blasted and pickled (impact the upper surface of the titanium coil with metal pellets to loosen the surface scale, and then use nitric acid The surface of the titanium coil is pickled with a mixed ratio of hydrofluoric acid, and the method of finally removing the black scale on the surface of the titanium coil is shot blasting pickling) After that, it is rolled by a wide multi-roll cold rolling mill, and the first cold rolling is to After the thickness of 3.04mm (80%), the first intermediate annealing and shot blasting ...

Embodiment 2

[0059] 1) Select a TA1 hot-rolled coil with a thickness of 4.2 mm. The content requirements of impurity elements in this hot-rolled coil are shown in Table 2.

[0060] Table 2 Contents of iron, oxygen and hydrogen elements in TA1 hot-rolled coils

[0061] the element

Fe

O

H

Content%

0.018

0.036

0.001

[0062] 2) The hot-rolled coil with a specification of 4.2*1050mm*C (coil thickness*coil width*coil length) is shot blasted and pickled and rolled by a wide multi-roll cold rolling mill. The first cold rolling is to 3.5mm ( 83.3%) thickness, the first intermediate annealing and shot blasting pickling are carried out, the first intermediate annealing condition is: 650°C, and the annealing holding time is 30 hours. Then continue the second cold rolling to a thickness of 1.7mm (40%) and carry out the second intermediate annealing and pickling, and then the third cold rolling of the wide multi-roll mill to a titanium strip with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com